gate valve seal

Understanding Gate Valve Seals Importance and Applications

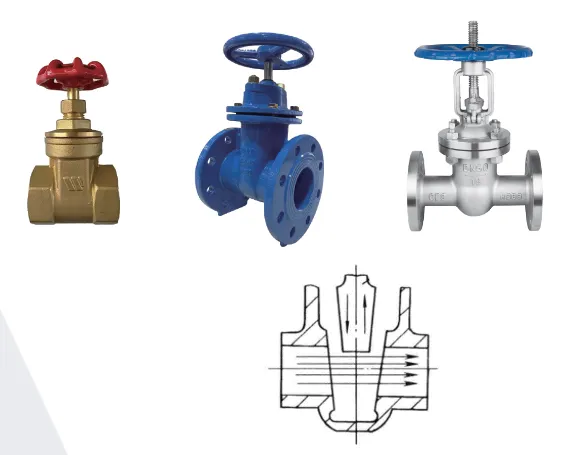

Gate valves are a critical component in various industrial and municipal applications, serving as reliable means to control the flow of liquids and gases. One of the key elements that ensure the functionality and longevity of a gate valve is its seal. Understanding the significance of gate valve seals, their types, materials, and applications can greatly impact the efficiency and reliability of valve operations.

What is a Gate Valve Seal?

A gate valve seal is a sealing mechanism that prevents fluid leakage when the valve is closed. This seal is crucial for maintaining pressure within a pipeline and preventing external contaminants from entering the system. The efficiency of the seal directly affects the valve's performance, making it a vital part of the overall valve design.

Types of Gate Valve Seals

Gate valve seals can be categorized into several types based on their design and function. The most common forms include

1. Soft Seals These seals are made from materials like rubber or elastomer and provide good sealing capability under moderate pressure and temperature. Soft seals are often used in applications where the operating conditions are not extreme.

2. Metal Seals Metal seals are suitable for high-temperature and high-pressure applications. They offer durability and resistance to thermal expansion, making them ideal for industrial use where reliability is paramount.

3. Composite Seals These seals combine both soft and metal sealing properties, offering flexibility and strength. Composite seals are increasingly being used in advanced applications where traditional materials may fall short.

Materials Used in Gate Valve Seals

The choice of material for gate valve seals is critical as it influences the performance, longevity, and compatibility of the valve with different media

. Some commonly used materials include- Nitrile Rubber (NBR) Excellent for general applications, NBR provides good resistance to oil and gas, making it a popular choice in various industries.

- Polytetrafluoroethylene (PTFE) Known for its chemical resistance, PTFE is often used in environments involving aggressive media. Its non-stick properties also contribute to lower friction in valve operations.

- Viton This fluoropolymer elastomer is ideal for applications involving high temperatures and aggressive chemicals, providing a long service life and excellent sealing.

gate valve seal

- Stainless Steel Used in metal seals, stainless steel provides robustness and is resistant to corrosion, making it suitable for harsh environments.

Significance of Proper Sealing

The effectiveness of a gate valve seal significantly impacts several factors, including

1. Leakage Prevention A properly functioning seal prevents leaks, which can lead to environmental hazards and safety concerns. Leakage can also result in operational inefficiencies, increasing costs and downtime.

2. Performance Efficiency With a good seal in place, the gate valve can operate at optimal efficiency, ensuring that the flow control is precise. This is particularly important in industries such as oil and gas, water supply, and chemical processing.

3. Longevity of Equipment Effective sealing minimizes wear and tear on the valve components, extending the overall lifespan of the valve and reducing the need for replacements or repairs.

Applications of Gate Valve Seals

Gate valves and their seals are widely used across various sectors. Some of the notable applications include

- Water Supply Systems In municipal water distribution systems, gate valves help manage water flow and prevent backflow, with seals ensuring leakage-free operation.

- Oil and Gas Industry Gate valves are essential for controlling the flow of hydrocarbons, where durable seals are necessary to withstand high pressures and aggressive chemicals.

- Chemical Processing Plants Gate valves equipped with specialized seals are crucial in processes involving corrosive substances, ensuring safety and efficiency.

Conclusion

In conclusion, gate valve seals are integral to the operation and reliability of gate valves in numerous applications. Understanding the different types of seals, their materials, and their significance can lead to better maintenance practices and improved valve performance. In an era where operational efficiency and safety are paramount, investing in quality gate valve seals is not just an option—it's a necessity. Whether in municipal water systems, industrial processes, or oil and gas operations, ensuring the integrity of gate valve seals is essential for effective flow control and system longevity.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025