Top Manufacturers of ANSI Flanges for Reliable Industrial Applications and Solutions Worldwide

Understanding ANSI Flange Manufacturers A Comprehensive Guide

Flanges are essential components in various piping systems, enabling the connection of pipes, valves, pumps, and other equipment. Among the myriad standards governing flanges, the American National Standards Institute (ANSI) holds a significant position. ANSI flanges are widely used across industries such as oil and gas, water treatment, chemical manufacturing, and power generation, making ANSI flange manufacturers pivotal to these sectors.

What Are ANSI Flanges?

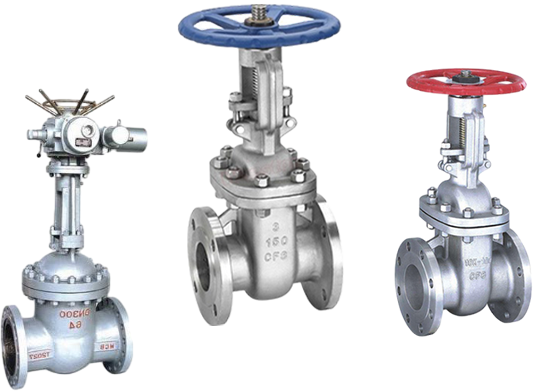

ANSI flanges are standardized flanges defined by the American National Standards Institute. The ANSI standards outline specific design requirements, dimensions, and performance criteria for flanges, ensuring interoperability and safety in piping systems. These flanges are available in various types, including welding neck, slip-on, blind, threaded, and socket weld, each serving unique functionalities.

Flanges are categorized by their pressure ratings, which range from 150 to 2500 psi. Higher pressure ratings indicate a thicker flange, capable of enduring more stress, making them suitable for rigorous applications. The material composition of ANSI flanges also varies; they can be made from carbon steel, stainless steel, alloy steel, and even plastic, catering to different environmental conditions and chemical compositions.

Roles of ANSI Flange Manufacturers

ANSI flange manufacturers play a crucial role in supplying these critical components. Their primary responsibilities include

1. Design and Production Manufacturers must follow ANSI standards closely to design flanges that meet specifications. This involves precise engineering and the use of advanced manufacturing processes such as forging, machining, and welding.

2. Quality Assurance The production of ANSI flanges involves rigorous quality control measures. Manufacturers implement testing procedures to ensure that the flanges can withstand the required pressures, temperatures, and various environmental conditions. This includes non-destructive testing methods to identify any potential flaws in the material.

3. Customization Many projects require custom flange solutions tailored to specific needs. Reputable manufacturers are equipped to provide customized designs, whether it's unique dimensions, bolt patterns, or material specifications.

ansi flange manufacturers

4. Compliance and Certification ANSI flange manufacturers must ensure that their products comply with relevant industry standards and regulations. This compliance not only enhances safety but also builds trust with clients.

5. Supply Chain Management Efficient supply chain management is critical in the flange manufacturing industry. Manufacturers often maintain a stock of standard products while managing lead times for custom orders to meet their clients' timelines.

The Importance of Choosing the Right Manufacturer

Selecting the right ANSI flange manufacturer can substantially impact the overall efficiency and safety of a project's execution. Here are some factors to consider when choosing a manufacturer

- Experience and Reputation Manufacturers with a proven track record and positive customer feedback are more likely to deliver high-quality products.

- Technological Capabilities Advanced manufacturing technologies can streamline production and improve product quality.

- Certifications Look for manufacturers with relevant industry certifications, such as ISO certification, which indicates a commitment to quality and continuous improvement.

- Customer Support A manufacturer that offers excellent customer support can provide valuable assistance throughout the design, production, and installation processes.

Conclusion

ANSI flange manufacturers play an indispensable role in various industries by providing critical components that ensure the safety and efficiency of piping systems. By understanding the importance of these manufacturers and the factors influencing their selection, businesses can make informed decisions that lead to successful project outcomes. Whether through standard products or custom solutions, the commitment of ANSI flange manufacturers to quality and compliance is vital in meeting today’s demanding industrial needs.

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025