Basic knowledge: principles, features and use occasions of different valves

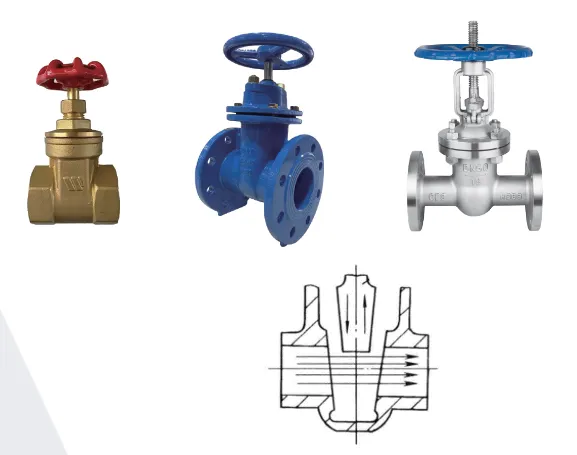

Gate valve

Working principle: There is a gate opening and closing part inside the valve body. The movement direction of the gate is perpendicular to the direction of the fluid. Because it can block water like a sluice, it is called a gate valve

Advantages and disadvantages: Advantages include small flow resistance; opening and closing are more labor-saving; medium flow direction is not restricted; when fully open, the sealing surface is less eroded by the working medium than the stop valve.

Disadvantages include large external dimensions and opening height, and large space required for installation; during opening and closing, there is relative friction between the sealing surfaces, which is easy to cause scratches; the gate valve has two sealing surfaces, which makes processing, grinding and maintenance more difficult; the opening and closing time is long.

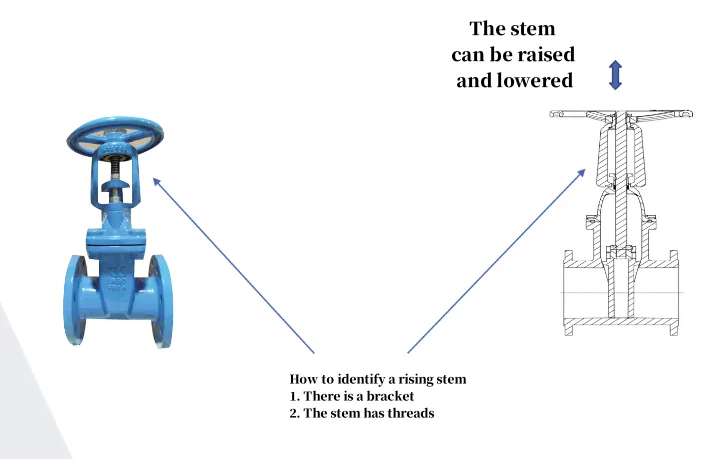

Rising stem gate valve

Difference: The rising stem gate valve has an exposed stem, and the degree of opening and closing is more intuitive, but the stem is also corroded Scope of application: Fire water pump outlet pipe, water suction pipe; outlet pipe, water suction pipe of pressure regulating pump; fire water supply network

Non-rising stem gate valve Difference: Compared with the rising stem gate valve, the non-rising stem gate valve has a non-exposed stem, and the degree of opening and closing is not intuitive, and the installation space is small, which is suitable for concealed projects Scope of application: Fire water pump suction pipe; Fire water supply network

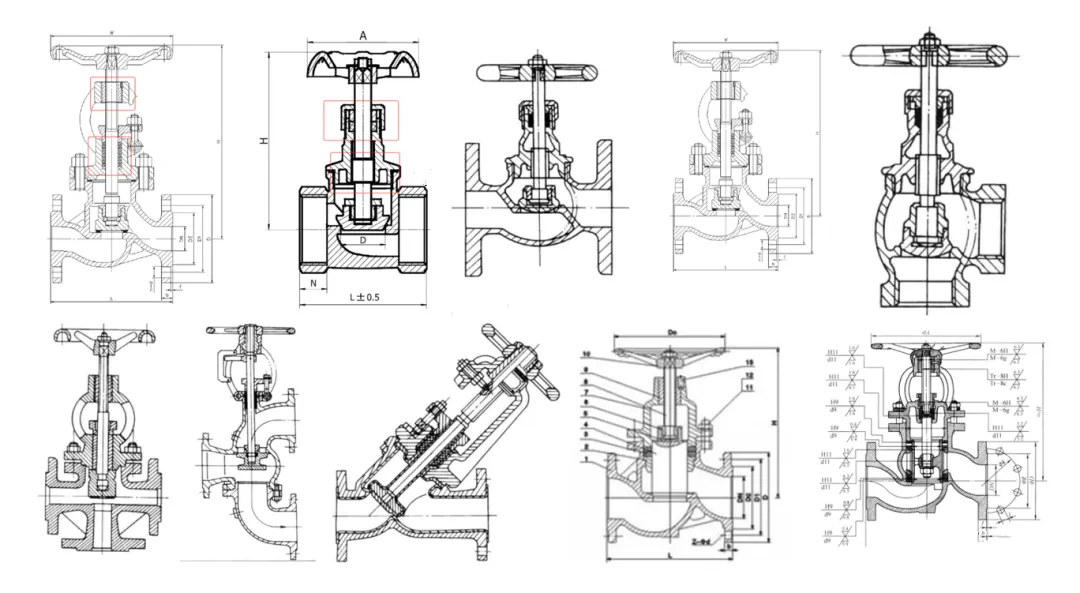

Globe valve

Working principle: Also known as the gate valve, a forced sealing valve, the closing part is driven by the valve stem to move up and down along the center line of the valve seat. The opening or closing stroke of the stop valve is relatively short, and it has a very reliable shut-off action.

Classification of globe valves:

Top threaded stem globe valve

Lower threaded stem globe valve

Straight-through globe valve

Angle globe valve

Three-way globe valve

DC globe valve

Plunger globe valve

Needle globe valve

Advantages and disadvantages of globe valves:

Advantages: The friction of the sealing surface is smaller than that of the gate valve during opening and closing, and it is wear-resistant; the opening height is smaller than that of the gate valve, generally 1/4 of the valve seat diameter; one sealing surface, easy to maintain.

Disadvantages: The flow resistance coefficient is large, causing a large pressure loss; the opening and closing torque is large; the sealing surface may clamp solid particles; pay attention to the inlet and outlet direction when selecting.

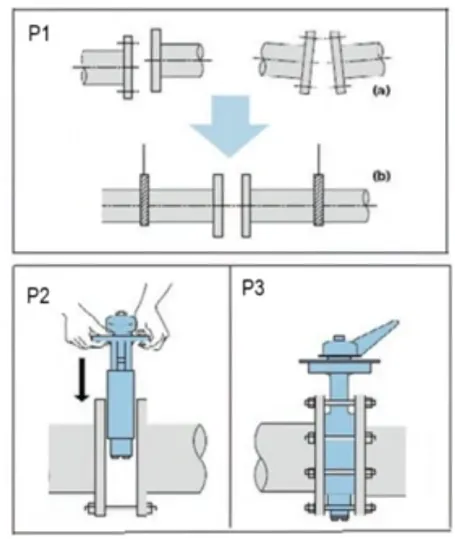

Butterfly valve

Working principle: The closing part (valve disc or butterfly plate) is a disc, which rotates around the valve axis to achieve opening and closing.

Scope of application: Fire water pump outlet pipe, water suction pipe; indoor overhead pipeline.

Supplementary explanation: The applicability of butterfly valves is similar to that of gate valves, and some provisions require them to have self-locking functions.

Common installation and use precautions:

- For butterfly valves ≥DN450, a solid foundation should be set

- 2. The installation test flange should use a special flange for wafer butterfly valves (standard flat flanges)

- 3. The valve is used for water pipelines. The working temperature is -20~+120°C

- 4. The maximum working pressure of the valve at the corresponding temperature is less than its rated pressure

- 5. Do not weld or repair the valve or apply surface coating during operation

- 6. The valve must not be disassembled when under pressure

- 7. When using the valve, please check it once every three months

- 8. The system pressure test and each water flow should be slowly pressurized, and the instantaneous pressure should not be higher than 1.1 times the rated pressure, otherwise there is a risk of damaging the sealing structure.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsМэдээJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesМэдээJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlМэдээJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesМэдээJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyМэдээJul.09,2025

-

Everything You Need to Know About Butterfly ValvesМэдээJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesМэдээJul.08,2025