6 butterfly valve

Understanding the 6% Butterfly Valve A Comprehensive Overview

Butterfly valves are essential mechanical devices used in various industries for regulating flow. Among the numerous types available, the 6% butterfly valve stands out due to its unique features and applications. In this article, we will explore the design, functionality, and significance of the 6% butterfly valve.

1. What is a Butterfly Valve?

A butterfly valve is a quarter-turn valve that consists of a rotating disc or “blade” that regulates flow through a pipe. When the handle is turned, the disc turns 90 degrees around its axis, allowing or blocking the flow of fluid. Due to its simple design, butterfly valves are compact, lightweight, and ideal for applications requiring quick operation.

2. The Significance of the 6% Butterfly Valve

The term 6% in butterfly valves typically refers to the angle of the valve's disc in a partially open position. Specifically, it denotes that the valve opens up to 6% of its total aperture, allowing a controlled flow rate. This precise control is particularly crucial in processes where maintaining a specific flow rate is vital.

3. Design Features

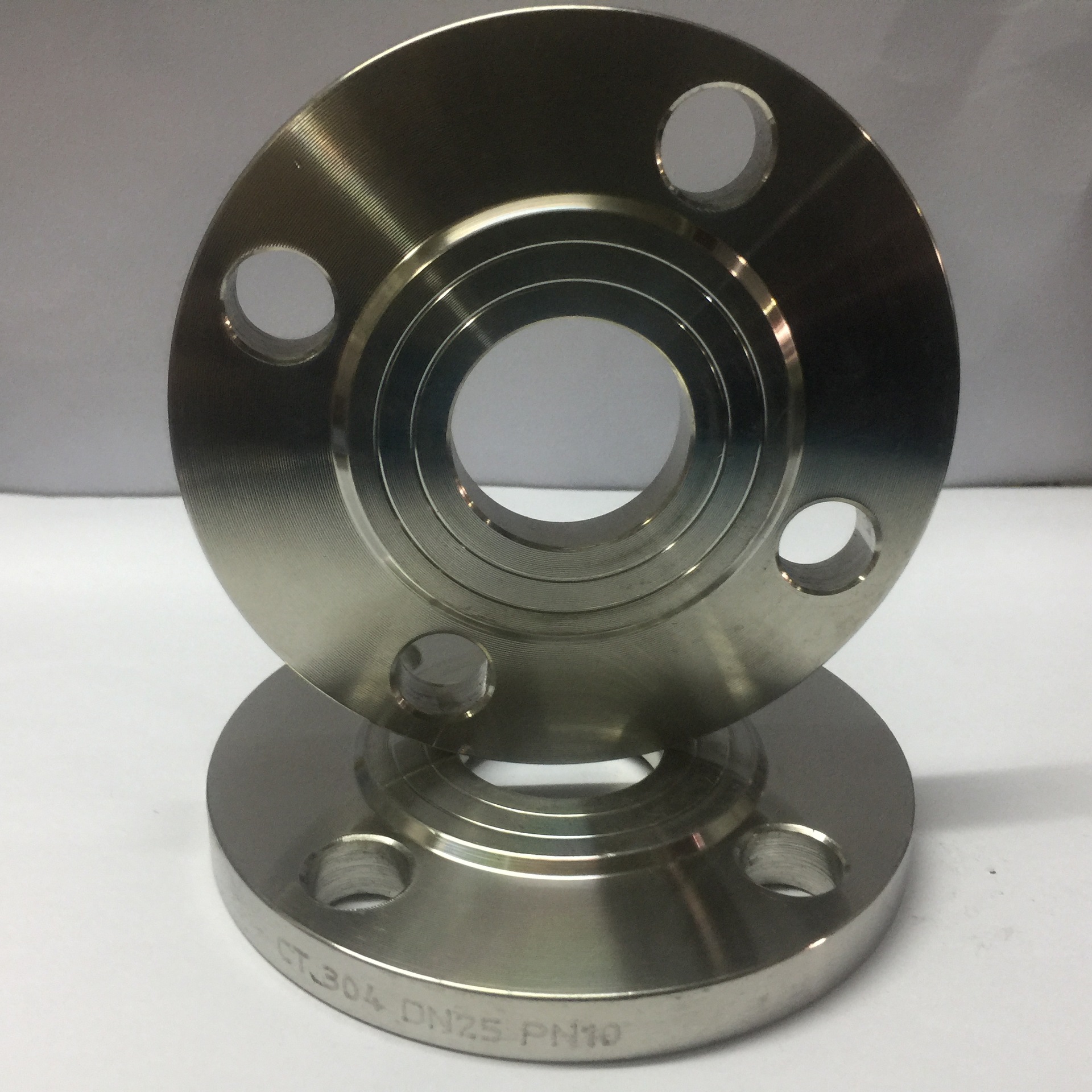

The 6% butterfly valve comprises a disc, a body, and a stem connected to the actuator. Various materials can be utilized for manufacturing these valves, such as stainless steel, cast iron, or plastic, depending on the application requirements. The seat material also plays a significant role, as it can impact the valve’s sealing capacity and durability.

The disc design is critical; a well-shaped disc reduces fluid turbulence, minimizing energy losses and enhancing efficiency. Furthermore, the 6% opening ensures that the fluid flow remains stable, preventing cavitation and erosion that often occur in larger openings.

6 butterfly valve

4. Applications

Due to its remarkable versatility, the 6% butterfly valve is widely used in different sectors. In the water and wastewater industry, these valves help manage flow rates in treatment plants and distribution systems. The oil and gas sector also employs 6% butterfly valves for controlling liquid hydrocarbons, ensuring safe and efficient transportation.

HVAC systems benefit significantly from these valves, where regulating airflow is essential for maintaining optimal temperature and humidity levels. The food and beverage industry uses butterfly valves to control the flow of various liquids, with strict adherence to sanitation and quality standards.

5. Advantages

The 6% butterfly valve offers several advantages

- Compact Design Its small footprint makes it suitable for tight spaces where larger valves would be impractical. - Quick Operation The quarter-turn mechanism allows for rapid opening and closing, enhancing operational efficiency. - Low Pressure Drop The streamlined design minimizes pressure loss, which is crucial in maintaining energy efficiency. - Cost-Effective Compared to other valve types, butterfly valves often have a lower initial cost and require less maintenance.

6. Conclusion

The 6% butterfly valve represents a crucial component in modern fluid control systems. Its unique ability to regulate flow effectively while maintaining a compact structure makes it indispensable across various industries. As technology advances and the demand for more efficient systems grows, butterfly valves, particularly the 6% variants, will continue to play a vital role in ensuring processes run smoothly and efficiently. Whether it’s for water treatment, oil transport, or HVAC applications, the 6% butterfly valve is a reliable and effective solution for maintaining optimal flow control.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025