Top Manufacturers of Vacuum Gate Valves for Industrial Applications and Solutions

The Importance of Vacuum Gate Valves in Industrial Applications

In the realm of industrial applications, vacuum gate valves play a crucial role in managing and controlling the flow of gases and fluids under vacuum conditions. These valves are essential instruments in various sectors, including chemical processing, pharmaceuticals, semiconductors, and food processing. As industries increasingly turn toward automation and advanced technologies, the demand for high-quality vacuum gate valves is rising, positioning manufacturers at the forefront of this essential equipment.

What are Vacuum Gate Valves?

Vacuum gate valves are specialized valves designed to function under vacuum conditions, allowing or restricting the flow of materials within pipelines. These valves are characterized by their ability to seal tightly when closed, preventing air or any non-desired elements from entering the system. They are typically constructed from durable materials that can withstand significant pressure differentials and chemical environments. The design of vacuum gate valves often includes features that enable them to maintain a vacuum seal effectively, which is critical in applications where contamination is a concern.

Key Features of Vacuum Gate Valves

1. Material Selection The choice of materials is pivotal in determining the performance of vacuum gate valves. Manufacturers typically utilize stainless steel, brass, or advanced alloys that exhibit resistance to corrosion, high temperatures, and wear. These materials ensure the longevity of the valves and maintain their integrity under challenging conditions.

2. Sealing Mechanisms The sealing mechanism is another vital aspect. Vacuum gate valves often employ soft seals made from elastomers or rigid seals designed to create a reliable barrier against leakage. The effectiveness of these seals is paramount to maintaining the necessary vacuum conditions.

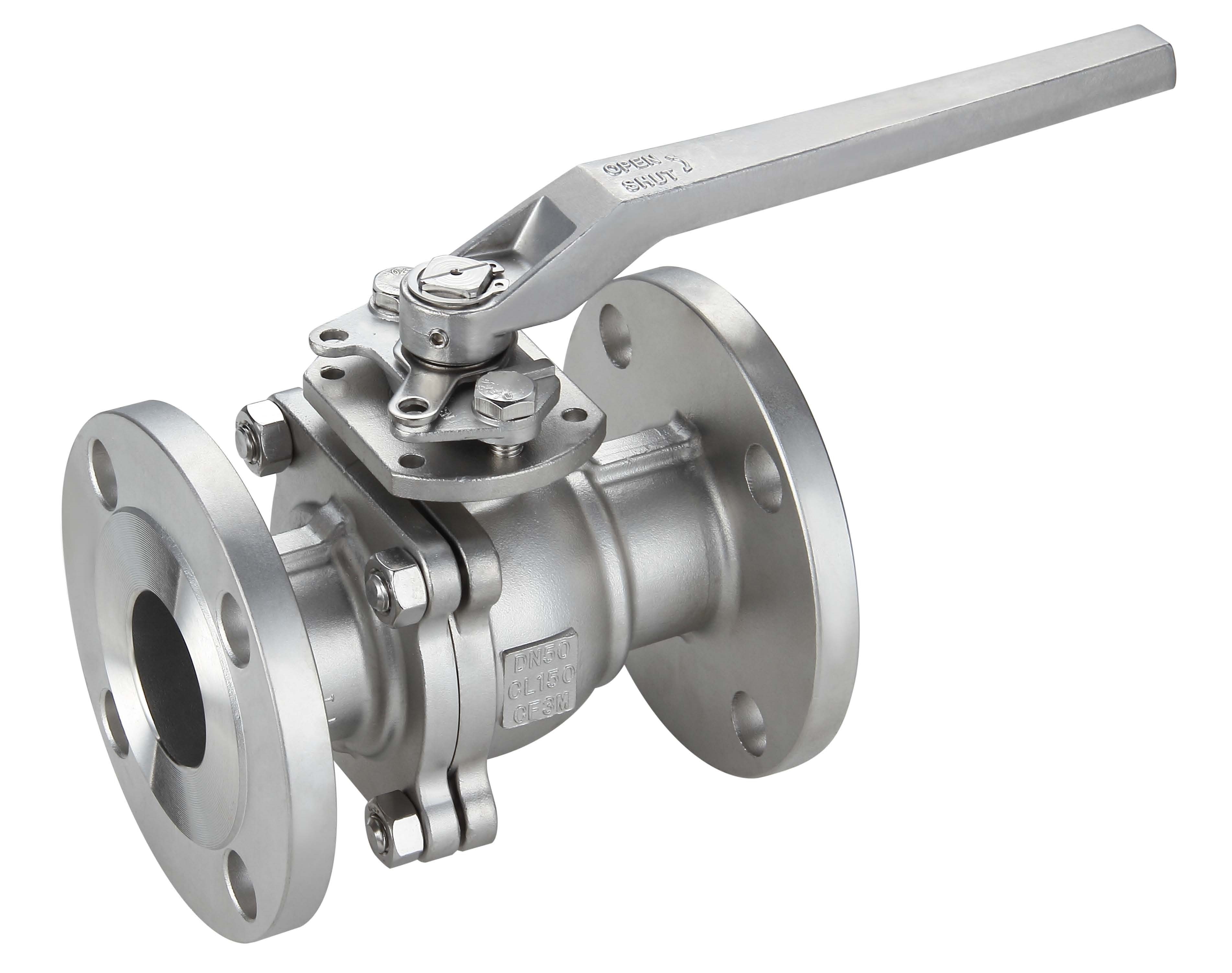

vacuum gate valves manufacturers

3. Automation Compatibility Many modern vacuum gate valves are designed to be compatible with automated systems. This integration facilitates precise control over operations, enhances efficiency, and reduces the risk of human error. Automation can significantly improve workflow processes, especially in high-volume production environments.

4. Versatile Designs Manufacturers offer a wide range of designs, including manual and pneumatic actuated valves. This versatility allows industries to select the appropriate valve that meets their specific operational requirements.

The Role of Manufacturers

As the demand for vacuum gate valves grows, several manufacturers have emerged, each striving to deliver products that meet stringent quality standards. The best manufacturers invest in research and development to improve valve designs, enhance material performance, and adopt the latest manufacturing technologies. They often engage in quality assurance practices that comply with international standards, ensuring that the valves not only perform reliably but are also safe for use in critical applications.

Moreover, leading manufacturers offer tailored solutions for their clients. This customization can involve creating valves with specific dimensions, pressure ratings, or material compositions based on the unique requirements of a project. Such flexibility is invaluable in industries where standard solutions may not suffice.

Conclusion

In conclusion, vacuum gate valves are indispensable in many industrial processes, ensuring the efficient and safe control of fluid and gas flow under vacuum conditions. With the increasing emphasis on automation and the need for high-quality products, the role of vacuum gate valve manufacturers has never been more significant. As industries continue to innovate, the demand for specialized, reliable vacuum gate valves will likely persist, pushing manufacturers to enhance their offerings continuously and adapt to emerging trends. The collaboration between manufacturers and end-users will ultimately drive the advancement of this crucial component in the broader landscape of industrial operations.

-

3-types-of-check-valves-maintenance-tipsNewsAug.23,2025

-

ball-valves-types-with-trunnion-mounted-designNewsAug.23,2025

-

butterfly-valve-company-production-capabilitiesNewsAug.23,2025

-

fisher-globe-valve-technical-specificationsNewsAug.23,2025

-

types-of-gaskets-for-flanges-selection-guideNewsAug.23,2025

-

wedge-gate-valve-suppliers-quality-standardsNewsAug.23,2025

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025