lugged type butterfly valve

The Lugged Type Butterfly Valve An Overview

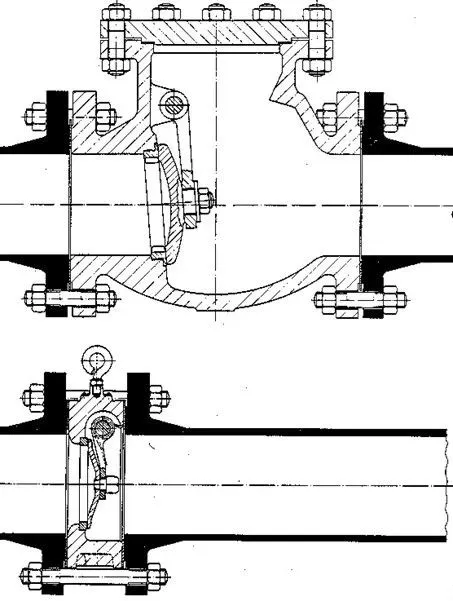

The lugged type butterfly valve is an essential component in many industrial applications, especially in systems requiring efficient flow control and minimal leakage. This valve design features lugs or protrusions on either side, allowing it to be mounted directly to a flange. This unique characteristic provides the flexibility to use the valve in various configurations, such as in a dead-end service situation, where the valve can be removed without disturbing the piping system.

Design and Features

The lugged butterfly valve operates using a circular disc that rotates around a central shaft. The disc is positioned in the flow path, and its rotation controls the flow of fluid through the valve. When turned to a perpendicular position, the valve is closed, while a parallel position allows for full flow. This simple yet effective mechanism provides excellent performance across a range of applications.

One of the distinct features of the lugged type butterfly valve is its design for easy disassembly. The lugs allow the valve to be bolted directly to the pipeline using standard flanges. This is particularly beneficial for maintenance and repairs, as technicians can remove the valve without having to dismantle adjacent pipework. It streamlines maintenance operations and reduces downtime, a critical factor in industries where continuous operation is vital.

Applications

Lugged type butterfly valves are widely used in various industries, including water treatment, chemical processing, HVAC systems, and oil and gas. In water treatment facilities, they help regulate water flow in treatment processes, ensuring optimal performance and compliance with environmental regulations. In chemical processing plants, these valves manage corrosive fluids and gases, making them essential for safety and efficiency.

lugged type butterfly valve

The oil and gas industry also relies on lugged butterfly valves for their robustness and reliability. They are used in pipelines to control the flow of crude oil and natural gas, where any leakage can have catastrophic environmental impacts. Their capability to isolate sections of a pipeline makes them ideal for maintenance scenarios, allowing for safety and efficiency.

Advantages

The lugged butterfly valve comes with several advantages. One of its significant benefits is its low-pressure drop across the valve, which contributes to energy efficiency in fluid handling systems. Additionally, the compact design saves space and allows for installation in tight areas that traditional valves might not fit.

Another advantage is the variety of materials available for manufacturing lugged butterfly valves, including cast iron, stainless steel, and plastic. This versatility enables users to select the best material for their specific application, whether it involves high temperatures, corrosive fluids, or standard water flow.

Conclusion

In conclusion, the lugged type butterfly valve is a valuable asset in industrial flow control systems. Its innovative design, characterized by its lugs for easy mounting and dismounting, allows for versatile applications in various industries. The combination of ease of maintenance, efficiency, and adaptability to different materials makes the lugged butterfly valve an indispensable component in modern piping systems. As industries continue to evolve, the demand for reliable flow control solutions like the lugged butterfly valve will undoubtedly grow, ensuring its place in the future of industrial applications.

-

The Versatility of Ball Valves in Fluid Control SystemsNewsJun.10,2025

-

The Practical Benefits of Centerline Butterfly ValvesNewsJun.10,2025

-

The Benefits of Bellows Seal Globe Valves for Industrial SystemsNewsJun.10,2025

-

The Advantages of Offset Butterfly ValvesNewsJun.10,2025

-

Ductile Gate Valves: Strong, Reliable, and Essential for Every SystemNewsJun.10,2025

-

Cast Iron Gate Valves: A Reliable Solution for Every SystemNewsJun.10,2025

-

Why Choose a Brass Gate Valve for Superior Performance and DurabilityNewsMay.09,2025