Feb . 18, 2025 01:55

Back to list

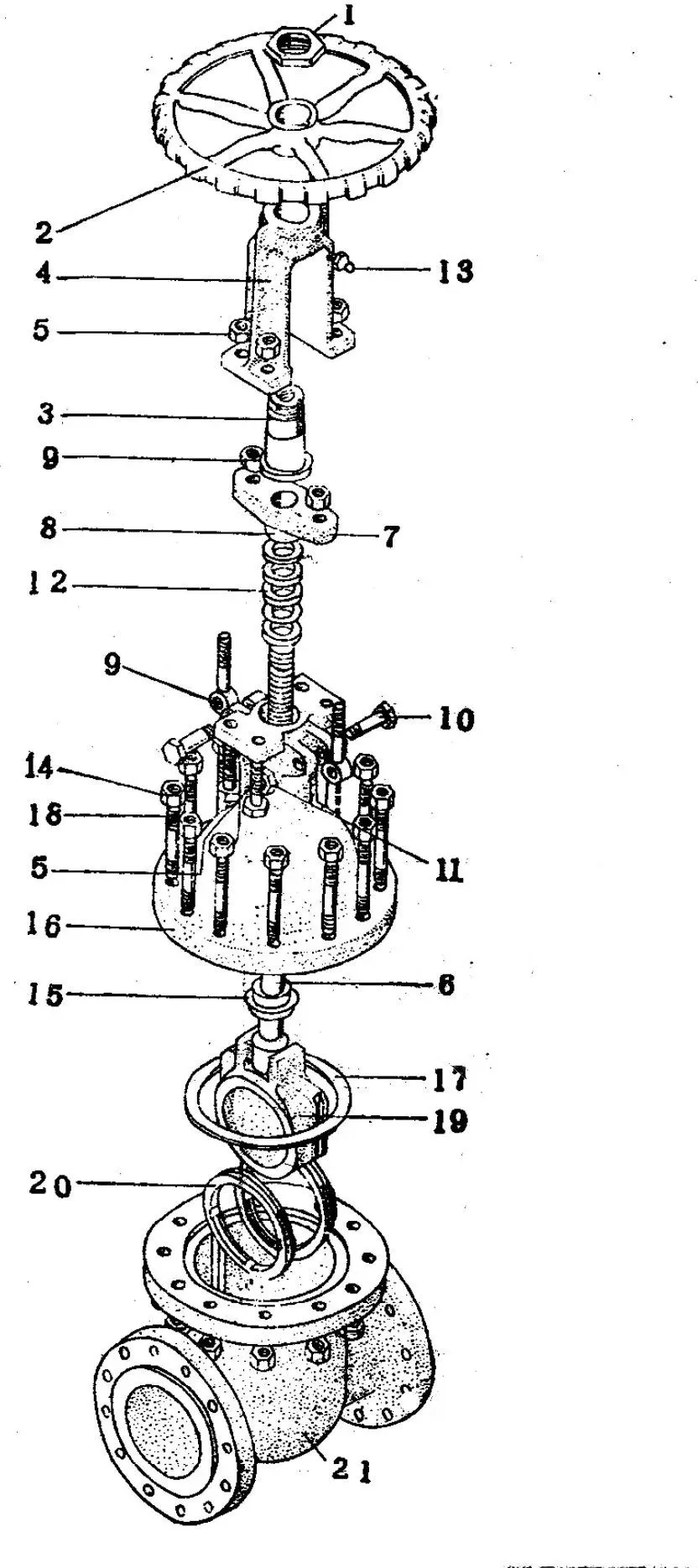

J23W stainless steel external thread needle valve

The China low pressure needle valve is crucial in many industries seeking precise control over fluid flow under low-pressure conditions. Its niche application highlights the need for understanding its intricacies to yield maximum operational efficiency. This article delves into the complexities of these valves and showcases their unique advantages, drawing on expertise from industry professionals to guide buyers in making informed decisions.

In-depth case studies reveal interesting insights into implementation success. A notable example is a chemical plant that faced chronic leakage issues with their existing valves, risking product contamination. By switching to a needle valve from a reputable Chinese manufacturer with a focus on precision engineering, the plant reported a drastic improvement in flow control and eliminated leakage, demonstrating the valve's reliability and performance superiority. Industry experts also point out the competitive pricing of these valves from China, offering cost savings without sacrificing quality. This combination of affordability and performance is largely attributed to rigorous quality control processes adhered to by leading manufacturers. Certifications such as ISO 90012015 underline their commitment to consistent production quality, providing customers with assurance of their investment. Engagement with industry veterans brings about recommendations for maintenance practices to prolong the life of low-pressure needle valves. Regular inspections, timely cleaning to prevent deposit buildup, and prompt replacement of worn-out components are foundational practices. Real-world accounts show that following these maintenance tips can extend valve lifespan by as much as 50%, solidifying the producer's claims of durability and performance longevity. Summarily, the China low pressure needle valve stands out as a vital component in industries requiring precision and reliability. Its blend of advanced engineering, cost-effectiveness, and customizable options makes it a trusted choice for professionals seeking excellence in fluid control under low pressure conditions. Given the breadth of real-world testimonials and expert endorsements, potential buyers can rest assured of making a wise selection that balances cost with high performance. This integration of knowledge from practical experiences and authoritative guidance ensures that stakeholders in different sectors can achieve enhanced operational capabilities and efficiency.

In-depth case studies reveal interesting insights into implementation success. A notable example is a chemical plant that faced chronic leakage issues with their existing valves, risking product contamination. By switching to a needle valve from a reputable Chinese manufacturer with a focus on precision engineering, the plant reported a drastic improvement in flow control and eliminated leakage, demonstrating the valve's reliability and performance superiority. Industry experts also point out the competitive pricing of these valves from China, offering cost savings without sacrificing quality. This combination of affordability and performance is largely attributed to rigorous quality control processes adhered to by leading manufacturers. Certifications such as ISO 90012015 underline their commitment to consistent production quality, providing customers with assurance of their investment. Engagement with industry veterans brings about recommendations for maintenance practices to prolong the life of low-pressure needle valves. Regular inspections, timely cleaning to prevent deposit buildup, and prompt replacement of worn-out components are foundational practices. Real-world accounts show that following these maintenance tips can extend valve lifespan by as much as 50%, solidifying the producer's claims of durability and performance longevity. Summarily, the China low pressure needle valve stands out as a vital component in industries requiring precision and reliability. Its blend of advanced engineering, cost-effectiveness, and customizable options makes it a trusted choice for professionals seeking excellence in fluid control under low pressure conditions. Given the breadth of real-world testimonials and expert endorsements, potential buyers can rest assured of making a wise selection that balances cost with high performance. This integration of knowledge from practical experiences and authoritative guidance ensures that stakeholders in different sectors can achieve enhanced operational capabilities and efficiency.

Latest news

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025