Feb . 07, 2025 01:36

Back to list

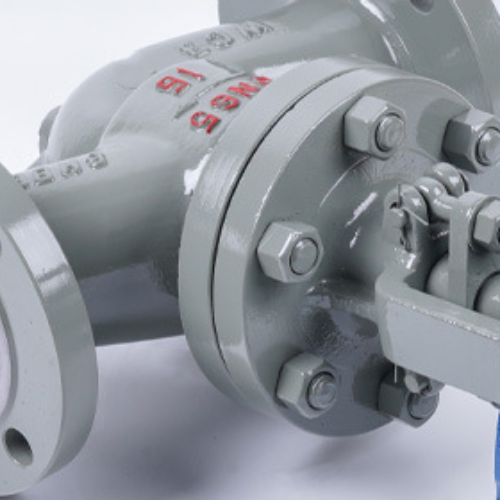

butterfly lug type valve

The butterfly lug type valve has emerged as an indispensable component in various industries, including chemical processing, water treatment, and food and beverage production. Renowned for its simplicity, efficiency, and robust construction, the butterfly lug type valve offers significant advantages that make it the ideal choice for controlling fluid flow in pipelines.

Industry authorities recognize the cost-effectiveness of the butterfly lug type valve, attributing significant savings to its use. Their lightweight design reduces the need for heavy support structures, while their compact size allows for installation in confined spaces where larger valves would be impractical. Additionally, maintenance costs are lowered as the valve components are easy to access and replace without requiring a complete system shutdown. This ease of maintenance coupled with durability ensures a lower total cost of ownership over the valve's lifecycle. Trust in the butterfly lug type valve's reliability is well-established, with testimonials from various industries confirming its consistent performance under rigorous conditions. Companies investing in these valves benefit not only from their technical attributes but also from enhanced safety due to their reliable sealing capabilities. This reliability minimizes the risk of fluid leakage, which can pose significant safety hazards, particularly in chemical or high-pressure systems. In terms of environmental sustainability, the butterfly lug type valve also scores high. Its efficient sealing minimizes fluid loss, thereby reducing waste and contributing to the sustainability goals of organizations. Further, materials such as stainless steel are recyclable, aligning with global recycling initiatives and companies' commitments to reduce their carbon footprint. Ultimately, the butterfly lug type valve stands out as a prime example of engineering excellence. Its blend of operational efficiency, cost-effectiveness, and adaptability across various applications makes it an essential component for modern industrial systems. For organizations seeking reliable flow control solutions, investing in this valve not only meets technical requirements but also aligns with broader goals of safety, sustainability, and economic efficiency.

Industry authorities recognize the cost-effectiveness of the butterfly lug type valve, attributing significant savings to its use. Their lightweight design reduces the need for heavy support structures, while their compact size allows for installation in confined spaces where larger valves would be impractical. Additionally, maintenance costs are lowered as the valve components are easy to access and replace without requiring a complete system shutdown. This ease of maintenance coupled with durability ensures a lower total cost of ownership over the valve's lifecycle. Trust in the butterfly lug type valve's reliability is well-established, with testimonials from various industries confirming its consistent performance under rigorous conditions. Companies investing in these valves benefit not only from their technical attributes but also from enhanced safety due to their reliable sealing capabilities. This reliability minimizes the risk of fluid leakage, which can pose significant safety hazards, particularly in chemical or high-pressure systems. In terms of environmental sustainability, the butterfly lug type valve also scores high. Its efficient sealing minimizes fluid loss, thereby reducing waste and contributing to the sustainability goals of organizations. Further, materials such as stainless steel are recyclable, aligning with global recycling initiatives and companies' commitments to reduce their carbon footprint. Ultimately, the butterfly lug type valve stands out as a prime example of engineering excellence. Its blend of operational efficiency, cost-effectiveness, and adaptability across various applications makes it an essential component for modern industrial systems. For organizations seeking reliable flow control solutions, investing in this valve not only meets technical requirements but also aligns with broader goals of safety, sustainability, and economic efficiency.

Latest news

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025