Leading Manufacturers of High-Quality Pneumatic Butterfly Valves for Efficient Fluid Control Solutions

The Role and Importance of Pneumatic Butterfly Valve Manufacturers

Pneumatic butterfly valves have become integral components in various industrial applications, known for their reliability, versatility, and efficiency. As a result, the role of pneumatic butterfly valve manufacturers plays a crucial part in ensuring that industries have access to high-quality and innovative solutions tailored to specific needs. This article explores the significance of these manufacturers in the broader context of industrial operations and the factors that drive their success.

Understanding Pneumatic Butterfly Valves

A pneumatic butterfly valve is a type of quarter-turn valve that uses a rotating disc to control the flow of fluid through a pipeline. When the valve is closed, the disc is perpendicular to the flow direction, preventing any fluid from passing. When opened, the disc is rotated parallel to the flow, enabling the fluid to flow freely. The pneumatic actuation mechanism offers fast response times and precise control, making it ideal for industries such as water treatment, chemical processing, food and beverage, and many others.

The Importance of Manufacturers

Pneumatic butterfly valve manufacturers are essential in the supply chain of industrial applications. They ensure that these valves are not only produced at scale but also adhere to rigorous standards for quality and safety. Here are several key reasons why the role of these manufacturers is vital

1. Innovation and Development The valve manufacturing industry is constantly evolving, with manufacturers investing in research and development to create more efficient, durable, and eco-friendly products. They are responsible for integrating the latest technologies and materials, such as corrosion-resistant alloys and advanced sealing methods, which enhance the performance and longevity of pneumatic butterfly valves.

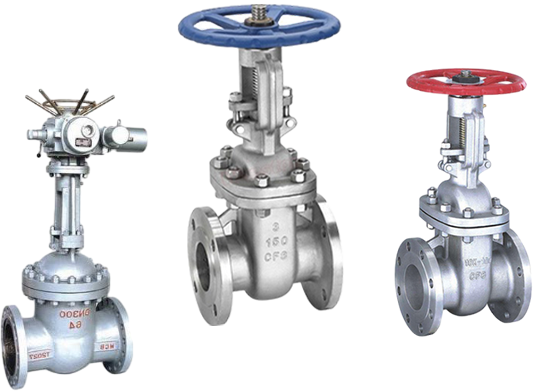

pneumatic butterfly valve manufacturer

2. Customization Different industries have unique needs, and manufacturers play a critical role in offering customized solutions. This can involve producing valves with specific dimensions, pressure ratings, and materials suited for particular environments and applications. Manufacturers who can provide tailored solutions are often more successful in meeting client demands.

3. Quality Assurance The reliability of pneumatic butterfly valves is paramount, as failures can lead to significant operational disruptions and safety hazards. Reputable manufacturers implement strict quality control measures, ensuring that every valve produced meets established industry standards and regulatory requirements. This emphasis on quality builds trust and credibility among clients.

4. Global Reach and Supply Chain Management Many manufacturers operate on a global scale, allowing them to source materials and distribute their products worldwide. This capability is especially important in today's interconnected economy, where sourcing components from different regions can lead to cost savings and enhanced product availability.

5. Technical Support and Service Beyond manufacturing, many companies offer technical support and service to their customers. This includes assistance with valve selection, installation, maintenance, and troubleshooting, helping clients optimize their operations and minimize downtime.

Conclusion

Pneumatic butterfly valve manufacturers are pivotal players in the industrial landscape, providing essential products and services that drive efficiency and safety across various sectors. Their commitment to innovation, customization, and quality assurance ensures that industries can rely on them for their fluid control needs. As technology advances and industries continue to evolve, these manufacturers will undoubtedly adapt and expand their offerings, further solidifying their critical role in global supply chains. As stakeholders in various sectors, it is crucial to recognize the importance of partnering with reputable manufacturers who understand the complexities of the markets they serve.

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025