2 pipe fittings

Understanding 2% Pipe Fittings A Critical Component in Fluid Transport Systems

In the world of engineering and construction, effective fluid transport systems are essential for various applications, ranging from residential plumbing to industrial processes. Among the myriad components that facilitate these systems, pipe fittings play a crucial role. In particular, the phrase 2% pipe fittings often references a specific tolerance level that engineers and designers consider when selecting fittings for different projects. This article aims to explore the significance of 2% pipe fittings, their applications, and why precision matters in fluid dynamics.

What are Pipe Fittings?

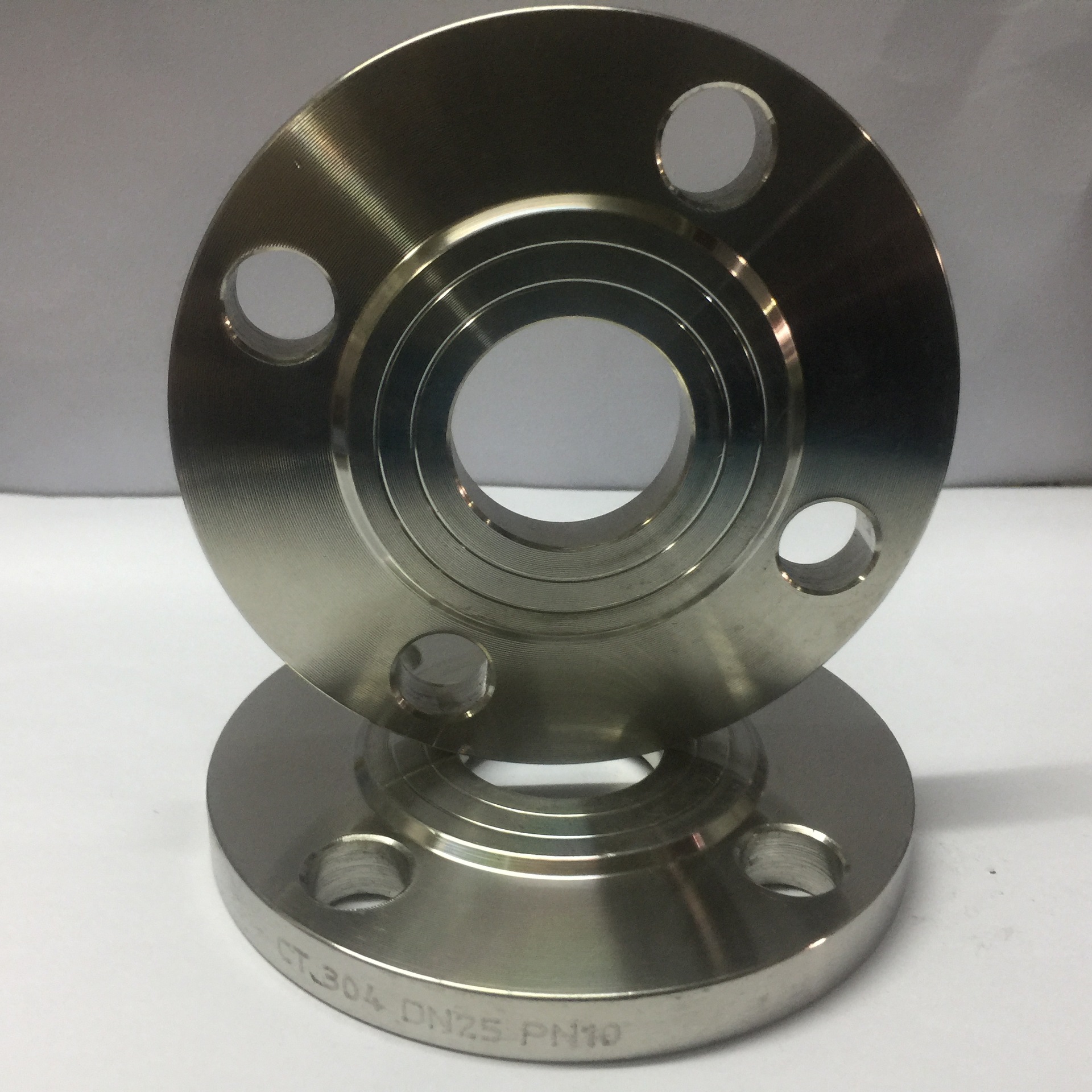

Pipe fittings are attachments that connect, terminate, or change the direction of pipes in a fluid transport system. These fittings come in various shapes and sizes, including elbows, tees, couplings, and flanges. Their primary function is to ensure seamless connectivity in piping systems, allowing fluids to flow smoothly and safely. The materials used for pipe fittings can vary widely, including metals like stainless steel and brass, as well as plastics such as PVC and polyethylene.

The Importance of Specification Understanding the 2% Tolerance

The term 2% pipe fittings refers to the allowable deviation or tolerance in dimensions that contribute to the overall accuracy of construction and installation. In engineering, a 2% tolerance means that the actual dimensions of the fittings can differ by up to 2% from the specified dimensions without affecting the performance of the piping system significantly. This tolerance level is crucial, especially when working with systems that demand high precision, such as chemical processing plants or food and beverage manufacturing facilities.

Applications of 2% Pipe Fittings

1. Engineering and Construction From the initial design phase to the final installation, 2% pipe fittings are integral to ensuring the desired flow rates and pressure controls in piping systems. Engineers must consider these tolerances when designing systems to ensure that the fittings will work as intended under various operational conditions.

2 pipe fittings

2. Oil and Gas Industry The oil and gas sector heavily relies on high-pressure piping systems, where even minor deviations in fitting dimensions can lead to catastrophic failures. The 2% tolerance level allows engineers to design reliable systems that can withstand extreme pressures and temperatures.

3. Water Supply Systems Municipal water supply systems utilize a variety of fittings to transport water. Here, precision is vital to avoid leaks and ensure that all connections maintain structural integrity over time. 2% pipe fittings ensure that all components work together seamlessly, minimizing the risk of water loss.

4. HVAC In heating, ventilation, and air conditioning systems, airflow and pressure regulation are crucial. The incorporation of 2% pipe fittings allows for optimized airflow, reducing energy consumption and improving overall system efficiency.

Why Precision Matters

Considering and implementing a 2% tolerance in pipe fittings can significantly impact various factors - Safety In applications where pressurized systems are involved, failures due to improper fitting dimensions can lead to accidents, injuries, or even fatalities. - Efficiency Systems designed with the correct tolerances typically operate more efficiently, saving resources and reducing operational costs. - Longevity Ensuring that pipes and fittings fit together correctly minimizes wear over time, extending the lifespan of the infrastructure.

Conclusion

In summary, 2% pipe fittings are a fundamental aspect of designing and constructing reliable fluid transport systems across various industries. Their specified tolerances ensure that engineers can design systems that will operate safely and efficiently under varying conditions. As technology advances and industries evolve, the importance of precision tolerances like the 2% fitting standard will only grow, emphasizing the essential role of these fittings in enhanced performance and reliability in fluid transport systems. Understanding and applying these specifications is key for engineers, designers, and builders in creating effective and sustainable infrastructure.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025