long stem ball valve

Understanding Long Stem Ball Valves

Long stem ball valves are essential components in various industrial applications, known for their reliability and efficient flow control. These valves are designed to regulate and shut off the flow of liquids or gases in pipelines. The unique feature of a long stem allows for easy operation, often making them suitable for hard-to-reach or elevated installations.

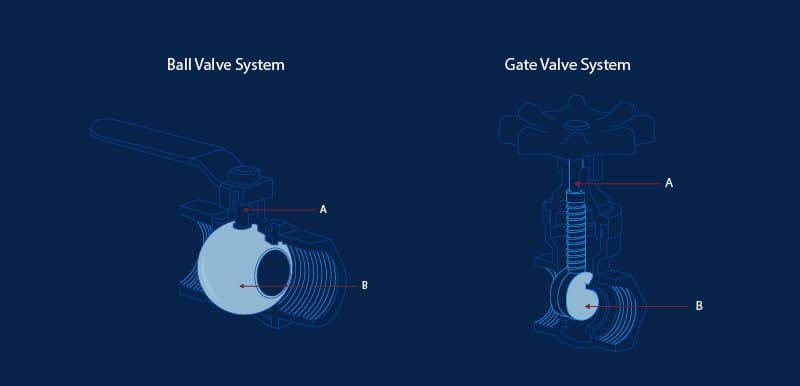

The structure of a long stem ball valve includes a spherical disc (the ball) that sits inside the valve body. When the valve is opened, the ball rotates to align the hole inside it with the pipeline, allowing fluid to flow through. Conversely, turning the valve handle to a closed position rotates the ball, blocking the passage and halting flow. This design provides a tight seal, minimizing the risk of leaks and ensuring safety in operations.

One of the primary advantages of long stem ball valves is their versatility. They can be used in a wide range of applications, from water supply systems and heating installations to chemical transport and oil refineries. Their robust design can withstand high pressure and temperature, making them suitable for demanding environments.

long stem ball valve

Another significant benefit of these valves is their ease of maintenance. The long stem allows operators to access and operate the valve from a distance, which is particularly useful in hazardous settings. Maintenance can often be performed without the need for extensive disassembly, leading to reduced downtime and operational efficiency.

In the context of industry standards, long stem ball valves are available in various materials, such as stainless steel, brass, and plastic. This adaptability ensures compatibility with different media, including corrosive substances. Furthermore, manufacturers often provide customization options, allowing users to specify sizes, pressure ratings, and operating mechanisms that match their unique specifications.

However, like any mechanical device, long stem ball valves require proper installation and care. Regular inspections are key to identifying any wear or damage that could affect performance. Operators should also be mindful of the valve's operating limits, as exceeding these can lead to failure and costly repairs.

In conclusion, long stem ball valves are a critical part of numerous industrial systems, offering reliability, efficiency, and ease of maintenance. Their design allows for safe operation in challenging environments, making them a preferred choice for engineers and operators alike. As industries continue to evolve, the role of long stem ball valves in ensuring safe and effective flow control will remain vital.

-

3-types-of-check-valves-maintenance-tipsNewsAug.23,2025

-

ball-valves-types-with-trunnion-mounted-designNewsAug.23,2025

-

butterfly-valve-company-production-capabilitiesNewsAug.23,2025

-

fisher-globe-valve-technical-specificationsNewsAug.23,2025

-

types-of-gaskets-for-flanges-selection-guideNewsAug.23,2025

-

wedge-gate-valve-suppliers-quality-standardsNewsAug.23,2025

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025