High-Quality 1 2 Stainless Steel Needle Valve | Precision Control Solutions

Understanding 1% 202 Stainless Steel Needle Valves

Needle valves are essential components in various industries, primarily used to control fluid flow with precision. Among the several materials used for these valves, 1% 202 stainless steel stands out due to its excellent combination of properties. The designation 1% 202 refers to the specific composition of the stainless steel, which includes a modest percentage of nickel and chromium, enhancing its strength and corrosion resistance.

Composition and Benefits

The primary characteristics of 202 stainless steel include good mechanical properties and improved resistance to corrosion. This alloy typically contains approximately 17% chromium, 4% nickel, and 1% manganese, which provide enhanced durability compared to other stainless steel grades. The inclusion of nickel aids in toughening the material, while chromium forms a protective passive layer that helps resist oxidation and rust.

Due to these properties, 1% 202 stainless steel needle valves are popular in various applications, including water treatment plants, petrochemical industries, and food processing. The ability to withstand high pressure and temperature makes them suitable for regulating flow in harsh environments. Furthermore, this type of stainless steel is often more cost-effective than higher-nickel grades, making it a practical choice for many manufacturers.

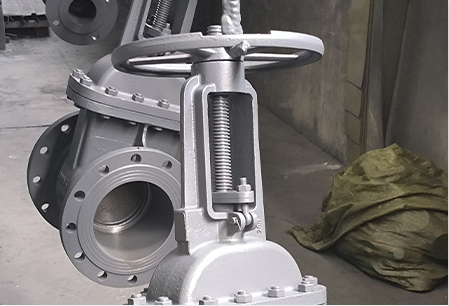

1 2 stainless steel needle valve

Applications of Needle Valves

Needle valves are primarily used for throttling and fine control of flow. The design of these valves, with a long, tapered point, enables precise adjustments to manage flow rates effectively. Industries that rely on these valves include oil and gas, where they control the flow of crude oil and various chemicals, and HVAC systems, where they help regulate heating and cooling systems. Additionally, they are widely used in laboratories and research facilities, where precise control of liquid or gas flow is necessary.

Maintenance and Durability

One of the noteworthy advantages of 1% 202 stainless steel needle valves is their low maintenance requirement. The corrosion-resistant properties mean that these valves can maintain their integrity over time even in aggressive environments. Routine checks are still essential to ensure that seals and other components function correctly, but overall, these valves are built for longevity.

In conclusion, 1% 202 stainless steel needle valves offer a perfect blend of affordability, durability, and performance. Their ability to handle various fluids and gases while providing precise control makes them invaluable in many industrial applications. As industries continue to seek efficient and reliable flow control solutions, the demand for 1% 202 stainless steel needle valves will likely remain strong.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025