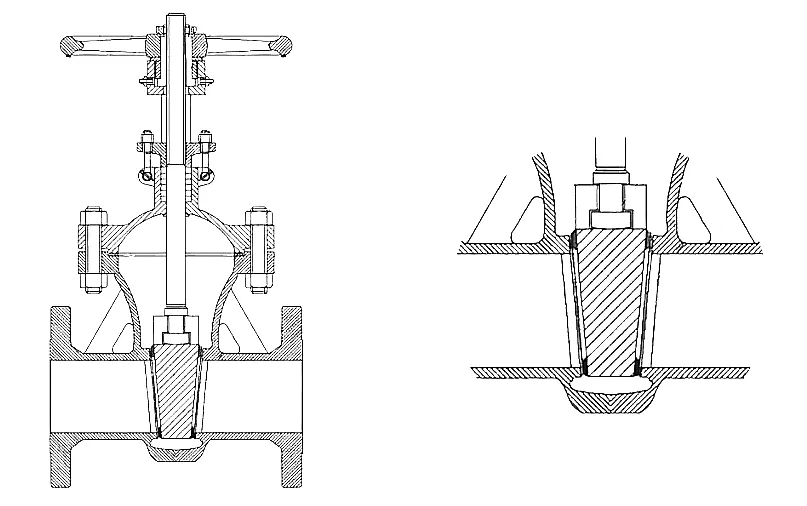

1 2 316 stainless steel ball valve

The Advantages of 1% 202 316 Stainless Steel Ball Valves

Stainless steel ball valves, particularly those made from 1% 202 and 316 stainless steel, play an essential role in various industrial applications, from oil and gas to water treatment. These valves are designed to provide reliable operation and maintain fluid control with minimal resistance. Understanding their characteristics, benefits, and applications offers insights into why they are favored in many industries.

Composition and Properties

1% 202 and 316 stainless steel are specific alloys that enhance the performance of ball valves. The 202 grade offers good corrosion resistance and strength, making it suitable for moderate-duty applications. However, the 316 grade is often considered the premium choice due to its superior corrosion resistance and durability. This grade includes molybdenum, which provides a higher tolerance to chlorides and acidic environments. These properties make 316 stainless steel ball valves particularly effective in harsh conditions, such as marine environments or chemical processing plants.

Benefits of Using 316 Stainless Steel Ball Valves

1. Corrosion Resistance One of the most significant benefits of using 316 stainless steel is its high resistance to corrosion. This feature is critical for applications where the valve is exposed to hostile media, such as seawater or aggressive chemicals.

2. Durability These ball valves are designed to endure high pressure and temperature extremes. They can handle various fluids and gases, ensuring long-term reliability and reduced maintenance costs.

3. Versatility 316 stainless steel ball valves are versatile and can be used in a wide range of industries, including pharmaceuticals, food processing, petrochemicals, and HVAC systems. Their adaptability to different applications makes them a preferred choice among engineers and procurement teams.

1 2 316 stainless steel ball valve

4. Low Flow Resistance The design of ball valves allows for minimal flow restriction when fully open, enabling efficient fluid control. This characteristic is particularly beneficial in systems where maintaining flow rates is crucial.

5. Ease of Maintenance These valves are designed to be user-friendly. Most ball valves can be easily disassembled and reassembled for maintenance without requiring specialized tools, making routine checks straightforward.

Application Areas

The application of 1% 202 and 316 stainless steel ball valves spans various sectors

- Oil and Gas In this sector, the durability and corrosion resistance of 316 stainless steel ensure that valves perform effectively, even in challenging environments. - Water Treatment The robust nature of these valves makes them ideal for controlling water flow in treatment facilities, providing essential reliability in critical processes.

- Food and Beverage The hygienic properties of 316 stainless steel make it suitable for food processing applications, where sanitation and compliance with health standards are paramount.

Conclusion

In conclusion, the use of 1% 202 and 316 stainless steel ball valves is essential for ensuring efficient and reliable fluid control across a vast array of industries. Their corrosion resistance, durability, versatility, and low maintenance requirements make them an invaluable component in many systems. Whether in a chemical plant, a water treatment facility, or a food processing line, these ball valves continue to prove their worth, meeting demanding industry standards and contributing to operational efficiency. Their ongoing popularity underscores the importance of choosing the right materials and designs in today’s industrial landscape.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025