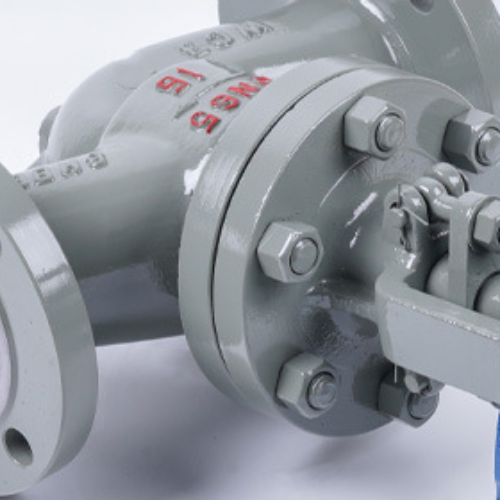

1 inch compact ball valve for efficient fluid control applications

Understanding the 1% 202% Inch Mini Ball Valve An Essential Component in Fluid Control

In industrial and domestic applications alike, the importance of effective fluid control cannot be overstated. At the heart of many fluid systems lies a plethora of components designed to regulate the flow of liquids and gases. Among these components, the mini ball valve stands out for its simplicity, reliability, and versatility. In this article, we will delve into the specifics of the 1% 202% inch mini ball valve, exploring its construction, functionality, applications, and maintenance considerations.

What is a Mini Ball Valve?

A mini ball valve is a type of valve that uses a spherical disk (the ball) to control the flow of fluids. When the valve is turned, the hole in the ball aligns with the pipe, allowing fluid to flow; when the valve is closed, the ball turns, blocking the flow. This straightforward mechanism provides rapid on-off control, which is particularly beneficial in applications where quick shutdown is necessary.

The designation 1% 202% inch refers to the dimensions and specifications of the valve, indicating it falls within specific standards of mini ball valves. These valves are compact, making them suitable for applications where space is limited.

Key Features

1. Compact Design The compact nature of mini ball valves allows them to fit snugly into installations where traditional valves would be too large or cumbersome. This makes them perfect for use in tight plumbing spaces, machinery, and portable systems.

2. Versatile Materials Mini ball valves can be constructed from various materials, including brass, stainless steel, and PVC. Each material type offers unique advantages, such as corrosion resistance in harsh environments or cost-effectiveness for less demanding applications.

3. Ease of Operation The simple quarter-turn operation of ball valves means that anyone can effectively use them with minimal training. This feature is particularly valuable in situations where rapid adjustments may be necessary.

4. Reliability Ball valves are known for their longevity and ability to maintain a tight seal, even under high pressure. This reliability is crucial in preventing leaks and ensuring the safety and efficiency of fluid systems.

Applications

The 1% 202% inch mini ball valve is utilized across various industries due to its adaptability

. Some of the most common applications include1 2 inch mini ball valve

- Plumbing and HVAC Systems In residential and commercial plumbing, mini ball valves are frequently used to control water flow. Their small size enables their use in areas with limited space.

- Agricultural Systems Farmers often rely on mini ball valves for irrigation systems, allowing for precise control of water distribution across fields.

- Automotive Applications In vehicles, these valves are often employed in cooling and fuel systems to regulate flow and ensure optimal engine performance.

- Manufacturing and Chemical Processing In industrial settings, mini ball valves are used to manage the flow of various liquids and gases, contributing to safe and efficient operations.

Maintenance Tips

Maintaining a mini ball valve is crucial for ensuring its long-term performance. Here are some essential maintenance tips

1. Regular Inspections Periodically check the valve for any signs of wear, corrosion, or leaks. Early detection can prevent more significant issues down the line.

2. Lubrication Depending on the environment and frequency of use, it may be necessary to lubricate the valve components to ensure smooth operation, particularly for valves exposed to outdoor elements.

3. Cleanliness Keep the area around the valve clean and free of debris. Accumulated dirt can interfere with the valve's operation and lead to malfunctions.

4. Prompt Repairs If any issues are detected during inspections, address them promptly. This can include replacing seals or gaskets to maintain an effective seal.

In conclusion, the 1% 202% inch mini ball valve plays a critical role in fluid control systems across numerous industries. Its compact design, ease of use, and reliability make it an invaluable component in various applications. By understanding its features, advantages, and maintenance requirements, users can ensure optimal performance and longevity of this essential device. Whether in plumbing, agriculture, or industrial processes, mini ball valves continue to exemplify the principles of functionality and efficiency in fluid control.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025