1 2 threaded valve

Understanding the 1% 202% Threaded Valve Features and Applications

Valves play a crucial role in various industries by controlling the flow of liquids and gases. Among the different types of valves, the threaded valve stands out due to its versatility and ease of installation. In this article, we will delve into the concept of the 1% 202% threaded valve, exploring its features, benefits, and typical applications.

What is a Threaded Valve?

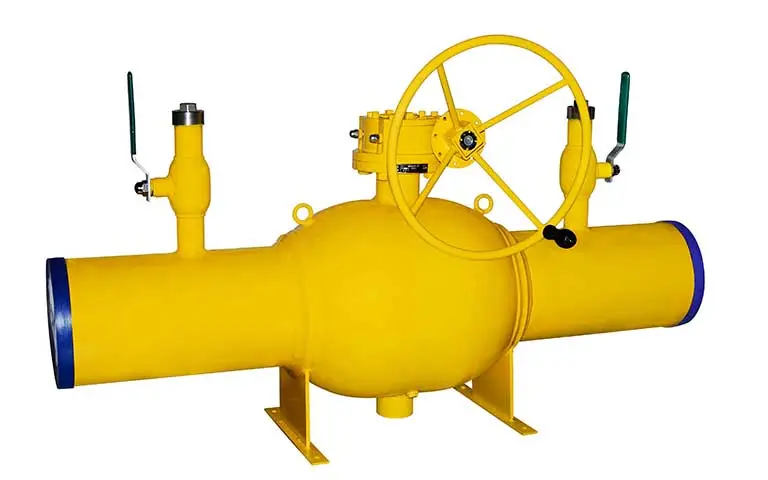

A threaded valve is a type of valve that utilizes threads to establish connections between pipes. This threaded configuration allows for easy installation and removal, making maintenance and replacement straightforward. Threaded valves are commonly available in various configurations, including ball valves, gate valves, and globe valves. The specific designation of 1% 202% could refer to a particular model or specification standard within a niche, indicating performance metrics, pressure ratings, or industry compliance.

Features of the 1% 202% Threaded Valve

1. Durability Threaded valves like the 1% 202% model are typically constructed from high-quality materials such as brass, stainless steel, or PVC. These materials provide excellent corrosion resistance and can withstand harsh operating conditions.

2. Pressure Rating The 202% might refer to the valve's ability to handle a specific pressure range. Understanding the pressure rating is essential for ensuring the valve operates efficiently without risk of failure or leakage.

3. Connection Compatibility The threaded nature of the valve ensures compatibility with a wide range of piping sizes and materials. This feature broadens its usability across various applications in different industries.

4. Fluid Control Precision Valves such as the 1% 202% are designed to provide precise control over fluid flow. This capability is vital in processes where maintaining specific flow rates and pressures is critical.

5. Ease of Operation Many threaded valves come with user-friendly handles or actuators, making them easy to operate, even in high-pressure scenarios.

Advantages of Using Threaded Valves

1. Installation Simplicity Threaded valves can be installed quickly without the need for specialized tools or expertise, reducing labor costs and installation time.

1 2 threaded valve

2. Maintenance and Repair The ability to easily remove and replace threaded valves simplifies maintenance procedures. This is particularly valuable in systems requiring regular inspections or updates.

3. Versatile Applications Due to their compatibility with various fluids — including water, chemicals, and gases — threaded valves find applications in numerous industries, from agriculture to pharmaceuticals.

Applications of the 1% 202% Threaded Valve

1. Water Supply Systems In municipal and industrial water systems, threaded valves are widely used to regulate flow and isolate sections of piping for maintenance.

2. Oil and Gas In the oil and gas industry, critical operations rely on robust fluid control methods, making threaded valves essential for managing the flow of hydrocarbons.

3. Chemical Processing Industries that deal with corrosive chemicals depend on high-quality threaded valves to ensure safe and efficient handling of hazardous materials.

4. HVAC Systems Threaded valves are integral components in heating, ventilation, and air conditioning systems, where they help maintain temperature and airflow.

5. Manufacturing and Production Many manufacturing processes involve fluids that need precise control, making threaded valves key components in production lines.

Conclusion

The 1% 202% threaded valve exemplifies the integral role valves play in fluid management across various industries. With their robust design, easy installation, and versatility, these valves ensure that fluids are transported safely and efficiently. Whether managing water flow, handling chemicals, or maintaining gas systems, the threaded valve remains a cornerstone of operational effectiveness. Understanding their features and applications is essential for engineers and professionals tasked with designing and maintaining efficient fluid control systems. As technology advances and industries evolve, threaded valves will continue to adapt, ensuring they remain a vital component in modern infrastructure.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025