Exploring the Functionality and Applications of 1% 204% Check Valve Systems

Understanding the 1% to 4% Check Valve A Comprehensive Overview

Check valves are essential components in various fluid systems, ensuring that the flow of fluids is controlled and that backflow is prevented. Among the different types of check valves, the 1% to 4% check valve has gained attention for its specific applications and advantages. This article aims to delve into the characteristics, functioning, and applications of the 1% to 4% check valve, offering insight into its operational mechanisms and benefits.

What is a Check Valve?

A check valve, also known as a non-return valve, is designed to allow fluid to flow in one direction while preventing it from flowing back. This is crucial in many systems where backflow could cause contamination, damage, or inefficient operation. Check valves come in various types, including swing, lift, ball, and diaphragm check valves, each suitable for different operational environments and fluid types.

The 1% to 4% Check Valve Explained

The term 1% to 4% check valve specifically refers to a valve designed to manage a certain range of flow rates or pressure differentials. This specification often indicates the valve's operational efficiency, pressure range, or the proportion of the inlet pressure that can be redirected or restricted. Typically, in applications that require precision control over the pressure or flow rate, valves that operate effectively within this percentage range are utilized.

Operation Principles

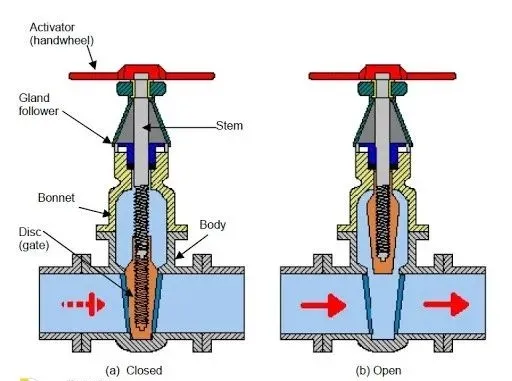

The 1% to 4% check valve functions on a simple yet effective principle of pressure differences. When the fluid moves through the valve, the pressure generated by the fluid flow pushes the valve disc or ball open, allowing the fluid to pass through. When there is a decrease in pressure on the downstream side, the valve closes under the influence of either gravity or a spring mechanism, thus preventing backflow.

The key to the 1% to 4% specification lies in its ability to maintain optimal flow conditions with minimal leakage or pressure loss. This is particularly important in systems such as water supply lines, sewage treatment plants, and chemical processing operations, where even slight backflow can have adverse effects.

Applications

The 1% to 4% check valve is commonly found in a variety of applications, including

1 4 check valve

1. Water and Wastewater Treatment These check valves are crucial in preventing backflow in treatment systems, ensuring that treated water does not mix with untreated waste.

2. Chemical Processing In industries where chemicals are handled, maintaining the integrity of the flow is vital. The 1% to 4% check valve helps regulate flow and prevent the contamination of products due to backflow.

3. HVAC Systems In heating, ventilation, and air conditioning systems, these valves are used to maintain pressure differences, ensuring efficient operation and preventing backflow that may disrupt airflow or temperature control.

4. Fire Protection Systems In fire suppression systems, check valves are essential to ensure that water flows in only one direction, providing reliable access to firefighting resources without the risk of backflow.

Benefits of the 1% to 4% Check Valve

1. Reliability Designed to operate under varying conditions, these check valves provide a dependable solution for preventing backflow.

2. Efficiency By maintaining optimal flow and reducing the chances of leakage, they contribute to the overall efficiency of fluid systems.

3. Versatility The 1% to 4% check valve can be used in various applications, making it a versatile component for engineers and designers.

4. Ease of Maintenance Many modern check valves are designed for easy maintenance, ensuring that they can be serviced without significant downtime.

Conclusion

In conclusion, the 1% to 4% check valve is a critical component in numerous fluid systems, offering precise control over flow direction and ensuring reliability in applications ranging from water treatment to industrial processing. Understanding the workings and benefits of this specific type of check valve empowers engineers and technicians to make informed decisions when designing and maintaining fluid systems. As industries continue to evolve, the importance of effective flow management solutions like the 1% to 4% check valve will undoubtedly remain a key focus for ensuring operational efficiency and safety.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025