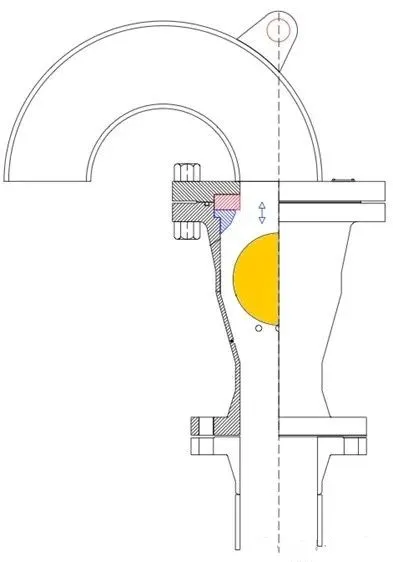

1.5 inch stainless steel ball valve

Understanding the 1.5% Stainless Steel Ball Valve A Key Component in Fluid Control Systems

In the realm of industrial applications and fluid control systems, valves play a crucial role in regulating the flow of liquids and gases. Among the various types of valves, the 1.5-inch stainless steel ball valve stands out as a preferred choice for many engineers and system designers due to its robustness, reliability, and versatility.

What Is a Ball Valve?

A ball valve is a type of quarter-turn valve that uses a hollow, perforated, and pivoting ball to control flow. The ball is positioned within the valve body and, depending on its orientation, can either allow or restrict the flow of the fluid. When the ball is rotated 90 degrees, the flow path is either opened or closed, which makes the ball valve an efficient tool for quick shut-off and precise flow control.

Stainless Steel as a Material of Choice

The choice of stainless steel as the material for these ball valves is significantly influenced by its excellent properties. Stainless steel is known for its corrosion resistance, strength, and durability, making it suitable for a wide range of applications, particularly in industries that deal with harsh environments, such as pharmaceuticals, petrochemicals, food processing, and water treatment.

The 1.5-inch size designation refers to the nominal pipe diameter the valve is designed to fit with. This size strikes a balance between being manageable for installation and capable of handling significant flow rates.

Features and Benefits

1. Durability Stainless steel ball valves are designed for longevity. They can withstand high pressure and fluctuating temperatures, ensuring reliable operation even under adverse conditions.

1.5 inch stainless steel ball valve

2. Corrosion Resistance Due to the inherent properties of stainless steel, these valves exhibit exceptional resistance to rust and corrosion. This makes them ideal for use in environments where they may come into contact with aggressive chemicals or moisture.

3. Quick Operation The quarter-turn mechanism of ball valves allows for rapid opening and closing. This is essential in applications where time is critical and fast fluid control is necessary.

4. Minimal Pressure Drop The design of the ball valve ensures that there is minimal pressure drop when the valve is open. This efficiency is crucial in maintaining system performance and integrity.

5. Ease of Maintenance Stainless steel ball valves are relatively easy to maintain. Their simple design allows for easy disassembly and cleaning, which is vital in hygiene-sensitive applications.

Applications of 1.5-Inch Stainless Steel Ball Valves

The versatility of the 1.5-inch stainless steel ball valve allows it to be used across various sectors

- Water and Wastewater Treatment Here, the valve is used to control the flow of water in treatment facilities, ensuring efficient management of resources. - Food and Beverage Industry The valve’s sanitary design and corrosion resistance make it suitable for transporting food and beverage products, adhering to health standards. - Oil and Gas In this sector, these valves are utilized to control the flow of hydrocarbons under high-pressure conditions. - Chemical Processing Their ability to handle aggressive chemicals makes them invaluable in chemical manufacturing environments.

Conclusion

In summary, the 1.5-inch stainless steel ball valve is a pivotal component in various fluid control systems. Its combination of durability, corrosion resistance, and operational efficiency makes it a reliable choice for industries ranging from food and beverage to chemical processing. Whether for new system designs or maintenance of existing operations, the adoption of stainless steel ball valves continues to play a significant role in enhancing overall system performance and safety. As industries evolve and seek more efficient, durable materials, the importance of high-quality components like the stainless steel ball valve will only continue to grow.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025