Understanding the Functionality of a 2% Ball Float Valve in Liquid Systems

Understanding the 2% Ball Float Valve A Comprehensive Overview

In industrial and mechanical applications, fluid management is a critical component for operational efficiency and safety. One of the essential devices that aid in such management is the ball float valve. Among the various types, the 2% ball float valve has gained prominence due to its unique characteristics and benefits. This article will explore the design, functionality, application, and advantages of the 2% ball float valve, providing a thorough understanding of this essential component.

What is a Ball Float Valve?

A ball float valve is a type of valve that automatically regulates the flow of liquid in tanks, ponds, and other water systems. It works based on buoyancy—when the liquid level rises, it pushes the float upward, and when the liquid level falls, the float sinks. The movement of the float is connected to the valve mechanism, opening or closing the flow in response to water level changes.

The Technology Behind the 2% Ball Float Valve

The term 2% ball float valve refers to the specific design and operational parameters of the valve. The 2% indicates that the valve operates effectively within a 2% margin of water level fluctuation. This precision allows for more stable control over the fluid levels in a system, which is crucial in processes requiring strict adherence to liquid levels.

The key components include a buoyant ball (the float), a valve body, an inlet, and an outlet. The float is typically made of materials such as plastic or stainless steel to enhance durability and prevent corrosion. The valve body houses the mechanism that responds to the float's movements.

Applications of the 2% Ball Float Valve

The versatility of the 2% ball float valve makes it suitable for various applications, including

1. Water Supply Systems In municipal or industrial water supply systems, maintaining the correct water levels is essential for ensuring adequate supply and pressure.

2. Aquaculture In fish farming, monitoring water levels is critical to the health of aquatic life. A 2% ball float valve can help maintain optimal water conditions.

3. Irrigation Agricultural irrigation systems benefit from this valve by preventing overflows or dry spells, thus optimizing water usage.

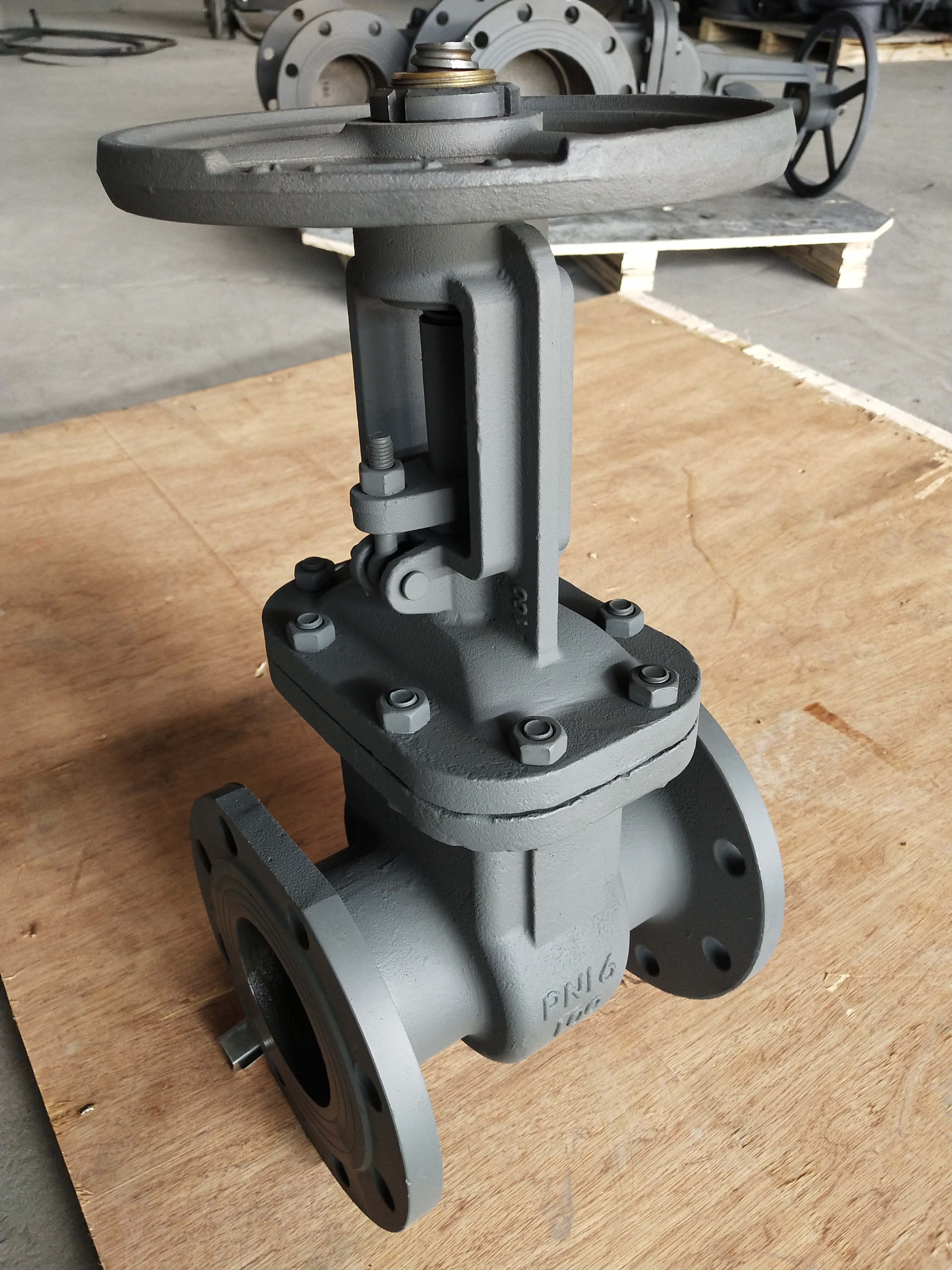

2 ball float valve

4. Wastewater Treatment Maintaining specific liquid levels in treatment facilities is necessary for effective processing and purification of wastewater.

5. Heating Systems In boilers and other heating systems, maintaining water levels is vital for safety and efficiency. The ball float valve helps to prevent overheating and system failure.

Advantages of the 2% Ball Float Valve

The 2% ball float valve boasts several advantages that make it a preferred choice in many applications

1. Precision Control The ability to function within a 2% range allows for more precise management of fluid levels, which can improve overall system efficiency.

2. Automated Operation The automatic operation of the ball float valve reduces the need for manual intervention, saving time and labor costs.

3. Reliability With fewer moving parts compared to other types of valves, the ball float valve is less prone to failure, leading to increased reliability and longer service life.

4. Reduced Maintenance The design and functionality of the 2% ball float valve often result in reduced maintenance needs over time, allowing for lower operational costs.

5. Versatility The valve can be employed in a wide range of applications, making it a staple in various industries.

Conclusion

The 2% ball float valve stands out as a crucial component for effective fluid management in numerous sectors. Its advanced design facilitates reliable and precise control over water levels, ensuring optimal performance while minimizing maintenance. As industries continue to seek efficiency and sustainability, understanding and utilizing such innovative solutions will remain indispensable. Whether in water supply systems, agriculture, or wastewater treatment, the 2% ball float valve plays a pivotal role in modern fluid management technologies.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025