Understanding the Functionality of a 2% Position 3-Way Solenoid Valve in Automation

Understanding the 2% Position 3-Way Solenoid Valve

A 2% position 3-way solenoid valve is an essential component in various pneumatic and hydraulic systems, widely used in industries such as automation, process control, and fluid management. This article aims to provide a comprehensive overview of what a 2% position 3-way solenoid valve is, its operating principles, applications, and advantages.

What is a 3-Way Solenoid Valve?

A 3-way solenoid valve is a type of valve that has three ports and can regulate the flow of fluids or gases within a system. Its main function is to either direct flow, stop flow, or divert fluid from one passage to another, allowing for versatile control over fluid dynamics. The three ports typically consist of an inlet, an outlet, and an external or secondary outlet.

In essence, a 3-way solenoid valve can operate in various modes depending on the specific design and configuration. When it is energized, the solenoid activates an internal mechanism that alters the connection between the ports. There are different types of 3-way solenoid valves, including the normally closed (NC), normally open (NO), and specific configurations designed to assist in various control schemes.

Understanding the 2% Positioning

The term 2% position refers to the precision of the valve's actuation in its stroke or movement. In the context of industrial automation and process control, precision in positioning is crucial for achieving desired outcomes while minimizing waste and optimizing performance. The 2% position indicates that the valve can be controlled to a degree of very high accuracy, which contributes to better flow regulation and increased efficiency in various applications.

Operating Principle

The 2% position 3-way solenoid valve operates through the use of electromagnetic force. Inside the valve, there is a coil that generates a magnetic field when electric current passes through it. This magnetic field pulls a plunger or armature, which then shifts the valve's position. The precision in the movement allows for controlled flow rates and quick responses to changes in system conditions.

Moreover, solenoid valves can be controlled using a relay or direct wiring to a programmable logic controller (PLC), ensuring that the system's operations are synchronized with other components, leading to integrated solutions in automation.

Applications

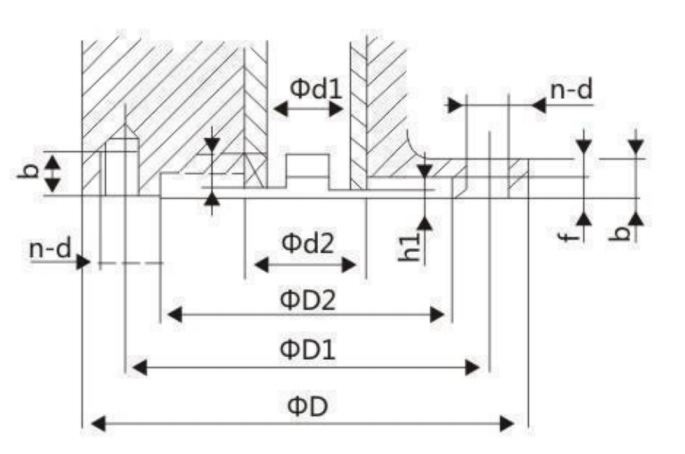

2 position 3 way solenoid valve

The versatility of the 2% position 3-way solenoid valve enables its use in various applications, including

1. Pneumatic Systems Used to control air flow in automation machinery and robots. 2. Hydraulic Systems Applies to applications where fluid control and pressure regulation are critical. 3. Process Control Common in industries such as food and beverage, pharmaceuticals, and chemical processing where the precise control of liquids is necessary. 4. HVAC Systems Used to manage the flow of refrigerants and enhance system efficiency. 5. Irrigation Systems Controls water distribution to optimize usage and conserve resources.

Advantages

1. Precision and Control The 2% position accuracy allows for meticulous control over flow rates, ensuring optimal operation in various processes.

2. Increased Efficiency By minimizing fluid wastage and ensuring timely operations, these valves contribute to overall system efficiency.

3. Reliability Solenoid valves are known for their durability and robustness, making them suitable for demanding environments.

4. Simple Integration They can easily be integrated into automated systems, thanks to standardized operating voltages and compatibility with control systems.

5. Quick Response Time The rapid actuation allows for faster changes in flow direction or status, crucial in dynamic environments.

Conclusion

The 2% position 3-way solenoid valve is a fundamental component in modern engineering applications, offering precision, reliability, and efficiency. By understanding its operation and potential applications, engineers and technicians can better integrate these valves into their systems, leading to improved performance and optimized processes. As industries continue to evolve towards automation and increased efficiency, the role of solenoid valves will undoubtedly remain significant.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025