Top Manufacturers of Two-Way Ball Valves for Industrial Applications

Understanding 2-Way Ball Valves A Comprehensive Guide to Manufacturers

2-way ball valves are essential components in various industrial processes, serving a fundamental role in managing the flow of liquids and gases. As a favored choice in the valve market, these devices offer simple yet effective mechanisms that enable or restrict flow based on their position. Understanding the manufacturers of 2-way ball valves can provide insights into their quality, reliability, and suitability for specific applications.

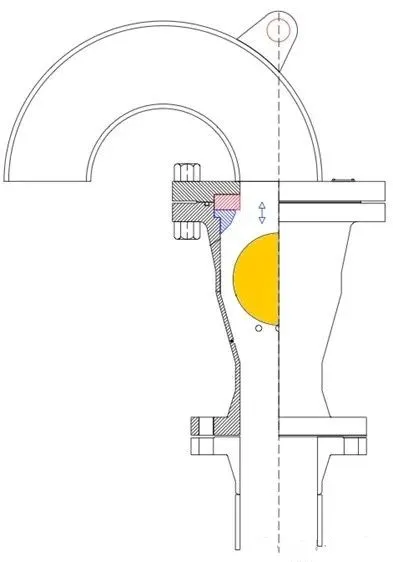

What is a 2-Way Ball Valve?

A 2-way ball valve consists of a spherical disc, known as the ball, that has a hole through its center. This ball is mounted in a way that it can rotate to allow or block flow. In its open position, the flow passes through the hole, while in the closed position, the ball turns, obstructing the flow path. This design makes 2-way ball valves highly efficient for on-off control in various systems.

Applications of 2-Way Ball Valves

2-way ball valves find applications across numerous industries, including plumbing, chemicals, food and beverage, pharmaceuticals, and oil and gas. Their robust design and reliable operation make them suitable for handling varying pressures and temperatures. They are particularly effective in applications where quick shut-off is necessary, providing a compact solution that saves space and increases efficiency.

The Importance of Selecting the Right Manufacturer

Choosing the right manufacturer of 2-way ball valves is critical for ensuring quality and performance. Manufacturers vary widely in terms of technology, materials, and production standards. A reputable manufacturer will offer products that comply with industry standards and certifications, ensuring safety and reliability. It's essential to consider the following factors when evaluating manufacturers

1. Material Quality The materials used in the construction of 2-way ball valves significantly affect their longevity and performance. Manufacturers should provide options for various materials, such as stainless steel, brass, and plastic, suitable for different environments and media types.

2. Design and Engineering Advanced design techniques can enhance the efficiency and performance of ball valves. Manufacturers that invest in R&D are more likely to produce innovative solutions that meet changing industry demands.

3. Production Processes Understanding a manufacturer’s production methods can provide insights into their quality control measures. Manufacturers that utilize automated machining processes often achieve higher precision and consistency in their products.

2 way ball valves manufacturers

4. Certifications and Standards Reliable manufacturers adhere to international standards such as ISO 9001, ANSI, and API. These certifications indicate a commitment to quality management and product reliability.

5. Customer Service and Support A responsive customer service team is vital for addressing inquiries, technical support, and after-sales service. Good communication can significantly enhance the overall customer experience.

Leading Manufacturers in the Market

Several prominent manufacturers specialize in producing 2-way ball valves, each offering distinct advantages. Some of the leading brands include

- Parker Hannifin Known for its extensive range of fluid control products, Parker offers durable and reliable 2-way ball valves suitable for various applications.

- Emerson With a strong focus on automation and controls, Emerson provides high-performance ball valves designed for complex industrial applications.

- Flowserve Recognized for their engineering excellence, Flowserve manufactures a wide selection of ball valves, including 2-way options, tailored to harsh environments.

- Crane Co. With a longstanding reputation in valve manufacturing, Crane produces robust 2-way ball valves backed by extensive industry experience.

- Valmet This manufacturer specializes in valves for the pulp and paper industry, offering custom solutions that enhance operational efficiency.

Conclusion

2-way ball valves are vital components in many industries, and selecting the right manufacturer can significantly impact performance and longevity. By understanding the key factors involved in the manufacturing process and being aware of leading manufacturers in the market, businesses can make informed choices that enhance their operational efficiency and reliability. Always ensure that the selected valves are appropriate for the specific application and conform to the necessary standards to guarantee optimal performance.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025