316 ss globe valve supplier

The Importance of Sourcing Quality 316 SS Globe Valve Suppliers

When it comes to industrial applications, the reliability and efficiency of valves play a crucial role in the overall performance of systems. One particular type of valve that has garnered attention in various industries is the globe valve, especially those made from 316 stainless steel (SS). The material properties of 316 SS make it an ideal choice for environments where corrosion resistance, durability, and temperature resilience are necessary. Consequently, understanding how to choose the right 316 SS globe valve supplier is vital for ensuring the operational success of your applications.

Why Choose 316 Stainless Steel?

316 stainless steel is an alloy that contains molybdenum, which enhances its corrosion resistance compared to other stainless steel grades like 304. This makes 316 SS particularly suitable for chemical processing, marine applications, and food processing, where exposure to harsh chemicals, saline environments, and high temperatures are common. The inherent mechanical properties of 316 SS also ensure that valves maintain their integrity under various operational stresses, making them a long-lasting choice.

The Role of Globe Valves in Industry

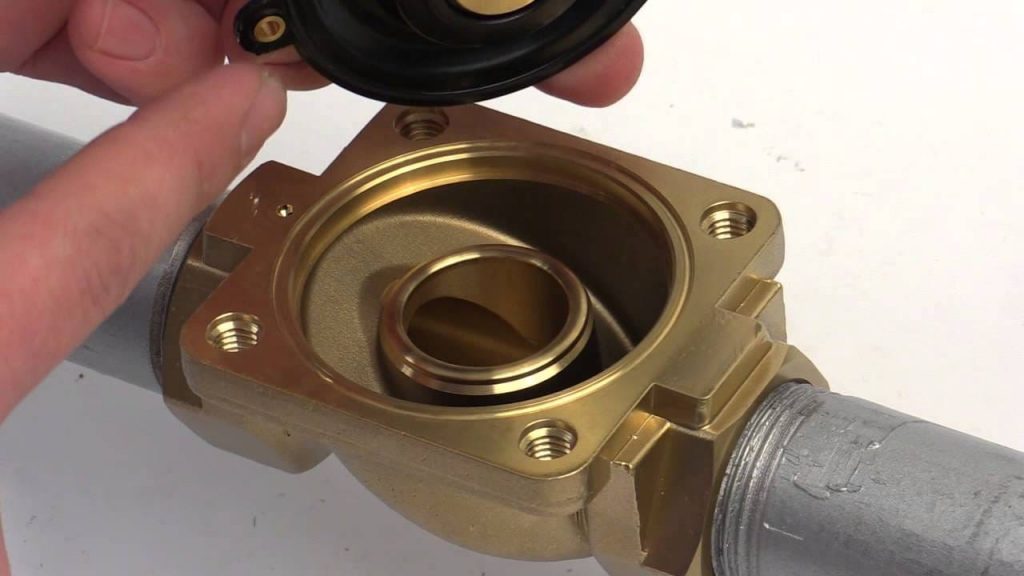

Globe valves are designed for regulating flow in pipelines, offering excellent throttling capabilities. Their spherical shape allows for greater control over fluid flow than other valve types. In many applications, such as water treatment facilities, oil and gas, and HVAC systems, globe valves facilitate precise adjustments to flow and pressure, ensuring optimal performance. As such, the selection of the right supplier for 316 SS globe valves is essential for maintaining operational integrity.

Key Factors to Consider When Choosing Suppliers

316 ss globe valve supplier

1. Quality Assurance Ensure that the supplier has stringent quality control measures in place. Look for certifications such as ISO 9001 which indicate that the supplier adheres to international quality standards. Quality assurance is crucial because inferior products can lead to valve failure, causing operational downtime and potentially hazardous situations.

2. Expertise and Experience Working with suppliers who have extensive industry experience can add significant value. Not only can they provide high-quality products, but they can also offer tailored solutions that meet the specific needs of your application. Supplier expertise often translates into better customer service and support during the purchasing process and afterward.

3. Product Range Opt for a supplier that offers a wide range of 316 SS globe valves with various sizes, pressure ratings, and design configurations. This variety allows you to choose the right valve for your specific application without having to compromise on quality or functionality.

4. Technical Support and Service The right supplier should provide ongoing technical support, including product installation guidance, maintenance tips, and troubleshooting assistance. Good customer service ensures that you can address any concerns or issues quickly, minimizing any potential disruptions to your operations.

5. Reputation and Reviews Researching the supplier's reputation in the market is vital. Look for customer testimonials and reviews to gauge other clients’ experiences. A supplier with a strong track record of delivering high-quality products and exceptional service is a valuable partner in your supply chain.

Conclusion

In conclusion, sourcing high-quality 316 stainless steel globe valves from a reputable supplier is crucial for industries relying on these essential components. The durability, corrosion resistance, and efficiency provided by 316 SS make it a preferred choice across various sectors. By prioritizing factors such as quality assurance, supplier expertise, product range, technical support, and market reputation, you can make informed decisions that will enhance your operational reliability and efficiency. Investing time in selecting the right supplier is not just a step in the purchasing process; it is an investment in the long-term success of your operations.

-

High-Security Lockable Gas Valve - Tamper-Proof ControlNewsAug.30,2025

-

Reliable Hydraulic Valves for Efficient Fluid ControlNewsAug.29,2025

-

Reliable Electric Actuators for Industrial Valve AutomationNewsAug.29,2025

-

Premium Line Blind Valves for Secure Pipeline IsolationNewsAug.29,2025

-

Premium Electric Valves for Smart Fluid Control SolutionsNewsAug.29,2025

-

Precision Balanced Valves for Optimal System PerformanceNewsAug.29,2025

-

Heavy-Duty Flanged Butterfly Valves for Water SystemsNewsAug.29,2025