3 inch gate valve supplier

Exploring the Importance and Supply of 3-Inch Gate Valves

Gate valves are critical components in various industrial applications, known for their ability to control fluid flow within pipelines. Among these, the 3-inch gate valve stands out due to its versatility and efficiency in numerous settings, from water supply systems to oil and gas industries. In this article, we will examine the significance of 3-inch gate valves, their applications, and the factors to consider when selecting a supplier.

Understanding 3-Inch Gate Valves

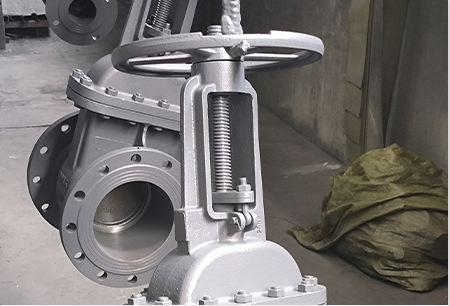

A gate valve is a type of linear valve that opens by lifting a gate out of the path of the fluid. This design allows for minimal resistance to flow, making them particularly advantageous for applications requiring a straight-line flow of fluid with very little pressure drop. The 3-inch gate valve, specifically, is designed to control larger volumes of fluid compared to smaller valves, making it suitable for various industrial needs.

The key features of a 3-inch gate valve include its durable construction, typically made from materials such as stainless steel, cast iron, or brass, allowing it to withstand high pressures and corrosive environments. Additionally, these valves can be operated manually with a wheel or an electric actuator, providing flexibility depending on the requirements of the operation.

Applications of 3-Inch Gate Valves

3-inch gate valves are used in a wide range of applications, including

1. Water Treatment Plants They regulate the flow of water and wastewater, ensuring efficient operations and meeting environmental standards. 2. Oil and Gas Industry The petroleum sector employs these valves to control the flow of crude oil, natural gas, and petrochemicals through pipelines.

4. Fire Protection Systems Gate valves play a vital role in fire hydrant systems, allowing firefighters to control water flow quickly during emergencies.

3 inch gate valve supplier

Choosing a Supplier for 3-Inch Gate Valves

When seeking suppliers for 3-inch gate valves, there are several crucial aspects to consider

1. Quality Assurance Ensure that the supplier adheres to industry standards and certifications, such as ISO 9001. Quality control measures should be in place, guaranteeing that the products meet the required specifications.

2. Material and Design Verify the materials used in the manufacturing process. Valves made from high-quality materials will have longer life spans and better performance under pressure.

3. Customization Options Depending on the specific requirements of your project, it might be necessary to discuss customization options. A good supplier should be able to provide various designs, seals, and actuator options to meet unique demands.

4. Technical Support and Service Post-purchase support is essential for installation and maintenance. Choose a supplier who offers comprehensive technical support, ensuring that any issues can be resolved swiftly.

5. Pricing and Delivery Timelines Compare prices from multiple suppliers, but keep in mind that the lowest price isn’t always the best choice. Consider the total cost of ownership, including installation and maintenance. Also, inquire about delivery timelines to ensure timely project completion.

6. Reputation and References Research the reputation of potential suppliers. Seek reviews and references from previous clients to gauge their reliability and service quality.

Conclusion

The significance of 3-inch gate valves in various industries cannot be overstated. Their role in fluid flow regulation, coupled with factors such as durability and efficiency, makes them indispensable in operations. By carefully selecting a reputable supplier, businesses can ensure that they invest in high-quality products that meet their operational requirements, ultimately leading to enhanced efficiency and safety in their applications. In a world where industrial processes continuously evolve, staying ahead with reliable components like the 3-inch gate valve is key to success.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025