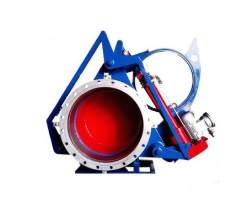

3 in gate valve manufacturers

Understanding the 3% in Gate Valve Manufacturers

Gate valves play a crucial role in various industrial applications, managing the flow of fluids in pipelines. As industries continue to evolve, the demand for high-quality, reliable valve manufacturers has surged, giving rise to various metrics for evaluating manufacturers' performance. One such metric is the 3% benchmark, which often indicates the expected performance standards, defect rates, or operational efficiencies among gate valve manufacturers.

The Significance of the 3% Benchmark

The 3% figure typically refers to the percentage of defective products that are acceptable within a manufacturing process. In the context of gate valve manufacturing, maintaining a defect rate below this threshold is crucial for ensuring product quality and reliability. This standard not only affects the manufacturers’ reputation but also has significant implications for end-users, particularly in industries such as oil and gas, water management, and chemical processing, where valve failure can lead to catastrophic results.

Gate valves are designed to provide a straight-line flow of fluid with minimal obstruction. When a gate valve is in the open position, the flow path is completely unobstructed, allowing for efficient flow. However, if the valves are not manufactured to the highest standards, the risk of defects such as improper sealing, corrosion, and mechanical failure increases, which can result in operational downtime and costly repairs.

Quality Control in Manufacturing

3 in gate valve manufacturers

To achieve the 3% benchmark, gate valve manufacturers implement stringent quality control measures throughout the production process. This includes rigorous testing and inspection of materials, manufacturing processes, and final products. Common quality control methods involve

1. Material Inspection Ensuring that the raw materials used are of high quality and compliant with relevant industry standards. This reduces the risk of material failure down the line. 2. Machining and Assembly Controls Monitoring the precision of machining processes and the quality of assembly to prevent issues that could lead to valve malfunctions. 3. Performance Testing Conducting extensive testing of the valves under operational conditions to ensure they can withstand the specified pressures and temperatures without failure.

4. Certification and Compliance Adhering to international standards such as ISO 9001 for quality management systems, which helps certify that the manufacturer consistently meets customer and regulatory requirements.

The Competitive Landscape

In the competitive landscape of gate valve manufacturing, companies that can reliably maintain a defect rate below 3% position themselves as leaders in the market. They gain customer trust, enhance their brand reputation, and ultimately drive sales growth. Furthermore, these manufacturers often invest in research and development to innovate and improve their product offerings, ensuring they meet the evolving needs of their customers.

In conclusion, the 3% benchmark is more than just a statistic for gate valve manufacturers; it embodies a commitment to quality and reliability. As industries continue to rely on gate valves for critical applications, manufacturers that prioritize quality control and operational excellence will continue to thrive and contribute to the safety and efficiency of fluid management systems worldwide.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025