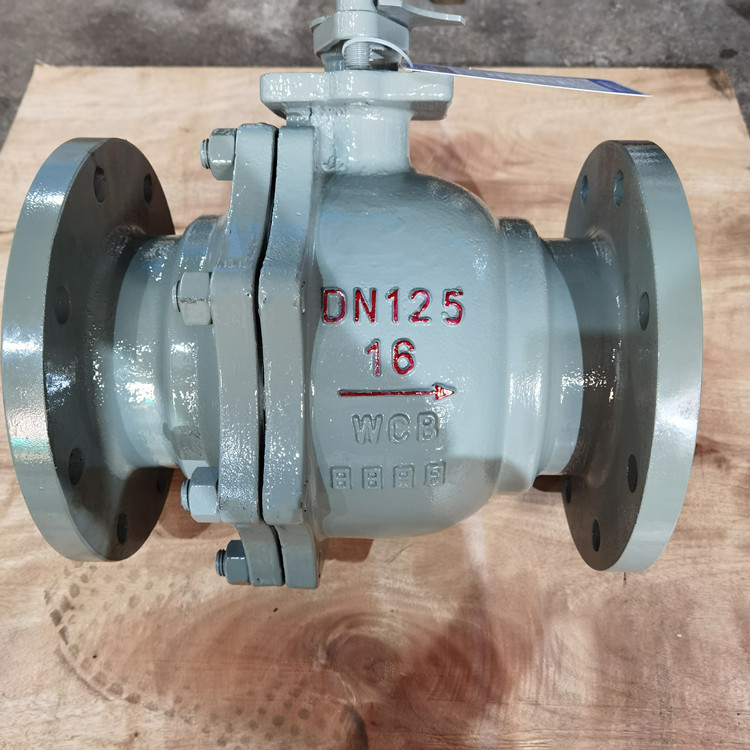

3 stainless steel butterfly valve

The Versatility of 3% Stainless Steel Butterfly Valves

Butterfly valves are essential components in various industrial applications, providing reliable flow control across numerous sectors, including water management, oil and gas, and chemical processing. Among the different materials used for these valves, 3% stainless steel stands out due to its unique combination of strength, corrosion resistance, and cost-effectiveness. This article explores the features, benefits, and applications of 3% stainless steel butterfly valves.

Features of 3% Stainless Steel Butterfly Valves

3% stainless steel, commonly known as austenitic stainless steel, contains a blend of chromium and nickel, providing excellent resistance to corrosion, particularly in harsh environments. This type of stainless steel is often referred to as 304 or 316 stainless steel, depending on the specific composition. The butterfly valve design features a disc that revolves around a central axis, allowing for rapid operation and efficient flow regulation.

These valves are characterized by their lightweight yet robust construction, making installation and maintenance straightforward. The smooth disc surface reduces turbulence, resulting in a minimal pressure drop across the valve, ensuring efficient flow control. Additionally, the design allows for quick opening and closing, making them ideal for applications requiring frequent operation.

Benefits of 3% Stainless Steel Butterfly Valves

3 stainless steel butterfly valve

One of the significant advantages of 3% stainless steel butterfly valves is their resistance to rust and corrosion

. This property makes them suitable for high-moisture environments and applications involving corrosive substances. Moreover, their durability extends the lifespan of the valve, reducing the frequency and cost of replacements.Another benefit lies in their ease of maintenance. Since butterfly valves have a simple design with fewer moving parts compared to other valve types, maintenance tasks can often be performed quickly, minimizing downtime in industrial processes. Additionally, the lightweight nature of these valves reduces the structural requirements of piping systems, often leading to lower installation costs.

Applications of 3% Stainless Steel Butterfly Valves

3% stainless steel butterfly valves are widely used in many industries. In the chemical processing sector, they provide vital isolation and flow control for various chemicals, preventing leaks and maintaining safety standards. In water treatment facilities, these valves manage the flow of water and sludge, playing a crucial role in the purification process.

In the food and beverage industry, the non-reactive surface of stainless steel ensures that no contaminants leach into the products. They are also increasingly utilized in HVAC systems for regulating airflow efficiently.

In conclusion, 3% stainless steel butterfly valves are an excellent choice for various applications due to their combination of durability, corrosion resistance, and ease of maintenance. As industries continue to evolve, the demand for reliable and efficient flow control solutions will only increase, reaffirming the significance of these valves in modern engineering. Whether in demanding environments or everyday applications, 3% stainless steel butterfly valves offer the reliability and performance needed to meet the challenges of contemporary industrial processes.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025