Innovative Design Features of 4% 150 Flange for Enhanced Performance and Durability

Understanding 4% 150% Flange A Comprehensive Overview

Flanges are critical components in various engineering applications, especially in piping systems, where they facilitate the connections between pipes, valves, pumps, and other equipment. Among the wide array of flange types and specifications, the term 4% 150% flange merits discussion due to its unique design and functionality.

What is a Flange?

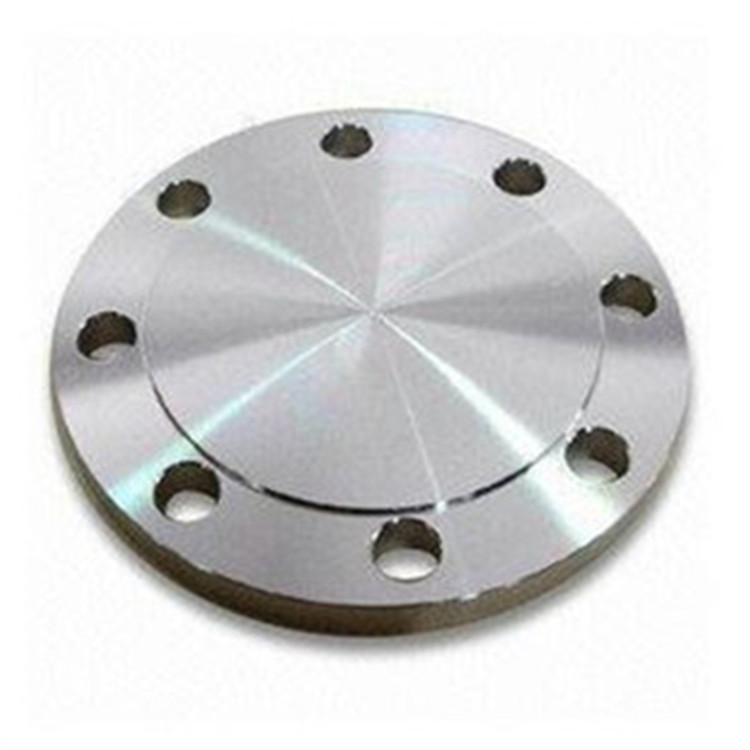

A flange is a flat piece of metal, often in the shape of a disc, that is welded or bolted to the end of pipes or other components. Flanges serve multiple purposes they provide a tight seal, enable disassembly for maintenance or inspection, and allow for the alignment of multiple components. They come in various sizes, pressure ratings, and materials, making them versatile for multiple applications in industries such as oil and gas, chemical processing, water treatment, and construction.

The Significance of 4% 150% Flanges

The designation 4% 150% typically refers to the specific dimensions and pressure ratings of the flange. In pressure contexts, the number following the % denotes the pressure class. The 150 indicates that this flange type can handle up to 150 pounds per square inch (psi) of pressure. Meanwhile, the 4% can be interpreted as a reference to a tolerance or design parameter that indicates a deviation percentage.

Key Features

1. Design and Material 4% 150% flanges are often constructed from robust materials such as carbon steel, stainless steel, or other alloys. The choice of material depends on the working environment. For instance, stainless steel flanges are commonly used in corrosive conditions due to their high resistance to rust and corrosion.

2. Versatility These flanges can be used in a wide range of applications. Whether connecting two pipes in a water treatment facility or linking a pump to a valve in a chemical processing plant, the 4% 150% flange is designed to provide safety and reliability.

3. Ease of Installation Flanges designed for 150 psi applications typically feature standardized bolt holes, making them easy to install and remove. Proper installation is vital to ensure that flanges maintain their seal under pressure, preventing leaks and system failures.

4 150 flange

4. Compliance with Standards Flanges often adhere to industry standards such as ASME (American Society of Mechanical Engineers) and ANSI (American National Standards Institute). This compliance ensures that the flanges can withstand the necessary pressures and temperatures while ensuring a uniform quality across manufacturers.

Applications

The applications of the 4% 150% flange are vast and varied

- Oil and Gas Industry Due to their durability and pressure rating, these flanges are frequently used to connect pipes in critical systems transporting oil, gas, and other resources. - Water Treatment In water treatment facilities, these flanges help maintain the integrity of the system as they connect various treatment equipment.

- Chemical Processing Chemical plants often require reliable connections between different equipment to ensure safety and efficiency. The 4% 150% flange provides the necessary strength.

Maintenance and Inspection

Regular maintenance and inspection of flanges is important to ensure their reliability. Signs of wear, such as corrosion or cracks, can indicate the need for a replacement. Proper torque specifications during installation and regular checking can prevent failures.

Conclusion

The 4% 150% flange represents an essential element in many industrial applications, combining strength, versatility, and reliability. Understanding its characteristics and proper maintenance can help enhance the safety and efficiency of various systems, ultimately contributing to smoother operations in engineering environments. Whether in oil and gas, chemical processing, or water treatment, the importance of these flanges cannot be understated.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025