42-inch Butterfly Valve Overview and Applications for Industrial Use

Understanding the 42% Butterfly Valve An Essential Component in Fluid Control

In the realm of industrial automation and fluid control, the choice of valves plays a pivotal role in ensuring efficient operations. Among various types, the butterfly valve is particularly notable for its compact design and effective flow regulation capabilities. This article will delve into the specifics of a 42% butterfly valve, discussing its construction, applications, advantages, and important considerations for selection.

What is a Butterfly Valve?

A butterfly valve is a type of quarter-turn rotational valve that uses a circular disc (the butterfly) to regulate flow. The disc is mounted on a spindle and spins in the center of the pipe. When the valve is fully open, the disc is parallel to the flow, offering minimal resistance. Conversely, when closed, it rotates 90 degrees to block the flow. The 42% designation refers to the valve's diameter relative to the pipe size it is designed to fit, which in this case is a 42-inch diameter.

Construction and Operation

A typical 42-inch butterfly valve consists of several key components

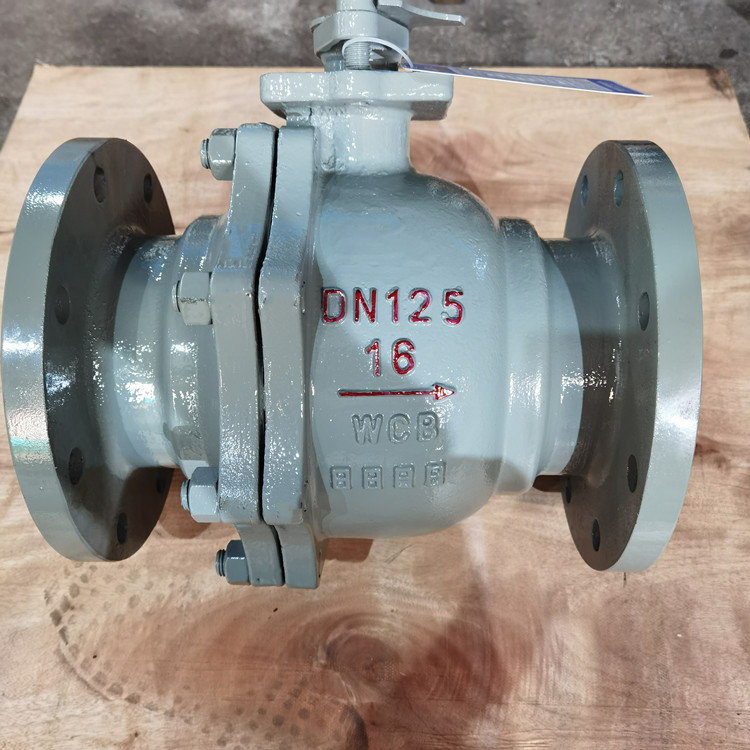

1. Body Made from durable materials such as cast iron, stainless steel, or plastic, the body houses the internal components and withstands high pressure and temperature conditions.

2. Disc The disc is the critical element that opens and closes to control flow. Its material is chosen based on the application’s specific needs, such as resistance to corrosion.

3. Stem The stem connects the disc to the actuator, allowing for movement. Stems can be manual or automated, depending on the application.

4. Actuator An actuator can be manual (handwheel) or automated (electric, pneumatic, or hydraulic), providing the necessary force to rotate the disc.

5. Seals Seals create a tight barrier to prevent leaks, critical for maintaining the system’s integrity.

Applications of 42% Butterfly Valves

42% butterfly valves are versatile components used across various industries, including

- Water and Wastewater Treatment Used to regulate flow in treatment plants and ensure proper distribution of treated water.

- Chemical Processing Handles aggressive fluids and ensures safe operational controls in chemical plants.

- Power Generation Controls steam and cooling water flow in power plants, contributing to energy efficiency.

42 inch butterfly valve

- HVAC Systems Regulates airflow in heating, ventilation, and air conditioning systems to ensure comfort and efficiency.

Advantages of Butterfly Valves

2. Cost-Effective Generally, butterfly valves are less expensive than other valve types, which is advantageous for large-scale installations.

3. Quick Operation The quarter-turn operation allows for fast opening and closing, which is crucial in emergency situations.

4. Low Pressure Drop When fully open, butterfly valves present minimal resistance to flow, making them energy-efficient.

5. Versatility Suitable for various media, including liquids, gases, and slurries, butterfly valves are adaptable for numerous applications.

Key Considerations for Selection

When selecting a 42% butterfly valve, several factors must be considered

- Material Compatibility Choose materials based on the fluid properties, including temperature, pressure, and corrosiveness.

- Size and Flow Requirements Ensure the valve size matches the piping system and meets flow requirements for the application.

- Actuation Method Determine whether manual or automated actuation is necessary based on the operational needs.

- Pressure and Temperature Ratings Ensure the valve can withstand the operational conditions to prevent failures.

Conclusion

The 42% butterfly valve stands as a crucial component in fluid control systems, offering a blend of efficiency, cost-effectiveness, and reliability. Understanding its construction, applications, and advantages can facilitate better selection and maintenance, enabling industries to operate smoothly while managing essential fluids. As technology continues to advance, the designs and functionalities of butterfly valves will likely evolve, further enhancing their role in industrial applications.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025