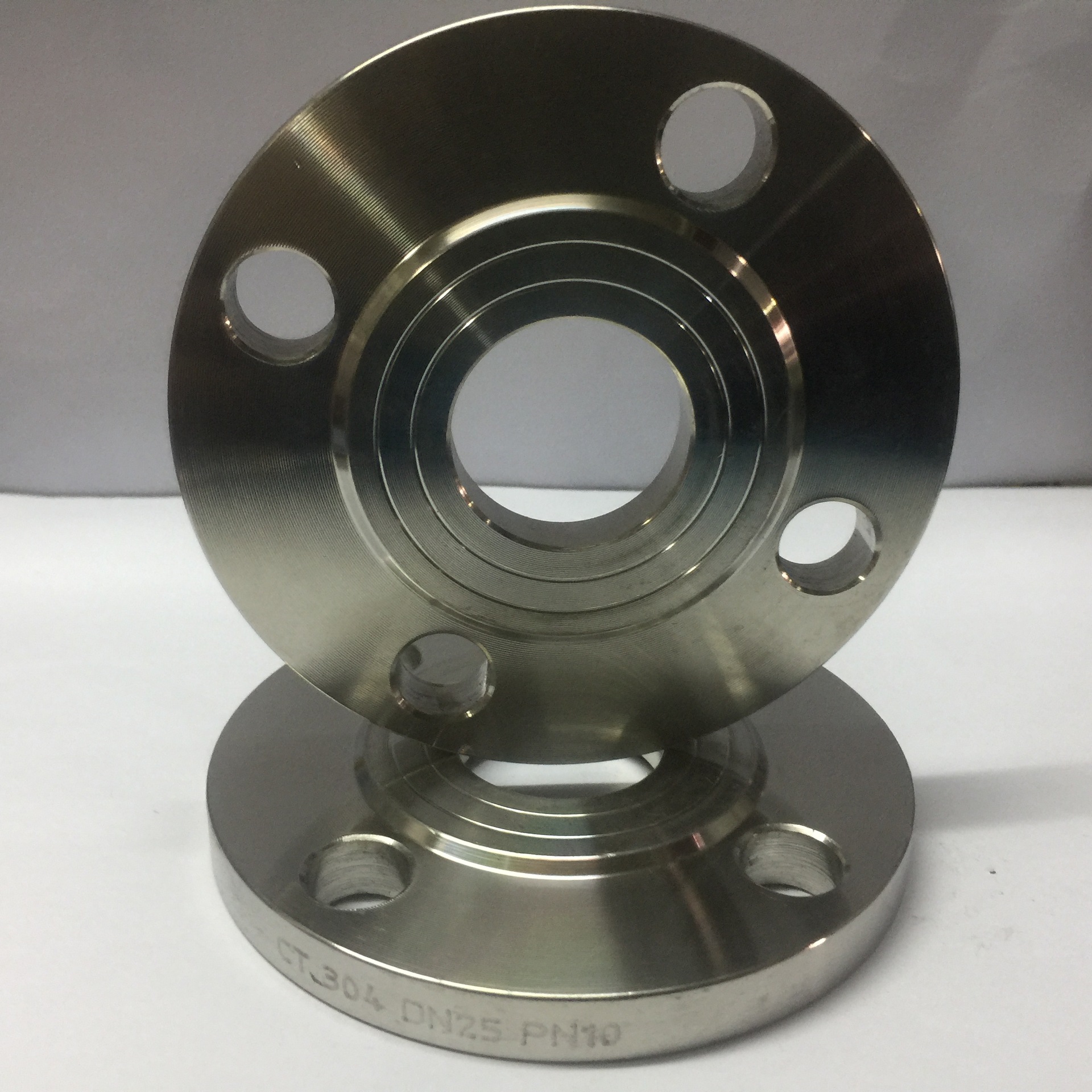

5 blind flange

Understanding the 5% Blind Flange Applications and Benefits

In various fields of industrial engineering, strength, safety, and efficiency are paramount. Among the critical components used in piping systems, blind flanges play a significant role, and specifically, the 5% blind flange is causing a stir due to its specialized applications and advantages. This article delves into what a 5% blind flange is, its features, engineering benefits, and applications in different industries.

What is a Blind Flange?

A blind flange is a solid disk that covers the ends of piping systems. It is a crucial component that allows systems to be sealed off for maintenance, testing, or in situations where the piping configuration changes. Unlike standard flanges, which are used to join two sections of pipe, blind flanges do not have a central hole and thus prevent any fluid from passing through.

What Does 5% Mean?

The term 5% in the context of blind flanges typically refers to the pressure rating and design parameters that are engineered to withstand specific operational conditions. In other words, a 5% blind flange indicates that it can handle pressure ratings up to 5% greater than the maximum working limit defined by industry standards while maintaining integrity. This feature is particularly important in high-pressure applications where even small fluctuations can lead to catastrophic failures.

Key Features of 5% Blind Flanges

1. Material Composition The 5% blind flanges are typically fabricated from robust materials such as stainless steel, carbon steel, or alloys that resist corrosion and wear. This enhances their longevity and reliability.

2. Design Standards These flanges comply with stringent engineering standards such as ASME or ANSI, ensuring that they can handle the intended loads and stress over time.

3. Customization Engineers can often customize blind flanges to meet specific industry requirements. This includes variations in thickness, diameter, and pressure class to accommodate diverse applications.

4. Ease of Installation Blind flanges are designed for straightforward installation processes, which are crucial in industrial settings where downtime can result in significant losses.

Applications of 5% Blind Flanges

The versatility of 5% blind flanges allows them to be used in an array of industries

5 blind flange

1. Oil and Gas Sector They are widely utilized in pipelines, helping to securely seal pipe ends during maintenance or system modifications. This is critical for maintaining system integrity under high-pressure conditions.

2. Chemical Processing In the chemical industry, where corrosive substances are often handled, 5% blind flanges are essential to ensure that systems can be shut off completely during maintenance or emergency situations.

3. Water Treatment Facilities These flanges help prevent leaks and manage hydraulic pressures effectively within water supply systems.

4. Power Plants In nuclear or fossil fuel power plants, blind flanges are important components of safety systems, helping to isolate sections of piping to conduct repairs or inspections.

5. Construction and Building In HVAC systems, plumbing, and fire protection systems, 5% blind flanges are utilized for isolating sections of the piping, enhancing the safety and operational reliability of the overall system.

Benefits of Using 5% Blind Flanges

The use of 5% blind flanges brings numerous benefits

- Improved Safety By providing an effective seal under pressure, these flanges help prevent leaks that could have catastrophic consequences.

- Cost-Effective Solutions Their durability and reliability decrease the likelihood of repairs, further translating to lower maintenance costs.

- Flexibility in Design Customizable options allow for tailored solutions that meet specific engineering needs.

- Enhanced Performance The ability to withstand higher pressures ensures that processes run smoothly without interruptions.

Conclusion

As systems continue to evolve, the role of components such as the 5% blind flange becomes increasingly critical. Understanding their importance not only enhances the efficiency of industrial operations but also contributes to overall safety and sustainability within various sectors. With continued innovations in materials and design standards, the future of blind flanges looks promising, poised to meet the demands of modern engineering challenges.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025