6 plug valve

Understanding 6% Plug Valves An Overview

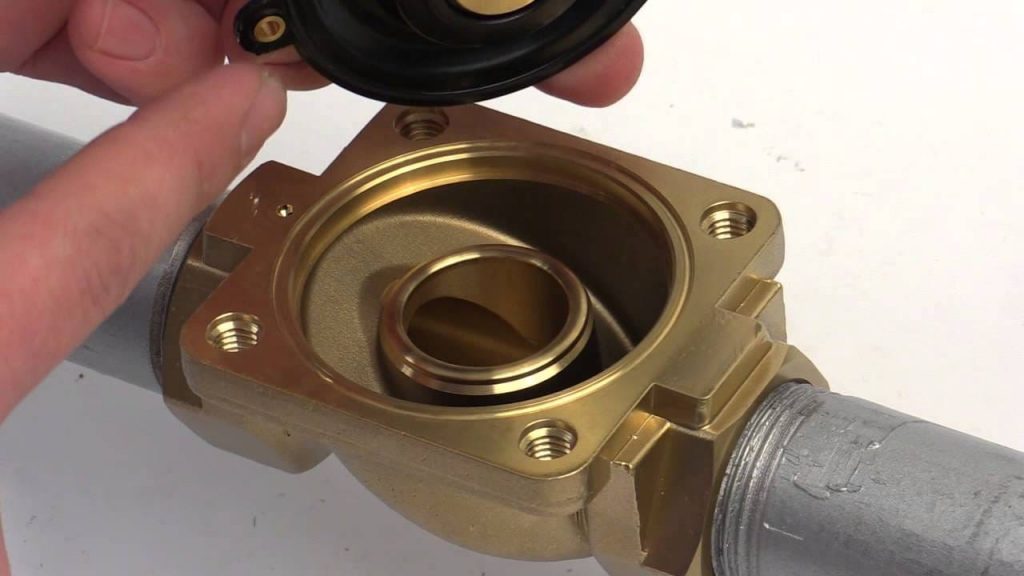

Plug valves are essential components in various industrial applications, serving as reliable devices for controlling fluid flow. Among these, the 6% plug valve stands out due to its unique design and operational efficiency.

Understanding 6% Plug Valves An Overview

One of the key advantages of 6% plug valves is their ability to provide a tight seal. The design minimizes leakage, which is crucial in applications involving hazardous or expensive fluids. Moreover, the simplicity of their operation allows for quick and easy adjustments, making them preferable in situations where rapid modulation is necessary.

6 plug valve

In terms of materials, 6% plug valves are often constructed from robust substances such as stainless steel, bronze, or PVC, enabling them to withstand high temperatures and pressures. This versatility makes them suitable for various industries, including oil and gas, water treatment, chemical manufacturing, and pharmaceuticals.

Another important consideration is the valve’s maintenance. Plug valves are generally straightforward to maintain, with fewer moving parts than other valve types. This simplicity means that they can often be serviced without the need for specialized tools, reducing downtime and operational costs.

Furthermore, 6% plug valves can be equipped with different actuators, allowing for manual or automated operation. This flexibility caters to a wide spectrum of needs in industrial applications, from powering machinery to controlling fluid processes in large-scale production lines.

In conclusion, the 6% plug valve serves as a crucial element in fluid control systems across various industries. Its design emphasizes reliability, efficiency, and ease of maintenance, making it a favored choice among engineers and operators alike. Whether dealing with corrosive substances, high-pressure environments, or the need for precise flow control, the 6% plug valve demonstrates its stature as both a practical and efficient solution. Future advancements in materials and design will likely enhance its functionality even further, ensuring that it remains a staple in the toolbox of fluid management solutions.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025