Design and Specifications of 6% 150% Blind Flange for Industrial Applications

Understanding 6% 150% Blind Flanges Applications and Benefits

In the world of piping systems, flanges play a crucial role in connecting various components effectively. Among the various types of flanges available, the blind flange stands out for its unique functionality and wide-ranging applications. This article delves into the specifics of 6% 150% blind flanges, their applications, benefits, and considerations when using them in various industries.

What is a Blind Flange?

A blind flange is a type of flange that is used to seal the end of a piping system. Unlike regular flanges that connect two pieces of pipe or equipment, blind flanges do not have a hole in the center. This feature allows them to effectively close off a section of piping, serving as an end cap. They are often used in places where future extensions might be required, or where a temporary closure is needed in a piping system.

The Significance of 6% 150% Designation

The designation 6% 150% in relation to blind flanges typically refers to the pressure class and the specification of the flange. In this context, 6% usually implies a specific weight or material thickness that adheres to certain industry standards, while 150% denotes the pressure rating of the flange, which is based on the American National Standards Institute (ANSI).

A 150-pound pressure rating is common for flanges used in various industrial applications, indicating that the flange is designed to withstand pressures up to 150 psi. The “6%” aspect may also relate to the material composition, detailing how the flange's weight meets the required structural integrity for safe operational performance.

Common Applications of 6% 150% Blind Flanges

Blind flanges are utilized in numerous industries, including oil and gas, chemical processing, water treatment, and HVAC systems. Their specific applications include

1. Pipeline Closure They are often used to close off the ends of pipelines, preventing leakage and maintaining system integrity during maintenance or inspection periods. 2. Equipment Maintenance When a section of a piping system requires maintenance, blind flanges can serve as temporary closure points, allowing other sections to remain operational.

3. Future Expansion Engineers often incorporate blind flanges into designs for future expansions, ensuring that additional piping can be easily added without extensive modifications.

6 150 blind flange

4. Fluid Containment In systems where fluids are transported, blind flanges help to ensure that there are no leaks at the ends of pipes, thus safeguarding both the environment and manufacturing processes.

Benefits of Using 6% 150% Blind Flanges

1. Cost-Effective Blind flanges are generally less expensive than other types of flanges because they don’t require as much material for production and are often simpler to manufacture.

2. Versatility They come in various sizes and materials, including stainless steel, carbon steel, and PVC, allowing them to be suitable for a range of applications and environments.

3. Ease of Maintenance The simplicity of using blind flanges facilitates quick maintenance and repairs within a piping system, reducing downtime and enhancing productivity.

4. Safety By efficiently sealing off sections of pipe, blind flanges enhance the safety of systems by preventing accidental leaks and the potential for explosive environments, especially in high-pressure scenarios.

Considerations When Using Blind Flanges

While blind flanges offer numerous benefits, there are also considerations to keep in mind. Proper installation is crucial; flanges must be aligned correctly and torqued to the manufacturer's specifications to prevent leakage or failure. Additionally, selecting the right material for the specific application is important, especially when dealing with corrosive substances or high-pressure environments.

Conclusion

6% 150% blind flanges are an essential component in various piping systems across many industries. Their ability to provide reliable sealing solutions makes them invaluable for temporary closures, maintenance tasks, and future expansion. By understanding their applications and benefits, engineers and technicians can better utilize blind flanges to enhance the safety and efficiency of their systems. As industries continue to evolve, the demand for reliable and cost-effective solutions like blind flanges will only increase, solidifying their place in the realm of industrial piping solutions.

-

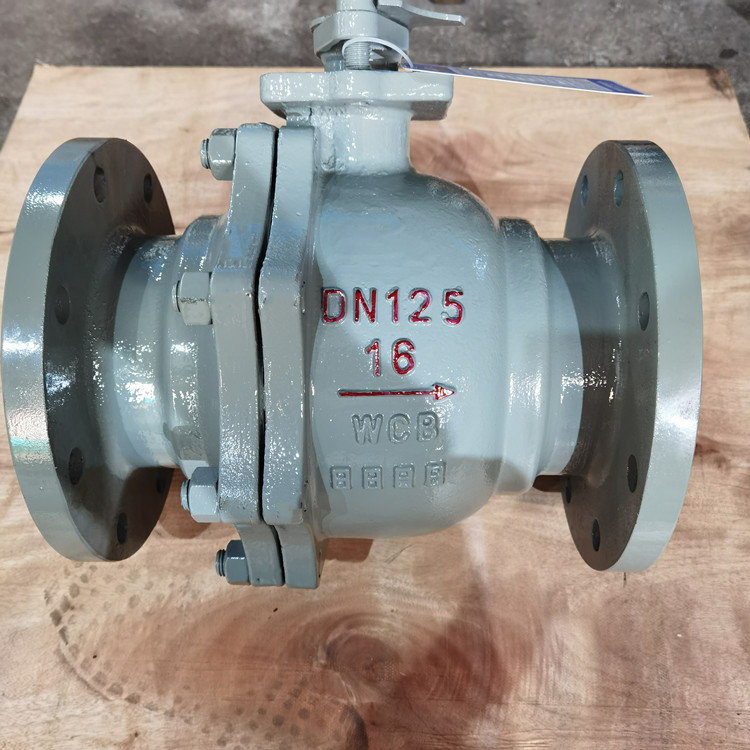

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025