A Comprehensive Guide to A105 Blind Flanges and Their Applications

Understanding A105 Blind Flanges A Comprehensive Overview

Flanges play a crucial role in piping systems, providing strong connections between different parts of piping infrastructure. Among the various types of flanges available in the market, the A105 blind flange holds a significant position due to its durability and versatility. This article aims to delve into the intricacies of the A105 blind flange, including its specifications, applications, advantages, and factors to consider when choosing one.

What is an A105 Blind Flange?

An A105 blind flange is a type of flange used to close off the ends of piping or valves. Classified under ASTM A105, it is made from carbon steel, making it suitable for high-temperature and high-pressure applications. The blind designation indicates that it does not have a bore, meaning it acts as a closure rather than a connection point for other pipes or fittings.

Specifications of A105 Blind Flanges

A105 blind flanges come with specific dimensions and properties that make them ideal for various industries. Typical specifications include

- Material Carbon steel, often with the use of standard grades like ASTM A105. - Pressure Ratings Available in various pressure ratings, including ANSI Class 150, 300, and 600. The pressure class determines the flange's ability to handle internal pressure. - Size Variability Ranges from 1/2 inch to 60 inches in diameter, accommodating different piping needs. - Temperature Ratings This flange design can withstand a range of temperatures, typically up to 350 degrees Fahrenheit (approximately 177 degrees Celsius).

The mechanical properties of ASTM A105 include high tensile strength and robustness, making these flanges ideal for heavy-duty applications.

Applications of A105 Blind Flanges

A105 blind flanges are commonly used in a variety of industries, including

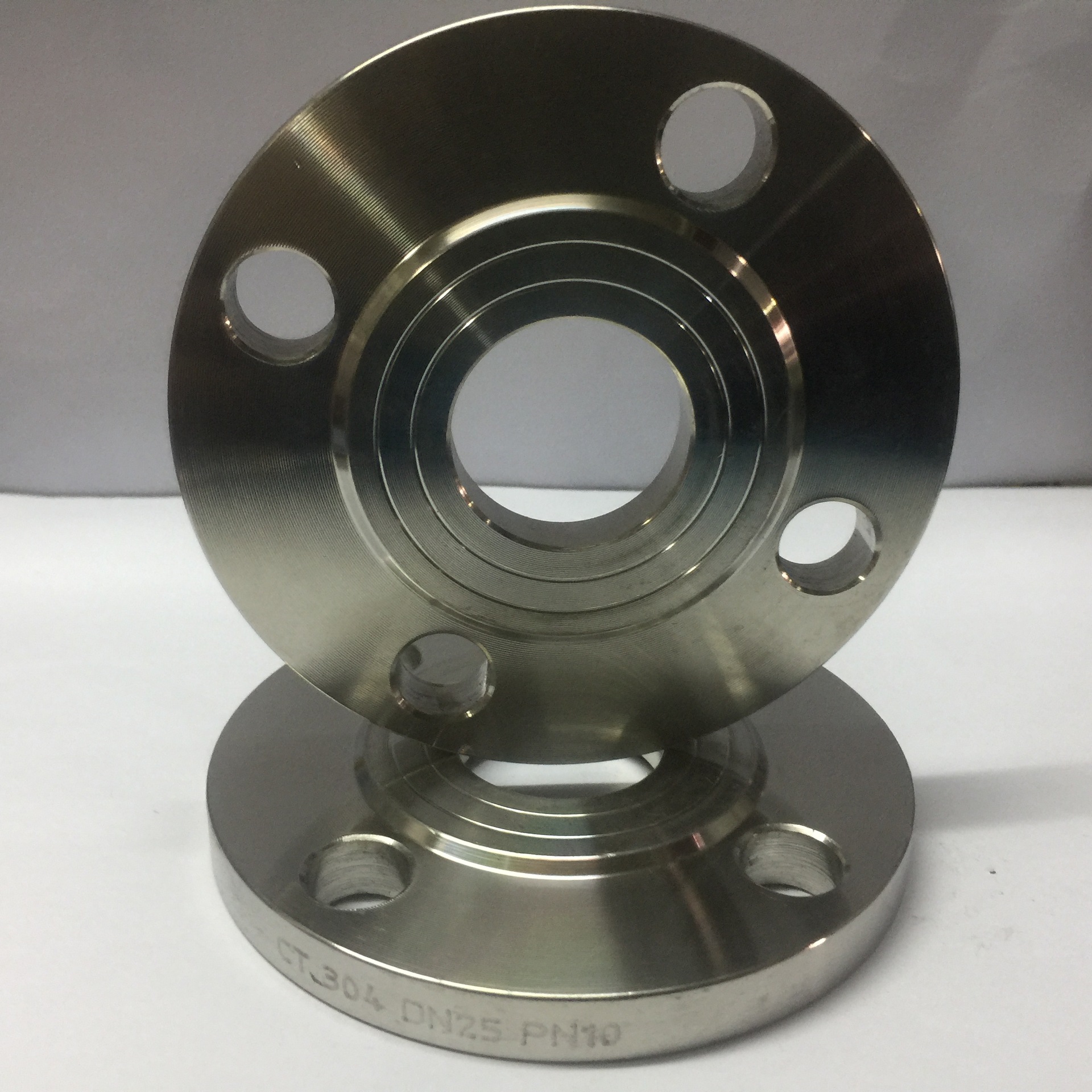

a105 blind flange

1. Oil and Gas Used in pipelines and refineries where piping systems need to be securely closed off for maintenance or safety reasons. 2. Chemical Processing These flanges can handle the aggressive nature of many chemicals and are crucial in preventing leaks in hazardous environments. 3. Waterworks Employed in systems that require strong, leak-proof connections. 4. Power Generation Utilized in plants where high pressure and temperature resistance are essential for keeping systems operational.

Advantages of A105 Blind Flanges

Using A105 blind flanges comes with several advantages

1. Cost-Effectiveness Compared to other materials, carbon steel is often more affordable, making A105 blind flanges an economical choice for many projects. 2. Ease of Installation Blind flanges are relatively easy to install, which helps save time and labor costs on construction jobs. 3. Compatibility A105 flanges are compatible with various piping materials and sizes, allowing for flexible use across an array of applications. 4. Robustness Their ability to withstand high pressure and temperatures makes them reliable for use in demanding environments.

Considerations When Choosing A105 Blind Flanges

When selecting A105 blind flanges for a project, it's essential to consider various factors

1. Pressure and Temperature Ratings Ensure the chosen flange can meet or exceed the pressure and temperature conditions of your application. 2. Sourcing Quality Materials It's crucial to purchase from reputable suppliers who provide flanges that meet ASTM standards. 3. Surface Finish The finish of the flange can affect its performance. Adequate surface treatment helps enhance corrosion resistance. 4. Gasket Compatibility Choosing the right gasket material to pair with the flange is vital to ensure a complete seal and prevent leaks.

Conclusion

A105 blind flanges are vital components in various piping systems across multiple industries. Their adaptability, cost-effectiveness, and ability to handle demanding conditions make them an indispensable choice for engineers and manufacturing professionals alike. Understanding their specifications, applications, and advantages aids in making informed decisions during the design and implementation of piping systems. As industries continue to evolve, the demand for reliable and efficient piping components like A105 blind flanges will undoubtedly remain strong.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025