Customizable Hydraulic Pressure Control Valve for Enhanced System Performance and Efficiency

Adjustable Hydraulic Pressure Control Valve A Comprehensive Overview

Hydraulic systems are pivotal in various industrial applications, ranging from manufacturing machines to automotive systems. Among the critical components that ensure the efficiency and safety of these systems are adjustable hydraulic pressure control valves. These devices play a crucial role in regulating pressure levels, thus safeguarding machinery from potential damage while maximizing operational efficiency.

What Is an Adjustable Hydraulic Pressure Control Valve?

An adjustable hydraulic pressure control valve is designed to modulate the pressure within a hydraulic system. Unlike fixed pressure valves, which maintain a set pressure, adjustable valves allow for customization according to specific operational requirements. This adjustability makes them suitable for a wide range of applications, including construction equipment, agricultural machinery, and industrial automation systems.

How Does It Work?

The core functionality of an adjustable hydraulic pressure control valve hinges on its ability to regulate the flow of hydraulic fluid. When the pressure in the hydraulic system exceeds a predetermined setpoint, the valve reacts by redirecting the flow, thereby preventing pressure build-up.

Typically, these valves are equipped with an adjustment mechanism, such as a screw or dial, that allows operators to set the desired pressure level. The valve's internal components, including springs and pistons, then work together to maintain this pressure, ensuring that the hydraulic system operates within a safe and effective range.

Key Benefits

1. Enhanced Safety The foremost advantage of using an adjustable hydraulic pressure control valve is the increased safety it offers. By preventing excessive pressure from accumulating in the system, the valve minimizes the risk of equipment failure and accidents.

adjustable hydraulic pressure control valve

2. Improved Efficiency Adjustable valves contribute to the overall efficiency of hydraulic systems. By allowing operators to set specific pressure levels tailored to their tasks, these valves help optimize performance, reduce energy consumption, and extend the lifespan of machinery.

3. Versatility The adjustable nature of these valves makes them suitable for various applications. Whether in a dynamic manufacturing environment or a more stable agricultural setting, they can be fine-tuned to meet diverse operational needs.

4. Cost-Effectiveness While the initial investment in adjustable pressure control valves may be higher than that of fixed valves, the long-term savings they provide are substantial. By preventing damage to equipment and improving energy efficiency, these valves can significantly lower maintenance costs and increase productivity.

Applications

Adjustable hydraulic pressure control valves find use in numerous sectors. In construction, they help manage the pressure in hydraulic cranes and excavators, enabling operators to perform tasks safely and effectively. In automotive systems, these valves regulate braking pressure and steering functions, ensuring both responsiveness and safety.

In manufacturing, adjustable valves are often employed in hydraulic presses and assembly lines, where consistent pressure is vital for quality control. Agricultural machinery also benefits from these valves, as they help manage the hydraulic systems in tractors and harvesters, ensuring optimal performance during operation.

Conclusion

Adjustable hydraulic pressure control valves are essential components of modern hydraulic systems. Their ability to maintain safe pressure levels while enhancing efficiency makes them invaluable across various industries. As technology continues to advance, the design and functionality of these valves are likely to evolve, offering even greater precision and control in hydraulic applications.

Investing in high-quality adjustable hydraulic pressure control valves is a prudent decision for any organization that relies on hydraulic systems. By ensuring that these systems operate safely and efficiently, businesses can protect their investments, improve operational performance, and ultimately drive success in their respective fields.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

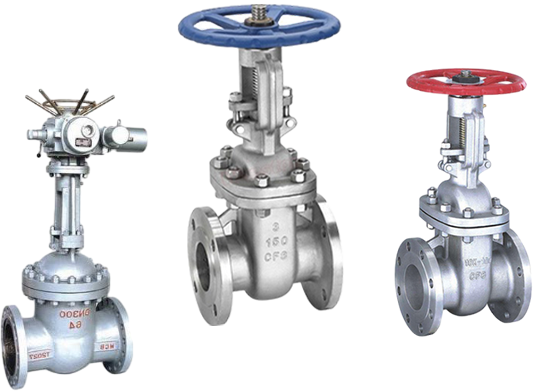

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025