Top Manufacturers of Air Control Valves for Industrial Applications

The Future of Air Control Valve Manufacturers

Air control valves play a vital role in a myriad of industries, including HVAC, automotive, and manufacturing. These components regulate airflow, ensuring systems operate efficiently and effectively. As technology advances, air control valve manufacturers are adapting to meet the evolving demands of the market while focusing on sustainability, efficiency, and innovation.

Understanding Air Control Valves

At its core, an air control valve is designed to manage the flow of air in a system. This is critical for maintaining optimal performance in various applications, from controlling air in a building's ventilation system to managing pressure in a vehicle's engine. The valve's primary function is to open or close in response to specific signals, allowing for precise control over airflow.

Manufacturers of these valves specialize in creating products that can withstand various environmental conditions, ensuring reliability and longevity. Common materials used in construction include metals, plastics, and ceramics, each selected based on the intended application and required durability.

The Current Landscape of Air Control Valve Manufacturing

The air control valve manufacturing industry is currently experiencing significant changes due to advancements in technology. Automation and smart technologies are becoming increasingly prevalent, allowing for real-time monitoring and control of airflow systems. This trend is driven by the growing demand for energy-efficient and intelligent solutions that reduce waste and improve performance.

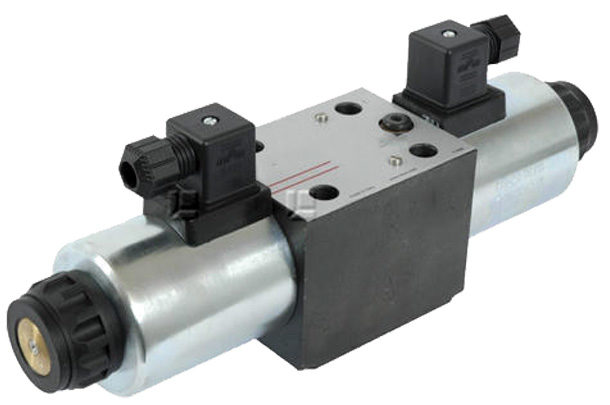

air control valve manufacturers

Moreover, the integration of IoT (Internet of Things) in air control valves is reshaping how manufacturers design their products. With sensors and connectivity, these valves can communicate with other system components, facilitating automated adjustments and enhancing overall system efficiency. For instance, smart air control valves can adapt their operation based on indoor air quality measurements, ensuring healthier living environments.

Sustainability and Environmental Awareness

Another critical focus for air control valve manufacturers is sustainability. In recent years, there has been a significant push towards greener manufacturing practices and products. Companies are investing in research and development to create valves that not only meet performance standards but also minimize environmental impact.

This commitment to sustainability often involves using recyclable materials, reducing energy consumption in production processes, and designing products that contribute to energy savings in their application. As industries worldwide aim for lower carbon footprints, air control valve manufacturers need to align with these goals to remain competitive and relevant.

The Future Outlook

Looking ahead, air control valve manufacturers are poised for continued growth and innovation. As industries increasingly prioritize efficiency and sustainability, the demand for advanced valve solutions is expected to rise. Manufacturers that embrace cutting-edge technologies and sustainable practices will not only enhance their market position but also contribute positively to global efforts aimed at reducing environmental impact.

In conclusion, air control valves are integral components in various systems, and the manufacturers behind them are adapting to meet modern challenges. Through innovation, sustainability, and the incorporation of smart technologies, these manufacturers are setting the stage for a more efficient and eco-friendly future. As the industry evolves, stakeholders must remain agile and responsive to changes in technology and consumer preferences, ensuring the continued success of air control valves in the marketplace.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025