Dimensions of ANSI Slip-On Flanges for Piping Applications

Understanding ANSI Slip-On Flange Dimensions

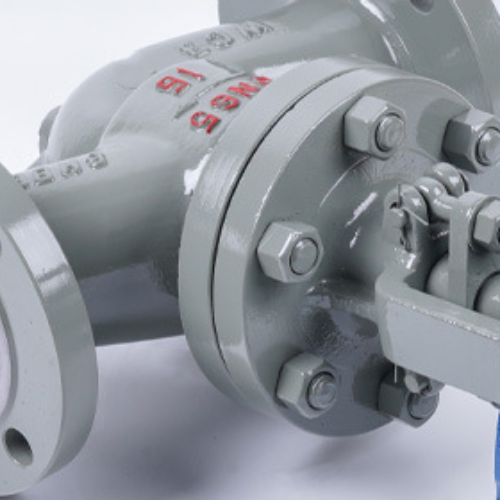

Flanges are critical components in piping systems, serving as connectors between pipes, valves, and other equipment. Among the various types of flanges, the ANSI slip-on flange is commonly used due to its simple design, ease of installation, and versatility in various applications. This article elaborates on the ANSI slip-on flange dimensions, highlighting the importance of understanding these specifications for effective piping design and installation.

What is an ANSI Slip-On Flange?

The ANSI slip-on flange is designed to slide over the ends of the connected pipes. This type of flange is particularly popular because of its ease of alignment and the straightforward welding process involved. When the connecting pipe is brought into position, the flange can be slid onto its end and then welded in place, both on the outer surface and the inside. This design allows for quick assembly while maintaining a strong and reliable connection.

ANSI Standards for Slip-On Flanges

The dimensions of slip-on flanges are guided by the American National Standards Institute (ANSI) standards, primarily ANSI B16.5, which outlines the specifications for pipe flanges and flanged fittings. This standard defines various aspects of flanges, including the pressure classes, dimensions, and tolerances relevant to their application in industrial piping.

Key Dimensions of ANSI Slip-On Flanges

1. Nominal Pipe Size (NPS) Slip-on flanges come in various nominal sizes ranging from ½ inch to 24 inches and larger. The NPS is a crucial measurement, as it determines the size of the flange to be matched with a corresponding pipe.

ansi slip on flange dimensions

2. Outer Diameter (OD) Each size of ANSI slip-on flange is associated with a specific outer diameter, which is crucial for ensuring compatibility with the piping system and preventing leaks. The outer diameter typically increases with the nominal pipe size.

3. Thickness The thickness of the slip-on flange varies based on the pressure class (e.g., 150, 300, 600, 900, etc.). Thicker flanges can withstand higher pressures, but this dimension must be chosen carefully to match the system's requirements.

4. Bore Diameter The bore diameter is the internal diameter of the flange, which matches the outer diameter of the pipe it connects. Accurate bore measurements are essential to ensure a tight fit and prevent flow obstructions.

5. Bolt Hole Diameter and Spacing ANSI slip-on flanges are equipped with bolt holes for secure fastening. The diameter of these holes and their spacing is standardized, allowing for uniformity and compatibility with bolt patterns on flanges of similar sizes.

6. Face Type ANSI slip-on flanges can have different face types, including flat face (FF), raised face (RF), and ring-type joint (RTJ). The choice of face type impacts the sealing capability and, subsequently, the overall performance of the piping system.

Conclusion

Understanding the dimensions of ANSI slip-on flanges is essential for engineers, designers, and maintenance professionals involved in piping system installations. Selecting the right size, pressure class, and dimensions ensures not only the structural integrity of the system but also its efficiency and safety. When specifying ANSI slip-on flanges, it is imperative to consult ANSI standards and consider factors such as the type of application, fluid characteristics, and environmental conditions to optimize performance.

In summary, the ANSI slip-on flange is a reliable component within the piping industry, and an in-depth understanding of its dimensions forms the foundation for effective design and implementation. Proper assessment and selection of these flanges will lead to reduced downtime and enhanced efficiency in operational processes.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025