ball valve for nitrogen gas

Understanding Ball Valves for Nitrogen Gas Applications

When it comes to the control of gases in various industrial applications, ball valves have emerged as one of the most effective and reliable solutions. Specifically designed ball valves for nitrogen gas are crucial in several sectors, including chemical processing, food packaging, and even in the aerospace industry. In this article, we delve into the characteristics, advantages, and applications of ball valves suited for nitrogen gas.

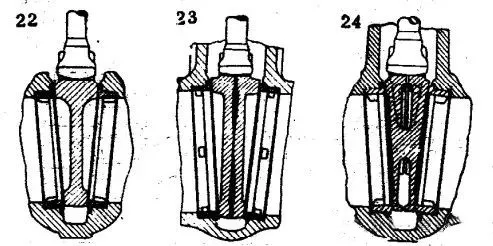

What is a Ball Valve?

A ball valve is a type of quarter-turn valve that utilizes a hollow, perforated, and pivoting ball to control the flow of liquids or gases. The ball valve is closed when the ball's solid side blocks the path of the flow, and it is opened when the ball is rotated a quarter turn, allowing fluid to flow through the valve.

Importance of Choosing the Right Valve for Nitrogen Gas

Nitrogen is an inert gas with numerous applications, including use as a purging agent, in controlled atmospheres, and as a blanketing agent to prevent oxidation. Given that nitrogen is non-reactive under normal conditions, it requires specially designed valves that ensure safety and efficiency in operations. Selecting the right ball valve for nitrogen applications is vital for maintaining pressure and preventing leaks, which is crucial for operational integrity.

Key Features of Ball Valves for Nitrogen Gas

1. Material Compatibility Ball valves must be constructed from materials that can endure nitrogen's specific environmental conditions. Common materials include stainless steel, brass, and PVC, each offering varying degrees of resistance to corrosion and temperature fluctuations.

2. Pressure Ratings Nitrogen gas applications often involve high-pressure systems. Therefore, ball valves should be rated appropriately for these conditions. Valves with high-pressure ratings assure users of their capability to handle demanding workloads without risk of failure.

ball valve for nitrogen gas

3. Sealing Mechanism The sealing mechanism within the ball valve plays a critical role in ensuring zero leakage. PTFE (Polytetrafluoroethylene) or other resilient materials are commonly used for seals, providing durability and resistance to the extreme conditions often encountered with gas applications.

4. Operating Temperature Range It’s also essential for the selected ball valve to operate efficiently within the required temperature range. Extreme temperatures could impact the valve's performance and lifespan; therefore, options with appropriate temperature ratings should be considered.

Advantages of Using Ball Valves for Nitrogen Gas

- Quick Operation Ball valves provide quick shutoff capabilities, making them ideal for emergency situations where immediate response is necessary. - Minimal Pressure Drop Due to their design, ball valves maintain a low pressure drop, ensuring efficient gas flow and reducing energy costs associated with pumping nitrogen.

- Long Lifespan With fewer moving parts and robust materials, ball valves are known for their longevity, leading to reduced maintenance and replacement costs over time.

- Versatility These valves can be used in a variety of settings, from industrial applications to specialized laboratory environments, making them an adaptable choice for many users.

Conclusion

In summary, ball valves designed for nitrogen gas applications offer a combination of reliability, efficiency, and safety. By understanding the key features required for effective nitrogen gas handling, industries can better select the appropriate ball valves, ensuring seamless operations and enhanced safety in their gas management practices. Whether in manufacturing, packaging, or laboratory settings, the right ball valve can make all the difference in operational success.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025