butterfly valve price

Understanding Butterfly Valve Prices A Comprehensive Guide

Butterfly valves are a popular choice in various industries for their simplicity, reliability, and efficiency in controlling fluid flow. These valves consist of a rotating disc that regulates flow through a pipe, providing quick and easy control. Given their widespread use, understanding the factors that influence butterfly valve prices is essential for both buyers and engineers who are involved in purchasing these components for their operations.

One of the primary factors affecting the price of butterfly valves is the type of material used in their construction. Common materials include cast iron, stainless steel, and PVC. Each material has unique properties that make them suitable for specific applications. For instance, stainless steel valves are often more expensive due to their superior corrosion resistance and ability to withstand higher temperatures and pressures. Conversely, PVC valves tend to be less costly but may not meet the demands of high-pressure or high-temperature applications.

Another significant aspect influencing butterfly valve prices is the size of the valve. Generally, larger valves come with a higher price tag due to the increased amount of material and energy required for production. Additionally, larger valves may necessitate more intricate designs or additional components, further contributing to their cost. Therefore, when evaluating pricing, it is crucial to assess the specific size requirements of your project.

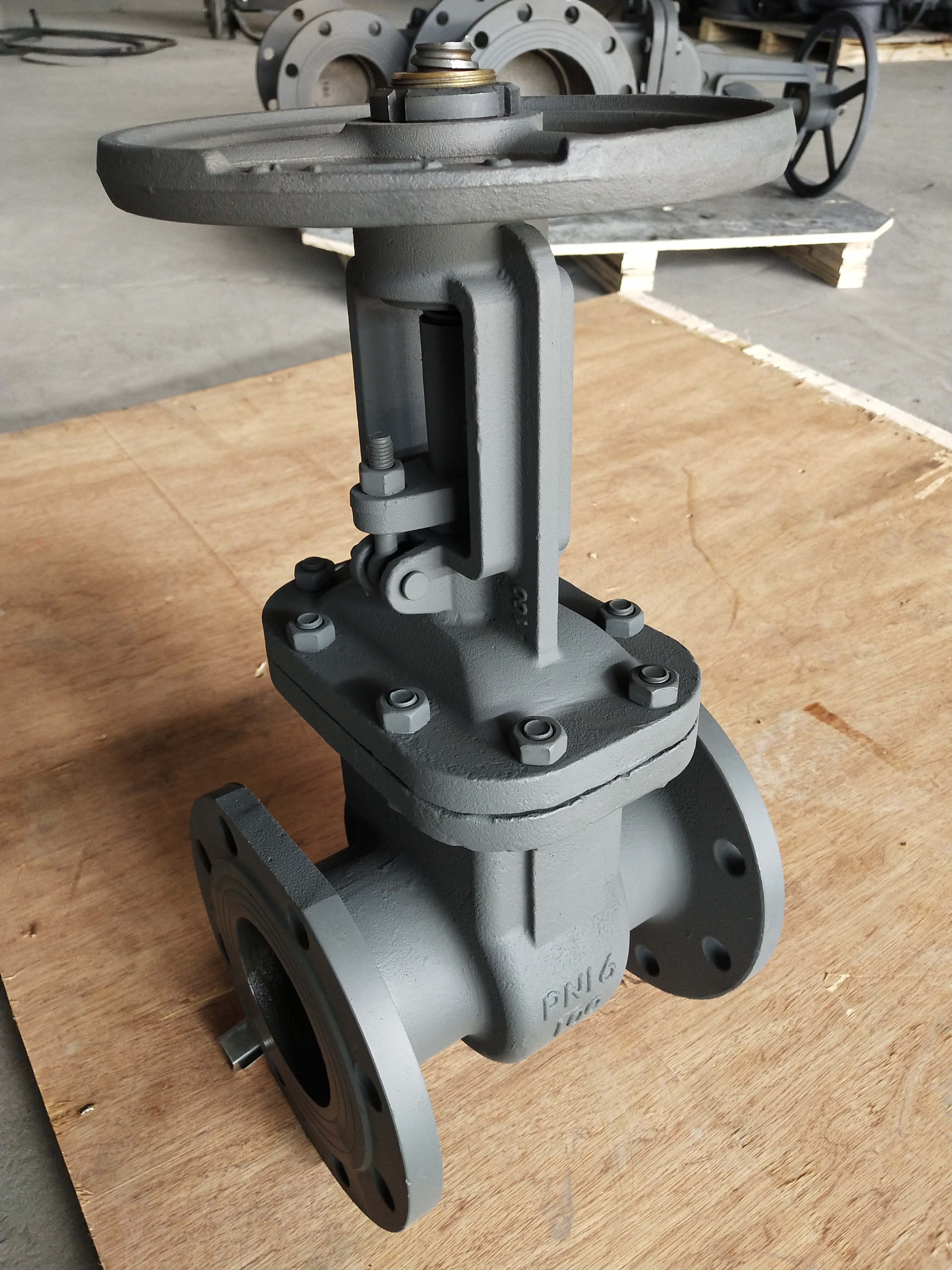

The design intricacies of butterfly valves also play a pivotal role in determining their price. There are various configurations available, such as wafer, lug, and flanged designs. Each design serves different installation requirements and can vary significantly in cost. Furthermore, the valve's pressure rating, which indicates its ability to withstand certain pressure levels, can also affect the overall price. Higher-rated valves typically feature more robust materials and construction techniques, leading to increased manufacturing costs.

butterfly valve price

In addition to these factors, the brand and manufacturer also influence pricing. Established brands with a proven track record may command higher prices due to their reputation for quality and reliability. On the other hand, lesser-known manufacturers might offer more competitive prices but could lack the same warranty or customer support. It is crucial to balance cost with quality; while opting for a cheaper option may save money upfront, it could lead to higher maintenance costs or premature failure in the long run.

Another consideration is the market demand and economic factors. The costs associated with raw materials, production, and distribution can fluctuate based on supply and demand dynamics. For instance, if there is a surge in construction or industrial activities, the demand for butterfly valves may increase, leading to price hikes. Conversely, a slowdown in these sectors can result in lower prices as manufacturers attempt to boost sales. Keeping an eye on market trends can help buyers make informed purchasing decisions.

Lastly, the inclusion of additional features can impact valve prices. For instance, options like automated actuators for remote control or specialized coatings for enhanced corrosion resistance can add significant costs. Buyers should assess whether such features are essential for their applications or if a standard butterfly valve would suffice.

In conclusion, the price of butterfly valves is influenced by a multitude of factors, including material composition, size, design, brand reputation, and market dynamics. When purchasing butterfly valves, it is vital to evaluate the specific needs of your application and weigh the long-term benefits against the initial costs. By understanding these elements, buyers can make informed decisions, ensuring they select the right valves for their projects without compromising quality or budget. Whether for water treatment, HVAC systems, or chemical processing, a well-chosen butterfly valve can contribute significantly to operational efficiency and reliability.

-

Premium Gas Ball Valves: Safe & Reliable Flow ControlNewsAug.31,2025

-

High-Security Lockable Gas Valve - Tamper-Proof ControlNewsAug.30,2025

-

Reliable Hydraulic Valves for Efficient Fluid ControlNewsAug.29,2025

-

Reliable Electric Actuators for Industrial Valve AutomationNewsAug.29,2025

-

Premium Line Blind Valves for Secure Pipeline IsolationNewsAug.29,2025

-

Premium Electric Valves for Smart Fluid Control SolutionsNewsAug.29,2025

-

Precision Balanced Valves for Optimal System PerformanceNewsAug.29,2025