Cap Pipe Fitting Manufacturer for Reliable and Durable Plumbing Solutions

The Importance of Quality in Cap Pipe Fittings Manufacturing

In the world of plumbing and piping systems, the integrity and reliability of components play a critical role in ensuring proper functionality and safety. Among these components, cap pipe fittings—used to seal the ends of pipes—are fundamental in various applications, including residential, commercial, and industrial settings. As the demand for these products continues to rise, the importance of selecting a reputable cap pipe fitting manufacturer cannot be overstated.

Understanding Cap Pipe Fittings

Cap pipe fittings are essential for closing off the ends of pipes, preventing leaks, dirt accumulation, and other unwanted substances from entering the system. They are available in various materials, including PVC, CPVC, metal, and more, catering to different needs based on the application requirements. Whether used in water distribution, sewage systems, or chemical handling, the choice of material and quality of the manufacturing process directly impact the fitting’s durability and performance.

The Role of Quality in Manufacturing

Quality is a cornerstone of any successful manufacturing operation, especially in the production of cap pipe fittings. A high-quality product must endure significant pressure and temperature variations and resist corrosion and wear over time. Manufacturers that adhere to stringent quality control measures can ensure that their products meet industry standards and regulations. This includes using only the best raw materials, implementing precision machining techniques, and conducting rigorous testing procedures.

One aspect that embodies quality in manufacturing is the adherence to international standards such as ASME, ASTM, and ISO. These standards provide guidelines that ensure consistency and reliability across products, which is vital for installations pertaining to safety and performance. Therefore, a manufacturer that actively complies with these standards will produce cap pipe fittings that not only serve their purpose but excel in longevity and reliability.

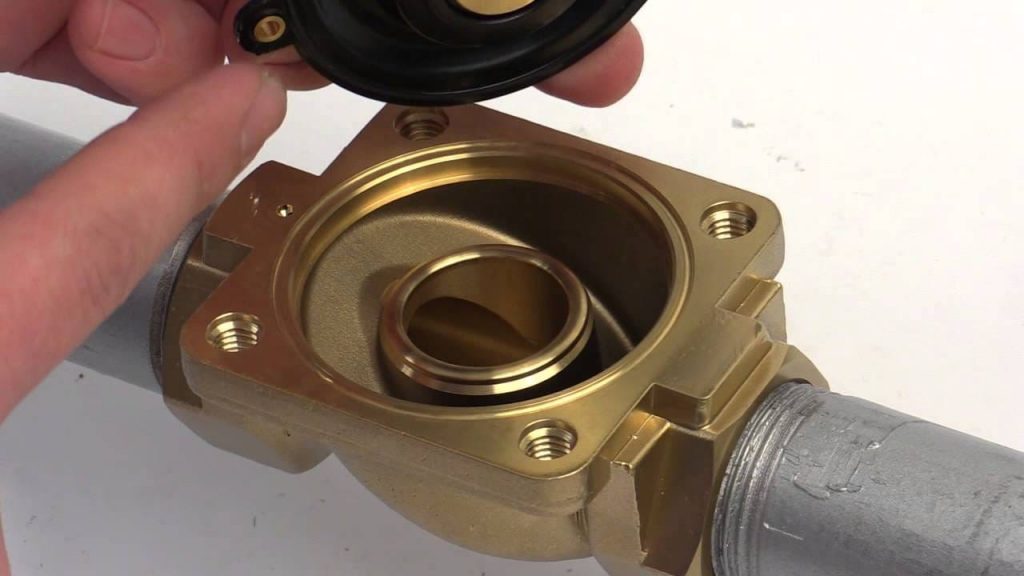

cap pipe fitting manufacturer

Economical Manufacturing Techniques

In addition to maintaining high-quality standards, efficient manufacturing processes can lead to enhanced productivity and cost-effectiveness. Many modern manufacturers utilize advanced technologies such as computerized numerical control (CNC) machining, 3D printing, and automation, which optimize the manufacturing workflow. These technologies allow for precise cuts, minimized material wastage, and consistent output, ultimately reducing production costs without compromising quality.

Supplier Reliability and Reputation

Choosing a trusted cap pipe fitting manufacturer is crucial for businesses and contractors who need dependable components for their projects. Manufacturers with a solid reputation often have a history of delivering high-quality products on time while providing excellent customer service. Reliable suppliers understand the necessity of not just providing a product, but also building long-term relationships with their clients. This fosters open communication, allowing customers to receive personalized solutions and support as needed.

Conclusion

In summary, the selection of a cap pipe fitting manufacturer is a significant decision that can impact the efficiency and safety of piping systems. By focusing on quality, adherence to industry standards, economical production techniques, and reliable service, manufacturers can deliver cap pipe fittings that meet the diverse needs of their clientele. As industries continue to evolve and grow, so too will the technologies and standards that govern this essential sector—making it ever more imperative to choose a capable partner in the realm of pipe fitting manufacturing. Whether for a small home renovation or a large-scale industrial project, ensuring that you invest in quality cap pipe fittings is an investment in reliability and peace of mind.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025