Top Manufacturers of Cast Iron Butterfly Valves for Industrial Applications

The Role of Cast Iron Butterfly Valve Manufacturers in Modern Industry

Butterfly valves are essential components in various industrial applications, renowned for their simple design and efficient operation. Among the many materials used in their construction, cast iron has emerged as a popular choice due to its durability and resistance to wear and corrosion. This article explores the significance of cast iron butterfly valve manufacturers in modern industry, their manufacturing processes, and the advantages of their products.

What are Butterfly Valves?

Butterfly valves are quarter-turn valves that utilize a rotating disc to regulate fluid flow. The simplicity of their design allows for quick operation, making them suitable for applications ranging from water supply and sewage treatment to gas pipelines and chemical processing. When it comes to selecting materials, cast iron stands out for its strength, longevity, and cost-effectiveness.

The Manufacturing Process

The manufacturing of cast iron butterfly valves involves several critical steps. These include mold making, casting, machining, and finishing.

1. Mold Making This initial stage involves creating a mold that determines the shape and dimensions of the valve. Manufacturers typically use advanced computer-aided design (CAD) software to design precise molds that meet industry standards.

2. Casting In this step, molten cast iron is poured into the prepared molds. The casting process can vary, with methods such as sand casting or investment casting being employed based on the desired final properties of the valve. Once cooled, the cast iron takes on the required shape.

3. Machining After casting, the valves undergo machining to achieve the precise dimensions and smooth finishes necessary for optimal performance. This step may involve processes like drilling, turning, and grinding.

4. Finishing The final step includes surface treatments such as painting or coating to enhance corrosion resistance. Manufacturers may also conduct rigorous testing to ensure the valves meet quality standards before they reach the market.

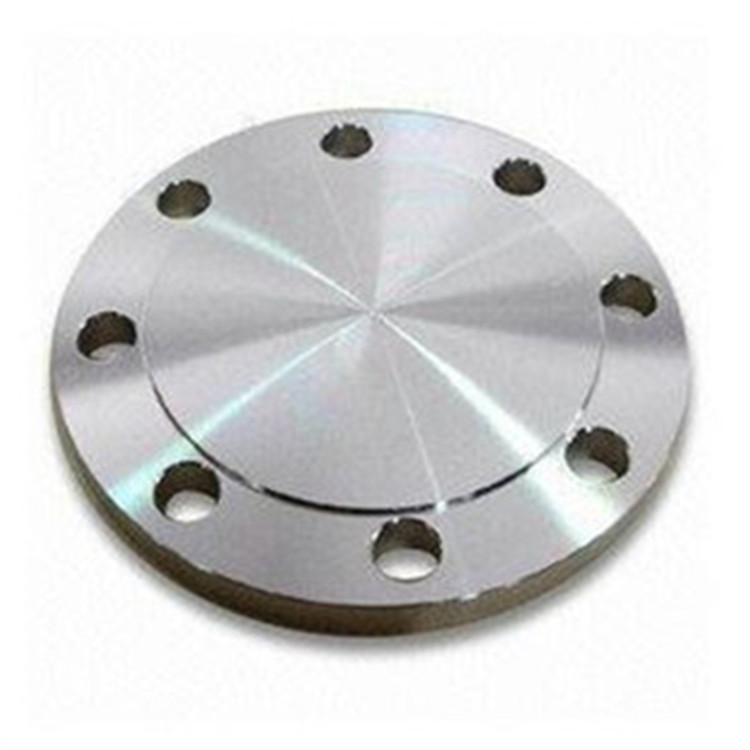

cast iron butterfly valve manufacturers

Advantages of Cast Iron Butterfly Valves

1. Durability Cast iron is known for its robustness and ability to withstand high pressures and temperatures. This makes cast iron butterfly valves suitable for a variety of harsh environments.

2. Cost-Effectiveness Compared to other materials such as stainless steel or bronze, cast iron is more affordable, making it an attractive option for industries looking to balance quality and budget.

3. Versatility Cast iron butterfly valves can handle various fluids, including water, chemicals, and gases, making them highly versatile for different applications.

4. Easy Maintenance The straightforward design of these valves facilitates easy maintenance and repair, ensuring prolonged service life with minimal downtime.

The Competitive Landscape

The market for cast iron butterfly valve manufacturers is competitive, with numerous companies vying for market share. Manufacturers must differentiate themselves through innovation, quality control, and customer service. Many companies are adopting advanced technologies, such as automation and robotics, to enhance production efficiency while maintaining high-quality standards. Additionally, some manufacturers focus on sustainability by implementing eco-friendly practices in their operations.

Conclusion

Cast iron butterfly valve manufacturers play a crucial role in modern industry. Their products are integral to the effective management of fluid flow in diverse applications, from municipal water systems to heavy industrial processes. As industries continue to evolve, the demand for reliable, durable, and cost-effective solutions like cast iron butterfly valves is set to grow. Manufacturers that prioritize quality, innovation, and customer satisfaction will likely lead the way in this ever-changing market. Investing in cast iron butterfly valves not only ensures efficient operations but also contributes to the overall sustainability of industrial practices.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025