Similar Specifications for China Class 150 Gate Valve Design and Features

Understanding China Class 150 Gate Valves

Gate valves are essential components in the pipeline system, widely used in water supply, oil, and gas industries. Among various classifications and standards, the China Class 150 gate valve stands out due to its widespread application and reliability. In this article, we will explore the characteristics, applications, and advantages of China Class 150 gate valves.

What is a Class 150 Gate Valve?

The term Class 150 refers to the pressure rating of the valve, which is defined by the American National Standards Institute (ANSI). It signifies that the valve is designed to operate safely within a specific pressure range, typically up to 150 psi (pounds per square inch) at a standard temperature of 100°F. In and beyond China, the Class designation helps classify valves based on their pressure-handling capabilities, ensuring that they are suitable for their intended applications.

Characteristics of China Class 150 Gate Valves

1. Material Construction China Class 150 gate valves are typically constructed from durable materials like cast iron, ductile iron, carbon steel, or stainless steel. The choice of material depends on the application and the fluid being transported through the pipeline.

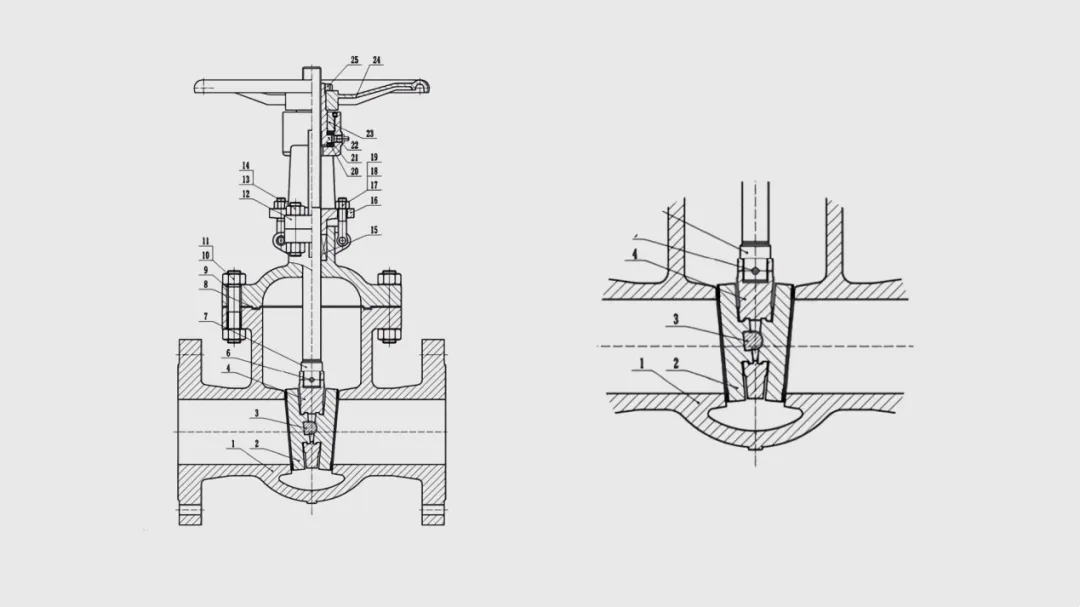

2. Design Most Class 150 gate valves feature a wedge-shaped gate that moves vertically within the valve body. The design allows for minimal pressure drop when the valve is fully opened and provides a tight seal when closed, preventing leaks.

3. Size Range These valves are available in various sizes, typically ranging from ½ inch to 24 inches in diameter. This size flexibility makes them suitable for a broad range of pipelines.

4. Operating Mechanism The gate valve can be operated using a manual handwheel, electric actuator, or hydraulic actuator, depending on the specific needs of the application. Manual operation is common for smaller valves, while larger valves may require automated systems for efficient operation.

Applications of China Class 150 Gate Valves

The versatility of China Class 150 gate valves allows their use in various applications, including

china class 150 gate valve

1. Water Supply Systems In municipal water systems, gate valves regulate water flow and are integral to shutting down sections for maintenance or emergencies.

2. Oil and Gas Pipelines These valves are crucial in both upstream and downstream processes in the oil and gas industry, allowing operators to manage flow effectively and safely.

3. Chemical Processing They are also used in chemical plants to control the flow of corrosive fluids, ensuring safety and efficiency in industrial processes.

4. HVAC Systems In heating, ventilation, and air conditioning systems, gate valves play a critical role in managing the flow of water or steam.

Advantages of China Class 150 Gate Valves

1. Low Resistance to Flow When fully opened, gate valves offer minimal turbulence and pressure drop, making them highly efficient for controlling fluid flow.

2. Reliable Seal The design of the wedge-shaped gate ensures that when the valve is closed, a tight seal is achieved, preventing leaks and maintaining system integrity.

3. Ease of Maintenance Compared to other types of valves, gate valves are generally easier to maintain and repair, which reduces downtime and operational costs.

4. Durability Constructed with robust materials, Class 150 gate valves are designed to withstand harsh operating conditions, ensuring a long lifespan.

Conclusion

In summary, China Class 150 gate valves are vital components in various industrial applications due to their reliability, efficiency, and ease of maintenance. Whether in water supply systems, oil and gas pipelines, or chemical processing plants, these valves effectively manage fluid flow and ensure operational integrity. As industries continue to evolve, the importance of durable and efficient gate valves will remain paramount in maintaining effective and safe operations.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025