China's Role in Global Globe Valve Market Dynamics and Trends

Understanding China’s Control Globe Valves A Comprehensive Overview

Control globe valves are integral components in various industrial applications, facilitating the regulation of fluid flow. In China, the production and utilization of these valves have witnessed significant growth as industries strive for efficiency and reliability in their operations. This article delves into the characteristics, applications, and advantages of control globe valves, particularly within the Chinese context.

What Are Control Globe Valves?

Control globe valves are designed to manage the flow of liquids and gases in piping systems. They feature a spherical body shape with an internal baffle that allows for varied adjustments of flow rate. The valve is categorized based on its application, with variations including standard globe valves, pressure-reducing valves, and automated control valves. The fundamental principle of operation involves a movable disc that alters the flow path's size, enabling precise control over the medium's velocity and pressure.

Key Characteristics

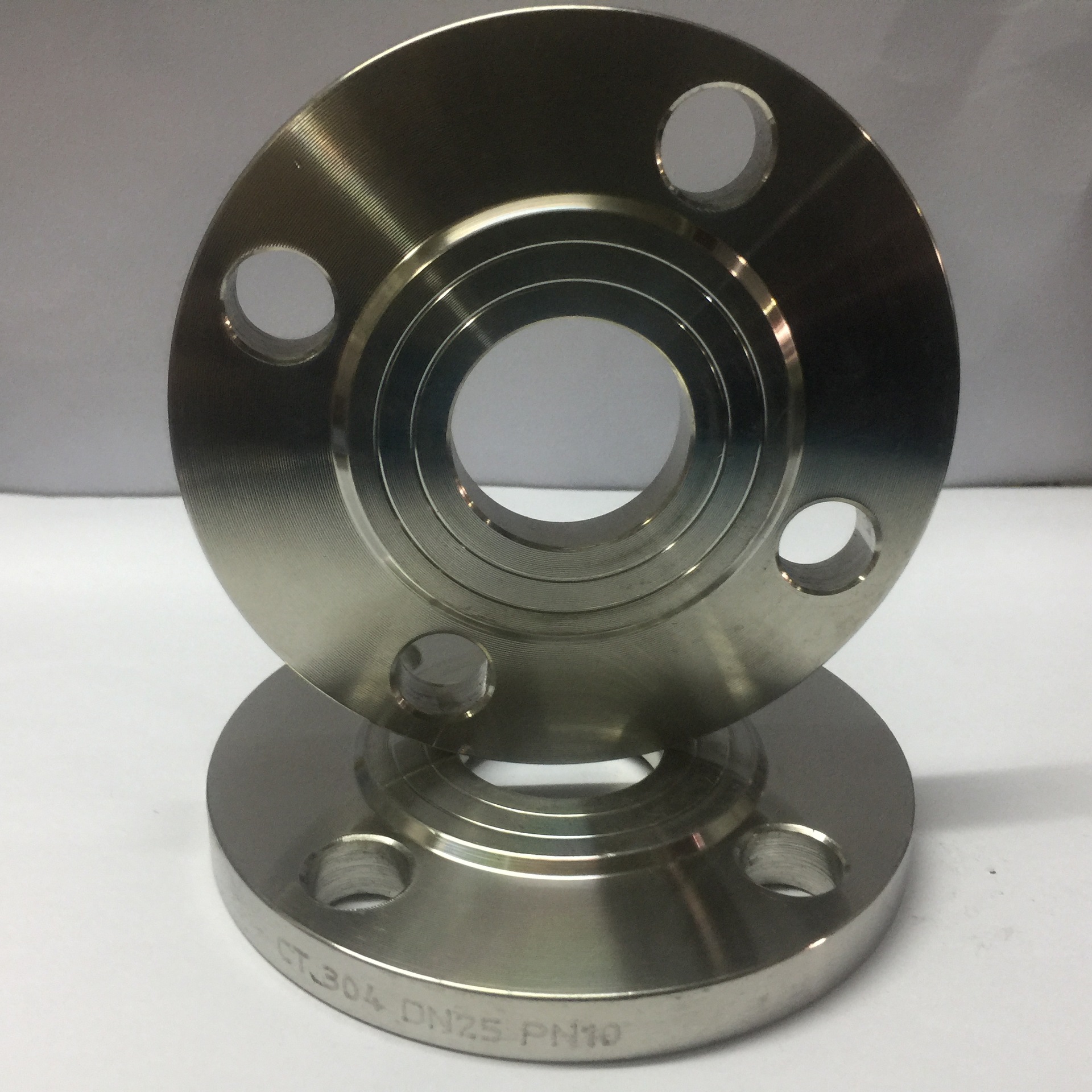

1. Design and Construction Control globe valves are typically constructed from materials such as stainless steel, carbon steel, and brass. This ensures they can withstand harsh environments, high pressures, and temperature fluctuations.

2. Flow Control Mechanism The internal design allows for throttling, which means they can efficiently control flow rates, making them an essential component in systems where precise measurements and adjustments are crucial.

3. Versatility They can be fitted with actuators for automatic operations, making them suitable for modern automated systems prevalent in industries such as oil and gas, water treatment, and chemical production.

Applications in Various Industries

In China, control globe valves are widely utilized across numerous sectors

- Oil and Gas In refining and distribution processes, these valves ensure accurate flow control of volatile materials, contributing to operational safety and efficiency.

china control globe valve

- Water Management Control globe valves play a vital role in regulating water flow in treatment plants and distribution systems, ensuring that water quality and pressure are maintained at optimal levels

.- Chemical Industry In processes involving corrosive chemicals, these valves provide essential control, safeguarding both the integrity of the piping and the overall safety of the operations.

- HVAC Systems Control globe valves are integral in heating, ventilation, and air conditioning systems, allowing for the regulation of coolant flow, thus enhancing energy efficiency.

Advantages of Control Globe Valves

1. Precision in Flow Regulation One of the primary advantages of control globe valves is their ability to provide precise control over fluid flow, which is essential in many industrial processes.

2. Robust Construction Their durable construction enhances longevity, reducing the frequency of replacements and maintenance, which is particularly beneficial in large-scale operations.

3. Ease of Automation The compatibility of control globe valves with various actuator types allows for their integration into automatic control systems, facilitating modern production methodologies.

4. Wide Range of Applications Their versatility makes them suitable for a broad spectrum of industries, from heavy manufacturing to municipal services.

Conclusion

Control globe valves represent a crucial aspect of fluid management in industrial processes, especially in China, where the demand for efficient and reliable systems is ever-increasing. Understanding their features, applications, and benefits underscores their importance in not only improving operational efficiency but also in meeting safety and regulatory standards. As China continues to advance its industrial capabilities, the role of control globe valves is poised to grow, making them a significant element in the future of engineering and manufacturing in the region.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025