Ductile Iron Gate Valve for Efficient Water Control Systems in China

Understanding China Gate Valve in Ductile Iron A Comprehensive Overview

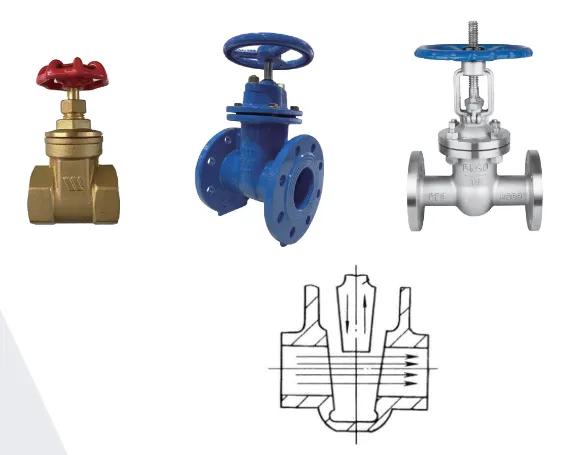

Gate valves are a pivotal component in the world of fluid control, extensively utilized across various sectors including water supply, oil and gas, and industrial processes. Among the types of gate valves available, ductile iron gate valves stand out for their durability, reliability, and versatile application. This article explores the features, advantages, and applications of China-manufactured ductile iron gate valves.

What is a Gate Valve?

A gate valve is a type of valve that opens by lifting a rectangular or round gate out of the path of the fluid. The primary function of a gate valve is to allow or prevent the flow of fluids in pipelines. When fully opened, a gate valve offers minimal fluid resistance, making it highly efficient for fluid flow management.

Ductile Iron The Material Choice

Ductile iron, also known as spheroidal graphite iron, is an alloy of iron that incorporates carbon in a specific form that enhances its mechanical properties. Compared to traditional cast iron, ductile iron boasts higher strength, improved ductility, and better enamel adhesion. These attributes make it an excellent choice for manufacturing heavy-duty gate valves that can withstand high pressure and extreme temperatures.

Advantages of Using Ductile Iron Gate Valves from China

1. Durability and Strength Ductile iron gate valves are robust and can handle significant pressure and temperature fluctuations. This durability ensures a longer lifespan, reducing the need for frequent replacements and maintenance.

2. Corrosion Resistance Enhanced protection against rust and corrosion is a notable feature of ductile iron. Many manufacturers apply protective coatings to resist environmental factors, ensuring that these valves remain functional over time.

china gate valve ductile iron

3. Cost-Effectiveness Chinese manufacturers often provide ductile iron gate valves at competitive prices without compromising on quality. This affordability has made them a popular choice in global markets.

4. Wide Range of Applications Ductile iron gate valves are versatile and find use in numerous applications, including potable water distribution, wastewater management, fire protection systems, and industrial processes. Their capacity to handle diverse fluid types makes them indispensable.

5. Ease of Operation Gate valves typically feature a handwheel or actuator for smooth operation. This simplicity allows for efficient control over fluid flow, facilitating quick open and close actions.

Key Features to Consider

When selecting a ductile iron gate valve, it’s essential to consider several factors

- Size and Pressure Rating Ductile iron gate valves come in various sizes and pressure ratings. Ensure that the chosen valve aligns with the specifications of your system. - End Connections Different end connections (flanged, threaded, or welded) are available, which should match the configuration of your existing pipeline.

- Standards and Certifications Look for valves that adhere to international standards such as ANSI, API, or ISO. Certifications indicate that the valves meet specific performance criteria.

Conclusion

The ductile iron gate valve, especially those manufactured in China, offers a balance of quality, durability, and cost-effectiveness. As industries increasingly rely on reliable fluid control solutions, the importance of choosing the right gate valve cannot be overstated. By considering the advantages and key features of ductile iron gate valves, businesses can make informed decisions that enhance operational efficiency and reliability in fluid management systems. With continued advancements in manufacturing and technology, these valves are likely to remain a preferred choice for fluid control applications across various sectors.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025