High Efficiency Butterfly Valve Solutions for the Chinese Market

High-Performance Butterfly Valves in China A Comprehensive Overview

Butterfly valves are critical components in numerous industrial applications, particularly in fluid control systems. These valves are known for their simplicity, lightweight design, and ability to handle a vast range of liquids and gases. In recent years, China has emerged as a leader in the manufacturing and development of high-performance butterfly valves, catering to both domestic and international markets.

Understanding Butterfly Valves

A butterfly valve consists of a rotating disc that regulates the flow of fluid through a pipe. When the valve is fully opened, the disc is positioned parallel to the flow, allowing maximum flow with minimal resistance. Conversely, when closed, the disc turns to a perpendicular position, effectively blocking the passage of the medium. The straightforward mechanism employed by butterfly valves makes them an ideal choice for various conditions, including high-pressure and high-temperature scenarios.

Advancements in Design and Engineering

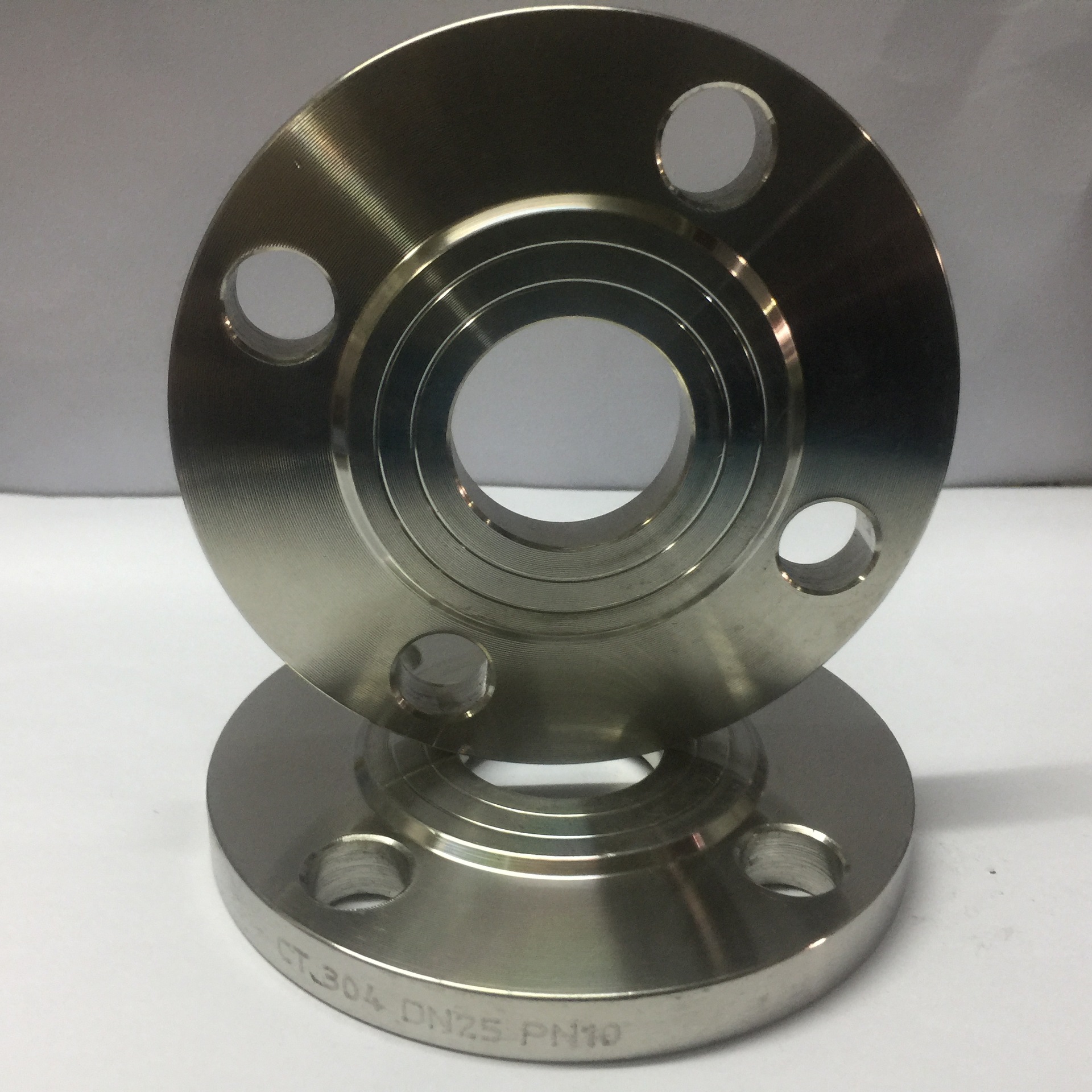

Chinese manufacturers have leveraged advancements in technology to enhance the performance and efficiency of butterfly valves. These advancements include improvements in material quality, aerodynamic design, and sealing mechanisms. High-performance butterfly valves are often constructed from durable materials such as stainless steel, carbon steel, and special alloy fabrics, which contribute to their longevity and reliability in harsh environments.

Moreover, the development of advanced engineering techniques has led to the production of valves that can withstand extreme conditions. This includes the ability to resist corrosion, erosion, and temperature fluctuations, which are common in many industrial processes. As a result, high-performance butterfly valves from China find applications in petrochemical, power generation, water treatment, and HVAC systems.

Customization and Versatility

china high performance butterfly valve

One of the critical strengths of China's high-performance butterfly valves is the ability to customize them according to specific operational requirements. Manufacturers understand that industries have distinct needs, and as such, they offer a range of sizes, materials, and configurations. Whether it’s toward achieving optimal flow rates, meeting regulatory standards, or fitting specific installation space constraints, the versatility of these valves makes them indispensable in various sectors.

Furthermore, the capability of Chinese manufacturers to offer competitive pricing without sacrificing quality has positioned them as formidable players in the global market. This value proposition has attracted international customers seeking reliable performance at economical rates.

Innovative Manufacturing Processes

The manufacturing processes adopted by Chinese valve producers are continuously evolving. Companies are investing in automation and digital technologies to improve production efficiency and quality control. Advanced machining techniques, such as CNC (Computer Numerical Control), allow for precision fabrication, resulting in tighter tolerances and superior fit and finish.

Additionally, sustainable practices are being integrated into manufacturing processes. Many producers are focusing on reducing waste and energy consumption, aligning with global trends towards environmental responsibility. This commitment not only enhances product quality but also contributes to the wider fight against climate change.

Market Trends and Future Outlook

The demand for high-performance butterfly valves is expected to grow further, driven by increased infrastructure development, industrialization, and the need for energy-efficient solutions. China’s investments in research and development will likely yield innovative designs that enhance the functionality and applicability of butterfly valves across various sectors.

In conclusion, the evolution of high-performance butterfly valves in China represents a synthesis of traditional engineering principles and modern technological advancements. As industries continue to seek efficient and reliable flow control solutions, Chinese manufacturers are well-positioned to meet this demand with high-quality, customizable, and cost-effective products. The future of butterfly valves in China looks promising, paving the way for continued growth and innovation in this vital sector.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025