China's Stainless Steel Check Valve Solutions for Various Applications and Industries

Understanding Stainless Steel Check Valves in China

In the landscape of industrial components, check valves play a crucial role in maintaining the integrity of fluid systems. Among these, stainless steel check valves have emerged as a preferred choice due to their durability, corrosion resistance, and reliability. In China, a leading manufacturer and supplier of various industrial components, stainless steel check valves are in high demand across multiple sectors.

What is a Check Valve?

A check valve, also known as a non-return valve, is a device that allows fluid to flow through it in one direction while preventing backflow. This mechanism helps protect equipment and pipelines from damage that can occur when fluids flow in the opposite direction. Check valves are essential in applications such as water and waste management, oil and gas, and chemical processing.

Benefits of Stainless Steel Check Valves

1. Corrosion Resistance One of the foremost advantages of stainless steel is its inherent resistance to corrosion, which is particularly valuable in environments where rust and decay could compromise performance. This property extends the lifespan of the valve, making it a cost-effective solution in the long run.

2. High Temperature and Wear Resistance Stainless steel can withstand higher temperatures compared to many other materials, making it suitable for applications that involve heat and pressure. Additionally, its wear resistance contributes to reduced maintenance needs, further enhancing operational efficiency.

3. Hygienic Properties For industries such as food and beverage, pharmaceuticals, and healthcare, stainless steel check valves offer a hygienic solution as they can be easily cleaned and sanitized, thus ensuring that contamination is minimized.

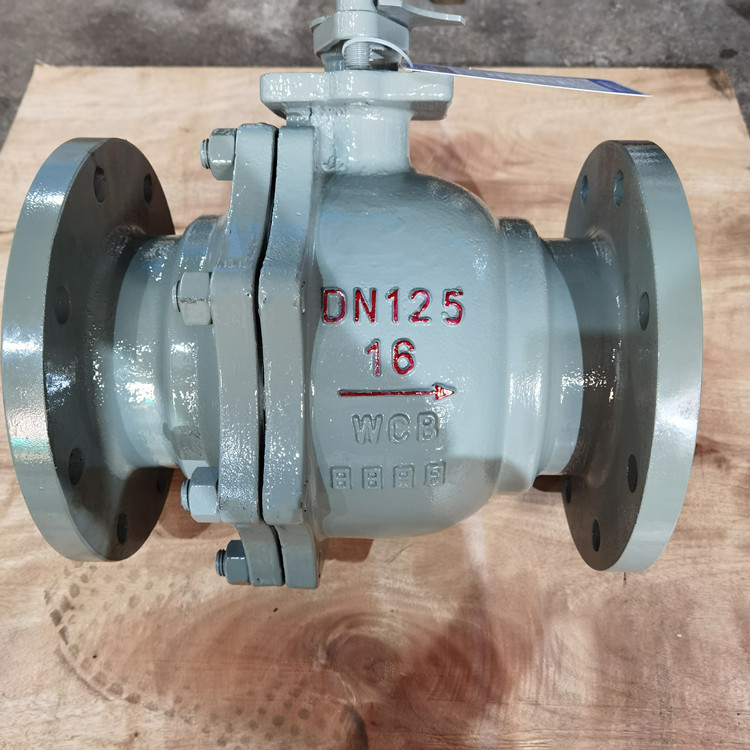

china check valve stainless steel

4. Versatility Stainless steel check valves can be designed for different applications and are available in various sizes and configurations. This versatility allows manufacturers to tailor solutions that meet specific operational requirements.

The Manufacturing Landscape in China

China has established itself as a global hub for manufacturing, including the production of stainless steel check valves. Numerous companies specialize in developing high-quality valves that comply with international standards. Many of these manufacturers implement advanced technologies and rigorous quality control processes, resulting in products that meet or exceed customer expectations.

Environmental Considerations

As global awareness of environmental issues rises, manufacturers in China are increasingly mindful of sustainability. Many companies are adopting eco-friendly practices during the production of stainless steel check valves, including efficient resource management and reducing waste. This commitment not only helps protect the environment but also appeals to an expanding market of environmentally conscious consumers.

Conclusion

In summary, stainless steel check valves are indispensable components in various industries, renowned for their durability, resistance to corrosion, and efficiency. China's manufacturing sector has adeptly positioned itself to meet the growing demand for high-quality valves, contributing to the global supply chain. As industries continue to evolve and seek innovative solutions, the role of stainless steel check valves in ensuring operational reliability will remain significant. The combination of advanced manufacturing techniques and a focus on quality ensures that these products will continue to be a fundamental part of fluid dynamics in a wide array of applications.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025