china split butterfly valve

Understanding the China Split Butterfly Valve

The split butterfly valve is an essential component in many industrial processes, particularly in the sectors of water management, chemical processing, and HVAC systems. In recent years, China has become a significant player in the manufacturing and supply of these valves, driven by the growth of its economy and infrastructure development.

What is a Split Butterfly Valve?

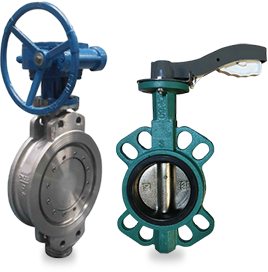

A split butterfly valve is characterized by its unique design, which features two halves of a disc that can pivot to control the flow of fluid through a pipeline. This type of valve is especially effective for applications requiring a lightweight, compact solution that can provide a tight seal. The split design enables easy maintenance and replacement, making it a preferred choice in various industries.

The main components of a split butterfly valve include the body, disc, shaft, and actuator. The body is made from materials like cast iron, stainless steel, or plastic, depending on the application requirements. The disc can be constructed from various materials to withstand different types of fluids and pressures. One of the key advantages of a butterfly valve is its ability to regulate flow with minimal pressure drop, which is crucial in energy efficiency.

The Importance of Quality Manufacturing

China’s dominance in the global market for split butterfly valves is attributed to its robust manufacturing capabilities. The country has invested heavily in advanced technologies and skilled labor, facilitating the production of high-quality valves that meet international standards. Many Chinese manufacturers have also adopted ISO and API certifications to ensure the reliability and safety of their products.

china split butterfly valve

Quality control is a critical aspect of valve production. Chinese manufacturers utilize stringent testing methods to guarantee that each split butterfly valve can withstand varying pressures and temperatures. Additionally, many manufacturers implement automated processes, further enhancing the precision and consistency of their products.

Applications across Industries

The applications of split butterfly valves are broad and varied. In the water treatment sector, these valves are utilized to control the flow of water in treatment plants, ensuring efficient processing and distribution. In the oil and gas industry, they serve a vital role in maintaining the flow of crude oil and natural gas through pipelines, where reliability is paramount.

The HVAC sector also benefits from split butterfly valves, as they are often used in air handling units to regulate airflow in commercial buildings. Their ability to provide precise control over fluid dynamics makes them invaluable for maintaining efficient heating and cooling systems.

Future Trends

As industries continue to evolve, the demand for split butterfly valves is expected to rise. With the global focus on sustainable practices, manufacturers are exploring innovative materials and designs that reduce environmental impact. Furthermore, the integration of smart technologies into valve designs is anticipated, allowing for real-time monitoring and automated control systems.

In conclusion, China’s split butterfly valve industry is poised for continued growth and innovation. With a focus on quality manufacturing and adaptability to various industrial needs, these valves will remain a vital component in the advancement of various sectors worldwide. As industries strive for efficiency and sustainability, the role of split butterfly valves will undoubtedly become increasingly significant in the global market.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025