control needle valve manufacturer

The Importance of Control Needle Valve Manufacturers in Fluid Dynamics

In the realm of fluid dynamics, precise control over fluid flow is crucial for a variety of industries, including oil and gas, chemical processing, and water management. One of the key components that facilitate this control is the control needle valve. Designed to regulate the flow of fluids seamlessly, these valves play a pivotal role in ensuring system efficiency and safety. Understanding the significance of control needle valve manufacturers provides insight into their contributions to modern industrial processes.

What is a Control Needle Valve?

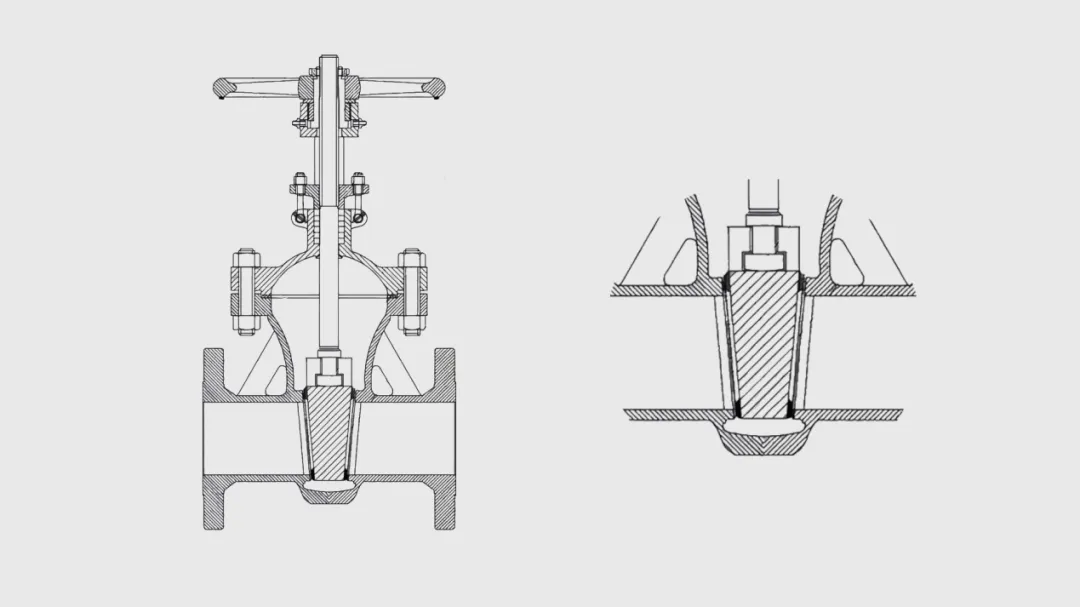

A control needle valve is a type of valve that allows for the fine-tuning of fluid flow through a pipeline. It features a tapered plug or spindle that can be adjusted by turning a handle or wheel, providing precise control over the fluid's passage. This design allows operators to vary flow rates, pressure, and even temperature, depending on the application. Control needle valves can be used in various contexts, from small-scale laboratory settings to large-scale industrial systems.

The Role of Manufacturers

Manufacturers of control needle valves play an essential role in ensuring the availability and quality of these components. Their responsibilities include

1. Design and Engineering The first step in manufacturing control needle valves involves meticulous design and engineering. This includes selecting appropriate materials that can withstand the corrosive or abrasive nature of certain fluids. Engineers must also consider factors such as pressure ratings, temperature limits, and the valve's compatibility with existing systems.

2. Quality Control Manufacturers are tasked with maintaining high-quality standards. This involves thorough testing of each valve produced to ensure that they meet industry regulations and perform reliably under various conditions. Quality control measures often include pressure testing, leak testing, and performance evaluation to confirm that each valve operates within designated specifications.

control needle valve manufacturer

3. Customization Different applications may require unique specifications. Control needle valve manufacturers often offer customization options to meet the specific demands of their clients. This could include alterations in size, material composition, and even the valve’s operational mechanism to better suit the application at hand.

4. Research and Development Continually innovating is vital for manufacturers to stay competitive. This includes investing in research and development to create more efficient, durable, and cost-effective valves. By adopting new technologies and materials, manufacturers can improve the performance of control needle valves, making them more versatile across various industries.

5. Customer Support and Service Beyond manufacturing, companies must also provide robust customer service. This includes assisting clients with installation, maintenance, and troubleshooting of control needle valves. Building strong relationships with customers ensures that manufacturers can adapt their products based on feedback and evolving industry needs.

Market Demand and Trends

The demand for control needle valves is increasing, driven by the growth of industries reliant on fluid management. The oil and gas sectors, for example, require precise flow control for safety and efficiency. Similarly, the pharmaceutical and food processing industries benefit from control needle valves for managing various liquid products.

Trends also indicate a growing need for environmentally friendly solutions. Manufacturers are responding by developing valves that minimize leaks and emissions, contributing to more sustainable operations. Additionally, the integration of smart technologies into valve systems allows for remote monitoring and automated control, enhancing operational efficiency.

Conclusion

In conclusion, control needle valve manufacturers are crucial in the fluid control landscape. They ensure the functionality, reliability, and adaptability of control needle valves across various industries, improving fluid management systems. As technology advances and industry standards evolve, these manufacturers will continue to lead the way in innovating and optimizing products to meet the demands of a changing market. By fostering quality, customization, and customer engagement, they will play an indispensable role in the future of fluid dynamics.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025