cryogenic check valve

Cryogenic Check Valve Essential Component in Low-Temperature Systems

Cryogenic check valves play a crucial role in the management and control of cryogenic fluids, which are liquefied gases at extremely low temperatures, typically below -150°C (-238°F). These valves are designed to prevent backflow in piping systems, ensuring that the flow of refrigerants and other cryogenic liquids is maintained in a one-way direction. Their functionality is vital in various applications, ranging from aerospace to medical technologies, where maintaining low temperatures is essential for preserving the integrity of materials and compounds.

Understanding Cryogenic Check Valves

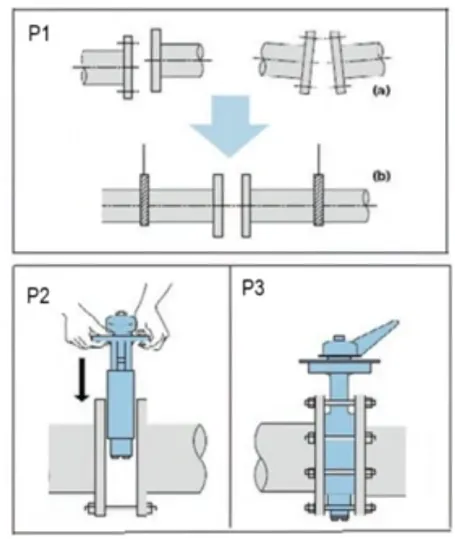

Cryogenic check valves operate by allowing fluid to flow in one direction while automatically closing to prevent backflow. This is particularly important in cryogenic applications as backflow can lead to pressure fluctuations and system failures. These valves are typically characterized by their robust design, capable of withstanding extreme temperatures and pressures inherent to cryogenic systems.

Features and Design Considerations

The materials used in cryogenic check valves are specially selected for their ability to perform at low temperatures. Common materials include stainless steel, brass, and various alloys that maintain their strength and ductility in cryogenic conditions. Additionally, manufacturers often employ specialized coatings and treatments to enhance corrosion resistance and longevity.

One key design feature of cryogenic check valves is their sealing mechanism, which ensures a tight shut-off to prevent leakage

. Two common types of sealing methods used are soft seals and metal seals. Soft seals provide excellent sealing capabilities and are often used in applications where leak-tight performance is paramount. Metal seals, while less forgiving, offer superior reliability in extreme temperature fluctuations, making them suitable for high-pressure cryogenic applications.cryogenic check valve

Applications of Cryogenic Check Valves

Cryogenic check valves are vital in a wide array of industries. In the aerospace sector, these valves are used to manage cryogenic fuels, such as liquid oxygen and liquid hydrogen, which are critical for rocket propulsion systems. By preventing backflow, these valves help maintain the efficiency and safety of the fuel supply during launch operations.

In the medical industry, cryogenic check valves are employed in applications such as cryopreservation, where biological samples and cells are stored at extremely low temperatures to preserve their viability. The integrity of the storage system relies on the reliable operation of check valves to prevent any reverse flow that could compromise the cryogenic environment.

Additionally, these valves are also found in the processing and transportation of liquefied natural gas (LNG) and other industrial gases. As LNG has become a crucial energy resource, ensuring safe and efficient transport is of paramount importance, and cryogenic check valves help achieve this by safeguarding the flow of these gases within pipelines.

Conclusion

In conclusion, cryogenic check valves are indispensable components in any system handling low-temperature fluids. Their unique design and functionality address the specific challenges posed by cryogenic environments, allowing for safe, efficient, and reliable operations across various industries. As advancements continue in technology and materials, the performance and applications of cryogenic check valves are likely to expand, further solidifying their importance in modern engineering. Whether in aerospace, medical, or industrial applications, these valves ensure that cryogenic systems function seamlessly, upholding the integrity of critical processes.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025