din butterfly valve manufacturer

The Importance of DIN Butterfly Valves in Industrial Applications

In the world of industrial processes, the significance of valves cannot be overstated. Among the various types of valves used, the DIN butterfly valve stands out due to its unique advantages and widespread applicability. As industries strive for efficiency, reliability, and precision, the demand for high-quality butterfly valves from reputable manufacturers is ever-increasing.

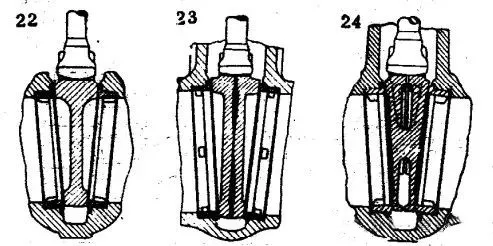

A DIN butterfly valve is a type of quarter-turn valve that utilizes a rotating disc to regulate the flow of fluids. The design allows for quick shut-off and is particularly effective in applications requiring a tight seal to prevent leaks. The term DIN refers to the German Institute for Standardization (Deutsches Institut für Normung), indicating adherence to specific quality and dimensional standards. This assurance of quality is paramount in industries such as oil and gas, water treatment, and power generation, where valve reliability is critical.

When selecting a butterfly valve manufacturer, several factors come into play. A reputable manufacturer will provide products that meet stringent international standards and undergo rigorous testing. This ensures that the valves can withstand the harsh conditions often encountered in industrial environments, including extreme temperatures, corrosive materials, and high-pressure scenarios.

One of the major benefits of DIN butterfly valves is their efficiency in terms of space and weight. Unlike gate or globe valves, butterfly valves have a compact design, making them ideal for installations with limited space. Their lightweight construction facilitates easier handling and installation, which can significantly reduce labor costs. This is particularly advantageous in large-scale operations where numerous valves may be required.

din butterfly valve manufacturer

Moreover, the ease of operation is another reason for the popularity of DIN butterfly valves. The quarter-turn design allows for smooth operation, enabling quick opening and closing mechanisms. This feature is crucial in emergency situations where rapid response can prevent accidents and safeguard personnel and equipment.

In addition to their operational efficiency, DIN butterfly valves boast a range of materials and configurations tailored to specific applications. From stainless steel to plastic options, manufacturers provide a variety of materials capable of resisting corrosion and wear over time. This adaptability makes them suitable for handling a wide array of media, including water, chemicals, and even slurries.

Furthermore, advancements in technology have enhanced the performance of butterfly valves. Modern manufacturing techniques allow for precision engineering, resulting in valves with improved durability and reliability. Features such as anti-cavitation and noise reduction technologies further ensure that the valves perform optimally under various operating conditions.

However, selecting the right DIN butterfly valve manufacturer is crucial for the successful integration of these components into any system. It is essential to consider the manufacturer’s experience, reputation, and customer support. A good manufacturer not only offers high-quality products but also provides technical support, ensuring that clients receive the correct solutions tailored to their needs.

In conclusion, DIN butterfly valves are an essential component in a wide range of industrial applications. Their unique design, coupled with the quality assurance provided by reputable manufacturers, makes them an optimal choice for many industries. As technology continues to advance, these valves will likely evolve further, enhancing their capabilities and applications even more. Therefore, it is imperative for businesses to invest in high-quality DIN butterfly valves and choose reliable manufacturers to meet their operational needs and maintain safe and efficient industrial processes.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025