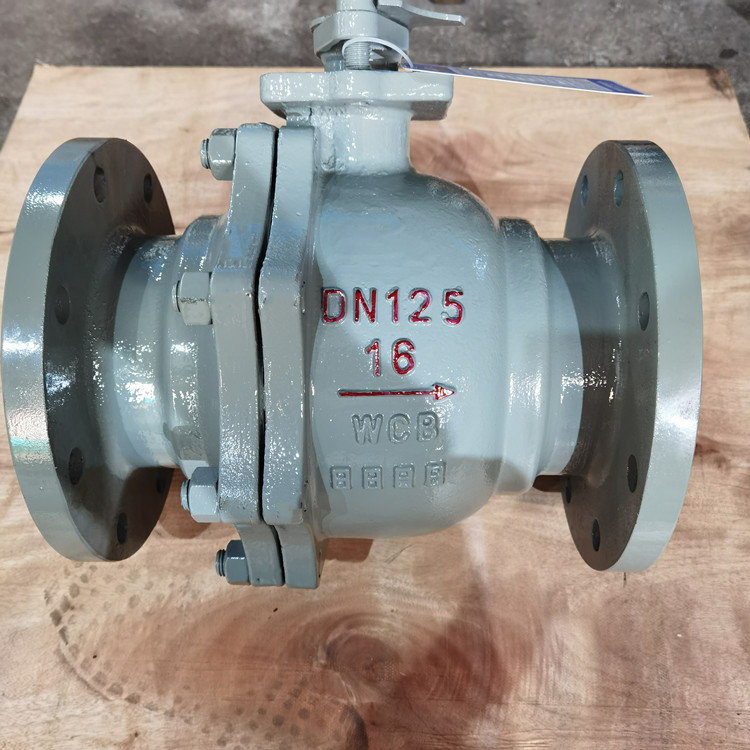

double check valve

The Importance of Double Check Valves in Fluid Systems

A double check valve is an essential component in many fluid systems, providing a critical line of defense against backflow, contamination, and pressure fluctuations. Often used in both residential and industrial applications, these valves play a vital role in maintaining the integrity and safety of water and other fluid supplies.

At its core, a double check valve consists of two independent check mechanisms that work in tandem to prevent reverse flow. Unlike a single check valve, which may fail if the internal mechanism becomes stuck, the double check valve’s redundancy ensures that if one valve fails, the second still provides protection. This design is particularly advantageous in applications where backflow could introduce contaminants into potable water supplies or industrial processes.

One of the primary applications of double check valves is in potable water systems to protect drinking water from being contaminated by pollutants. For instance, in irrigation systems, fertilizers and other chemicals may pose a risk if they were to flow back into the main water supply. By installing a double check valve, municipalities can ensure that even if there is a drop in pressure in the system, potentially harmful substances cannot enter the clean water supply. This compliance with health and safety regulations is critical to protecting public health.

double check valve

In industrial settings, double check valves are equally important. They help maintain consistent pressure levels within a system, preventing hydraulic shock and ensuring the smooth operation of machinery. In high-risk environments, such as chemical processing plants, double check valves are crucial for preventing the backflow of hazardous materials, which could lead to dangerous situations and costly clean-up efforts.

Installation of double check valves must be done according to local codes and standards, often requiring a professional plumber or technician to ensure that they are correctly positioned and functioning. Regular maintenance is also essential in keeping these valves operational. Periodic inspections and testing can identify any wear or damage, allowing for timely repairs or replacements to prevent system failures.

In conclusion, double check valves are an indispensable part of modern fluid systems, safeguarding against backflow and ensuring a consistent and safe flow of fluids. Their reliability, especially in critical applications, underscores the importance of proper installation, maintenance, and adherence to safety standards. For individuals and businesses alike, investing in high-quality double check valves is a proactive measure that can prevent costly accidents and maintain system integrity.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025