Top Manufacturers of Dual Plate Check Valves for Reliable Fluid Control Solutions

Understanding Dual Plate Check Valve Manufacturers and Their Importance

Check valves play a critical role in various industrial applications by preventing backflow and ensuring the smooth flow of fluids. Among the various types of check valves, dual plate check valves stand out due to their efficient design and operational benefits. This article explores the importance of dual plate check valve manufacturers and what sets them apart in the valve manufacturing industry.

What is a Dual Plate Check Valve?

A dual plate check valve, also known as a dual disc check valve, features two circular plates that open and close to regulate the flow of fluid. This innovative design allows for a lightweight structure, quicker response to changes in flow direction, and minimal pressure drop during operation. When fluid flows in the desired direction, the plates swing open, allowing for passage. When the flow attempts to reverse, the plates close under the force of gravity and fluid pressure, sealing the valve tightly to prevent backflow.

Significance of Dual Plate Check Valve Manufacturers

Manufacturers of dual plate check valves are essential for several reasons

1. Quality Assurance A reputable manufacturer focuses on producing valves that meet stringent quality standards. They utilize high-grade materials such as stainless steel, carbon steel, and special alloys to ensure durability and reliability in various operating environments. High-quality manufacturing processes not only guarantee the longevity of the valves but also ensure they can withstand extreme conditions in chemical processing, power generation, water treatment, and other demanding applications.

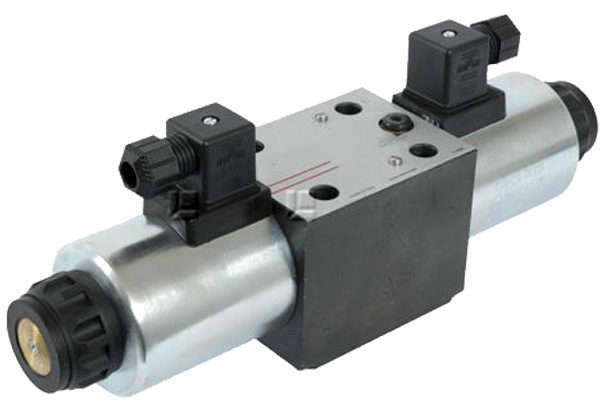

dual plate check valve manufacturers

2. Technological Innovation The industry sees constant advancements in valve design and technology. Established manufacturers invest in research and development to enhance valve performance, improve efficiency, and mitigate leaks. Innovations may include better spring systems for quicker closure times, designs that reduce cavitation, or applications of new materials that are resistant to corrosion and wear.

3. Customization Different applications demand different specifications. Leading check valve manufacturers offer customized solutions tailored to the specific needs of industries such as oil and gas, water management, and food production. This customization might include variations in size, pressure ratings, and end connections to ensure compatibility with existing systems.

4. Operational Efficiency Dual plate check valves are designed to minimize space and reduce weight without compromising their function. This is especially important in the context of modern industrial facilities that strive for a compact design while maintaining high performance. Manufacturers who understand these requirements can provide valves that enhance operational efficiency, reduce installation costs, and save on maintenance expenses.

5. Customer Support and Service The relationship between manufacturers and their clients does not end with the sale of a valve. Top manufacturers recognize the importance of robust customer support. They provide consulting services, installation guidance, and ongoing maintenance support. This commitment ensures that clients can maximize the lifespan and efficiency of their dual plate check valves, ultimately leading to improved operational reliability.

6. Sustainability Practices As the world increasingly focuses on sustainability, many dual plate check valve manufacturers are adopting eco-friendly practices. This includes using sustainable processes in manufacturing, reducing waste, and creating valves that help facilitate energy-efficient systems in industrial applications. Manufacturers are now taking initiatives to design valves that contribute to lower emissions and reduced environmental impact.

Conclusion

In summary, dual plate check valve manufacturers play a pivotal role in the industrial sector. Their dedication to quality, innovation, and customer support ensures that industries relying on fluid control systems operate smoothly and efficiently. By understanding the unique advantages offered by these manufacturers, companies can make informed decisions when selecting valves that meet their operational needs. As technology continues to advance, the role of these manufacturers will become increasingly vital in ensuring safe and effective fluid management solutions across various industries. As such, choosing the right manufacturer is essential not only for immediate operational proficiency but also for long-term sustainability.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025