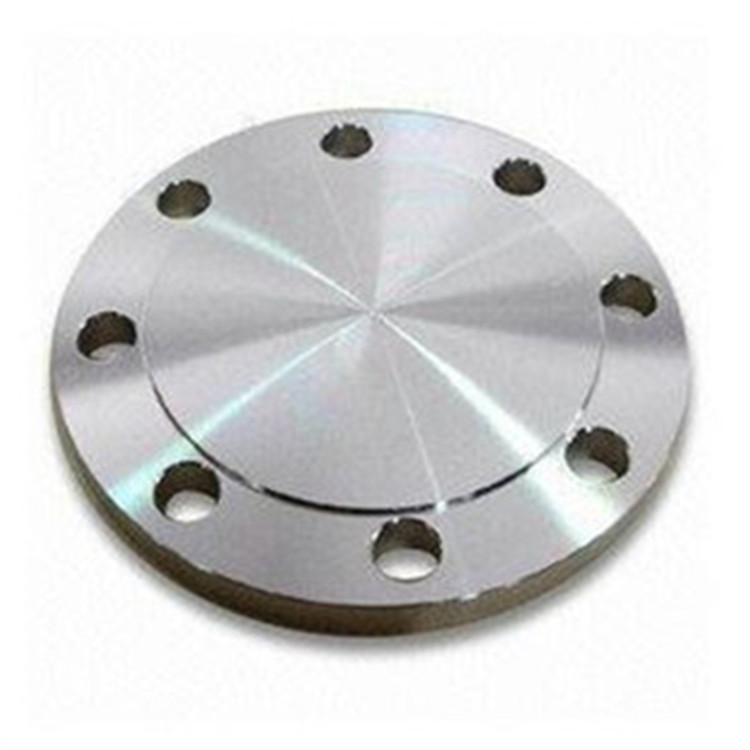

ductile iron gate valve manufacturer

The Rise of Ductile Iron Gate Valve Manufacturers An Overview

Ductile iron gate valves have become an essential component in various industrial applications due to their strength, durability, and resistance to corrosion. These valves are integral in controlling the flow of fluids in water supply systems, wastewater management, and various industrial processes, making the role of ductile iron gate valve manufacturers crucial in today's infrastructure development.

Understanding Ductile Iron

Ductile iron, also known as spheroidal graphite iron, is a type of cast iron known for its superior mechanical properties compared to traditional cast iron. This material is characterized by its enhanced strength, ductility, and wear resistance. The improved microstructure of ductile iron is achieved through the addition of small amounts of magnesium during the casting process, which transforms the flake graphite structure into nodular or spheroidal form. This innovative approach has led to the widespread use of ductile iron in manufacturing gate valves.

The Advantages of Ductile Iron Gate Valves

Ductile iron gate valves stand out for several reasons

1. Durability Ductile iron is known for its ability to withstand high pressures and temperatures, making it suitable for critical applications in various industries.

2. Corrosion Resistance Many ductile iron valves are coated with protective materials or treated with anti-corrosive finishes, significantly extending their lifespan and reducing maintenance costs.

3. Ease of Operation Gate valves are designed to facilitate smooth flow with minimal pressure drop. This characteristic makes them ideal for on/off applications where throttling is not a requirement.

4. Cost-Effectiveness Although the initial investment might be higher compared to other materials, the longevity and lower maintenance requirements of ductile iron gate valves often lead to overall cost savings in the long run.

ductile iron gate valve manufacturer

The Manufacturing Process

The manufacturing of ductile iron gate valves involves several critical steps

1. Melting and Casting Ductile iron is melted in a furnace and poured into molds to create the valve components. The casting process is carefully controlled to ensure the right balance of magnesium and other alloying elements.

2. Machining Once the castings have cooled and solidified, they undergo machining to achieve precise dimensions and tolerances. This step is crucial for ensuring the valves function correctly and fit seamlessly in piping systems.

3. Assembly After machining, the various components (body, bonnet, gate, and other internal parts) are assembled. Quality control measures are applied to ensure that every valve meets industry standards.

4. Testing Finally, each valve is thoroughly tested for pressure, leak performance, and operational functionality to ensure reliability in real-world applications.

The Market Landscape

The global ductile iron gate valve market is witnessing consistent growth, driven by urbanization, infrastructure development, and an increasing focus on water and wastewater management. Manufacturers are investing in research and development to improve the design and performance of their products, leading to innovations such as enhanced sealing technologies and smarter valve control systems.

Several key players dominate the market, focusing on expanding their product lines and improving quality standards. They are also committed to sustainable manufacturing practices, reducing carbon footprints, and promoting environmentally friendly solutions, in line with global trends toward sustainability.

Conclusion

Ductile iron gate valves are a vital part of modern infrastructure, with manufacturers playing a pivotal role in ensuring quality, durability, and performance. As industries continue to evolve and demand more robust solutions, the ductile iron gate valve market is poised for further innovation and growth. The expertise and commitment of manufacturers to deliver high-quality products will significantly contribute to the reliability and efficiency of critical water and fluid management systems worldwide.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025