Durable Cast Iron Flanged Gate Valve for Reliable Flow Control in Industrial Applications

Cast Iron Flanged Gate Valves A Comprehensive Overview

Cast iron flanged gate valves play a critical role in various industries, particularly in water supply, wastewater management, and chemical processing. Known for their durability and reliability, these valves are essential components for controlling the flow of liquids and gases in piping systems. This article delves into the features, applications, advantages, and maintenance considerations of cast iron flanged gate valves.

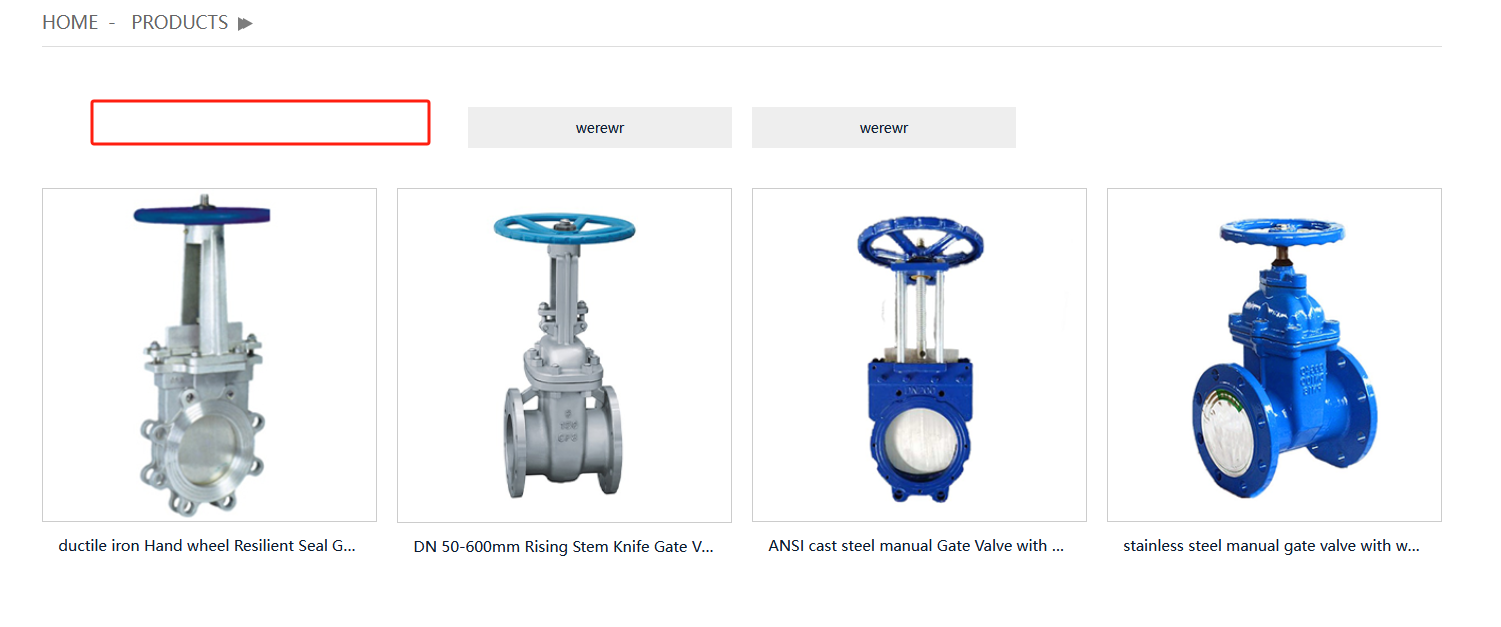

Understanding Cast Iron Flanged Gate Valves

Gate valves are designed for on-off control rather than throttling flow. They operate by lifting a gate (or wedge) out of the pathway of the fluid, allowing for unobstructed flow when the valve is fully open. The flanged design simplifies the installation process, as these valves can be easily secured to pipelines using bolts and nuts. Cast iron, a popular material for these valves, offers excellent strength and resistance to corrosion when properly coated or treated.

Key Features

1. Material Composition Cast iron is favored for its good mechanical properties and cost-effectiveness. It can withstand high pressures and provides good resistance against wear and tear.

2. Flanged Connections The flanged design allows for easy installation and removal, facilitating maintenance or replacement without the need for extensive disassembly.

3. Variety of Sizes Cast iron flanged gate valves come in various sizes to accommodate different piping systems, making them versatile for a range of applications.

4. Sealing Mechanism These valves typically employ a wedge or parallel slide design to ensure a tight seal when closed, minimizing leakage and fluid loss.

Applications

Cast iron flanged gate valves are widely used in many sectors, including

- Water Distribution They are critical in municipal water supply systems, ensuring controlled water flow from treatment plants to consumers. - Wastewater Management In sewage and effluent treatment facilities, these valves help regulate the flow into treatment processes.

- Chemical Processing Industries dealing with various chemicals use these valves to manage fluid flow safely, taking advantage of their robustness against corrosive substances.

cast iron flanged gate valve

- Power Generation In power plants, cast iron flanged gate valves control the flow of steam and water in cooling and steam generation systems

.Advantages

1. Durability Cast iron is known for its longevity, making these valves a cost-effective option over time, as they require less frequent replacement compared to other materials.

2. Low Maintenance With simple operation and a robust design, cast iron flanged gate valves tend to require minimal maintenance, thereby reducing operational costs.

3. High Flow Capacity When fully open, gate valves offer minimal resistance to flow, making them suitable for applications requiring high flow rates.

4. Cost Efficiency Compared to other materials like stainless steel, cast iron provides an economical solution without compromising on performance.

Maintenance Considerations

To ensure optimal performance and extend the lifespan of cast iron flanged gate valves, regular maintenance is vital. Here are some suggestions

- Regular Inspection Routine checks for leaks, corrosion, and wear can help detect issues early.

- Cleaning Keeping the valve and surrounding areas clean can prevent buildup that might hinder operation.

- Lubrication Periodic lubrication of the operating mechanism can facilitate smooth operation, especially in environments with fluctuating temperatures or humidity.

Conclusion

Cast iron flanged gate valves are essential components for various industrial applications, offering a blend of durability, reliability, and cost-effectiveness. Their ability to provide efficient flow control makes them a go-to choice in many settings. With proper maintenance and understanding of their features, users can maximize their benefits and contribute to the efficient operation of piping systems. Whether in water distribution, wastewater management, or chemical processing, these valves remain a cornerstone of fluid control technology.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025